APRON SPEED AND BEATER CONTROL

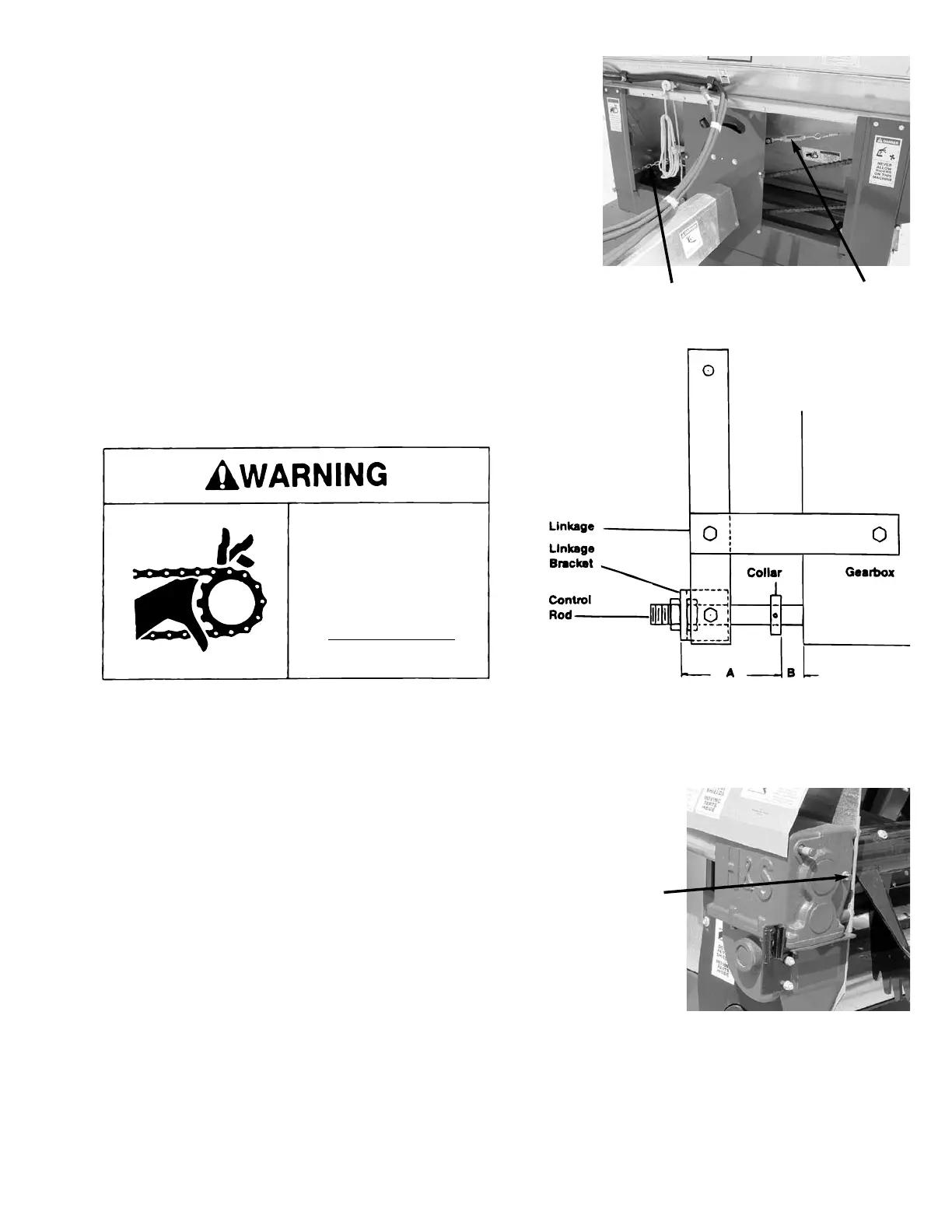

One cable controls the beater and apron drive two speed

gearbox. To compensate for wear or stretching of this cable

adjust turnbuckle behind shield at left hand front of spreader.

