Do you have a question about the Hamworthy Purewell Variheat mk2 110c and is the answer not in the manual?

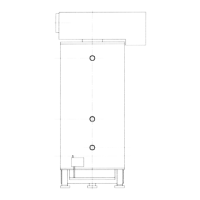

| Model | Purewell Variheat mk2 110c |

|---|---|

| Appliance Category | Boiler |

| Output (kW) | 110 |

| Fuel Type | Natural Gas |

| Mounting | Floor Standing |

Requirements for competent personnel and adherence to regulations for boiler installation.

Specifications and regulations for the gas supply connection to the boiler.

Recommendations for flue termination, routing, construction, and drainage.

Requirements for feed and expansion tanks, pipework, and water treatment.

Safety and installation requirements for the boiler's electrical supply.

Ensuring gas installation pipework is tested and purged correctly.

Procedure for checking the boiler's gas system for leaks before ignition.

Pre-ignition checks including gas supply, electrical connections, and safety limiters.

Step-by-step guide for safely lighting the boiler for the first time.

Testing safety interlocks and controller response during the ignition sequence.

Procedure for measuring and adjusting CO2 levels for optimal combustion.

Troubleshooting issues related to the safety temperature limiter tripping.

Diagnosing faults related to the burner ignition sequence and flame detection.

Recommendations for routine annual and bi-annual servicing of the boiler.

Recommended procedure for replacing the main gas valve assembly.

Information on the selection and location of safety valves for the system.

Loading...

Loading...