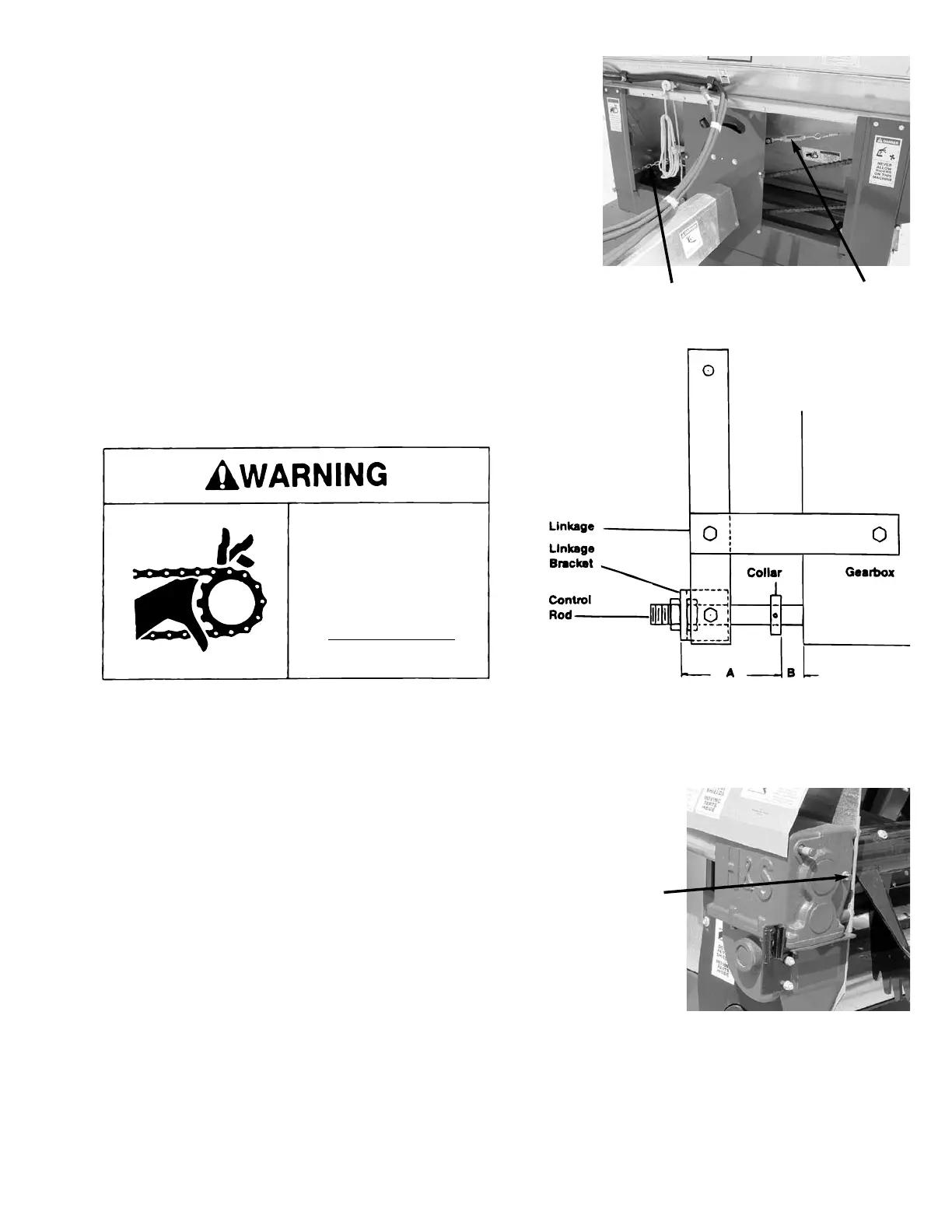

Refer to drawing to properly adjust manure spreader. Position

speed control in HI Speed. Measurement (A) is 2-1/2 inches.

This is factory set and should not be changed. Do not move

bracket or collar on control rod. The distance between collar

and face of gearbox should be as follows for the different

speeds: (distance B)

LO Speed: 0’’ (tight against gearbox)

HI Speed: 7/16-1/2’’

CLEAN OUT: 3/4-1 1/16’’

If Collar on control rod does not pull tight to gearbox in LO

Speed, after Hi Speed has been properly adjusted, apply

more tension to return spring behind shield at right hand front

of spreader. To adjust spring, hook end of spring one chain

link shorter on spring attaching chain.

-13-

GEARBOX – Before using your new machine, check the

oil in the main apron drive and beater drive gearbox.

Keep the gearbox filled to the oil plug on the rear of the

gearbox as shown with Mobilube SHC 75W90 (Or

Equivilant) gear lube.

DRIVE CHAINS – Lubricate the drive chains with a light

machine oil. Keep chains aligned with sprockets, this will

lengthen the life of the sprockets and chain. Lubricate

chains often.

Attaching Chain Turnbuckle

DO NOT CLEAN

OR WORK ON THIS

MACHINE WITHOUT

FIRST DISENGAGING

POWER AND

SHUTTING OFF

TRACTOR ENGINE.

LUBRICATION GUIDE

The operator should become familiar with all lubrication points and establish a systematic routine to insure

complete and quick lubrication of the machine.

GREASE FITTINGS – There are eleven grease fittings on the spreader, thirteen, if equipped with hydraulic

endgate. If these are lubricated properly and often enough, it will prolong the life of the spreader. (Grease

every 20 hours, also before storage and after power washing.) Make certain that the grease fittings are free

of paint and dirt, force a high-quality grease into them until the grease comes out around the shaft on the

sleeve-type bearings. On the sealed ball bearings, grease should be added slowly until a slight bead forms

at the seals indicating the correct amount of lubricant. Wipe off excess grease to prevent the accumulation

of chaff and grit around the bearings. (See page 14 for grease zerk location.)

OIL LEVEL

Loading...

Loading...