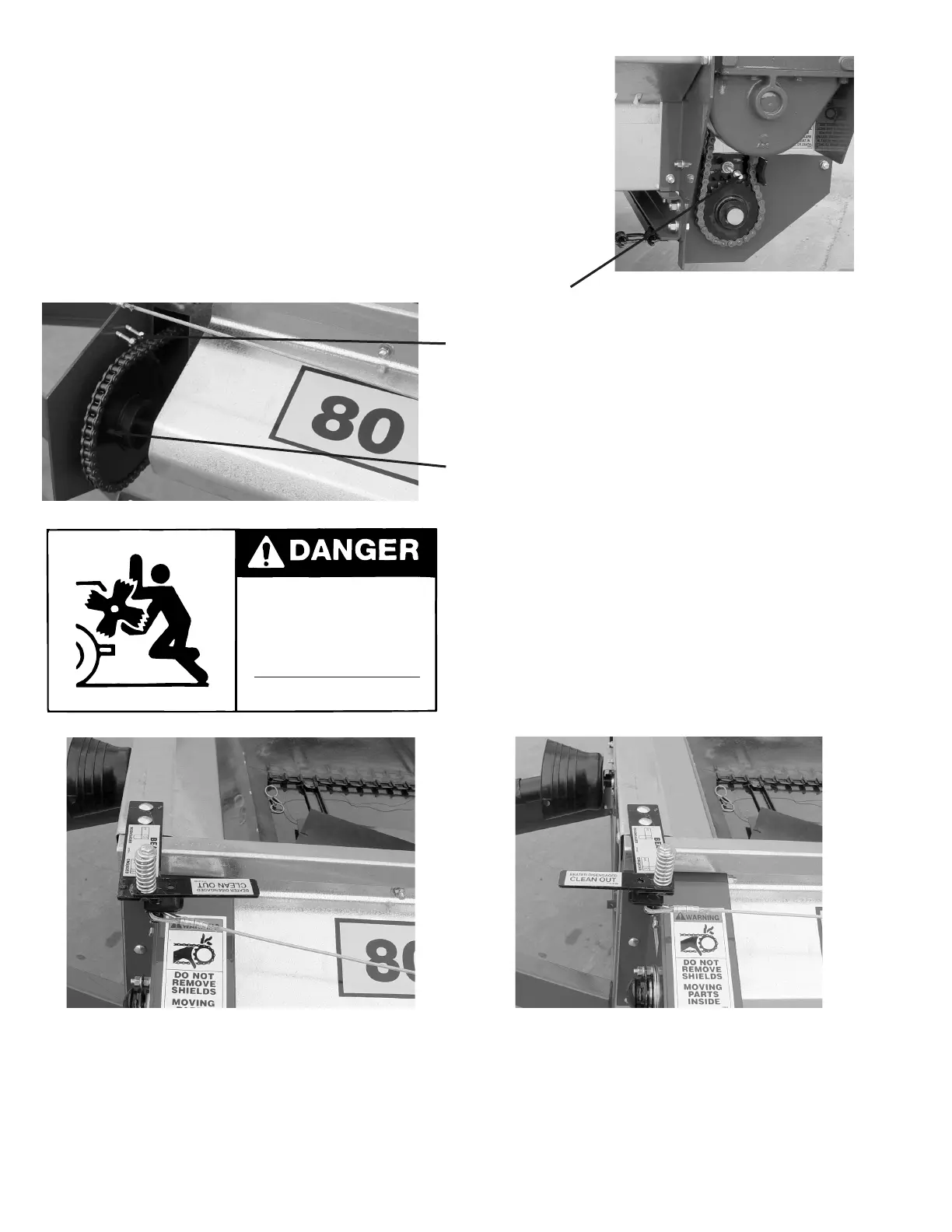

APRON DRIVE CHAIN

Maintain proper tension on the apron drive chain. There should be 1/4

inch deflection at the side of the chain when properly adjusted. To

adjust loosen bolt holding tightener. Slide tightener against drive chain

and retighten bolt. Failure to maintain proper tension will result in

excessive wear to chain and sprockets.

SHEAR BOLT

The beater and apron drive are protected by one shear bolt. Two shear

bolts are provided. Shearing of the bolt is normally due to foreign

objectsin the manure, or starting the spreader PTO too quickly with

high tractor RPM’s. Always use H&S shear bolts, part number

16SV289, when replacing shear bolts.

-12-

ADJUSTING WHEEL HUBS

To adjust the wheel hubs, tighten the

castellated nut on the spindle to the point

where there is no end-play and a slight

drag on the bearings, and replace the

cotter key with a new one of the correct

size.

FAILURE TO FOLLOW THE REC-

OMMENDED ADJUSTMENTS WILL

VOID WARRANTY.

BEATER

As the beater paddles are welded to the beater tube, replacement of these paddles should be performed by

authorized service personnel who are competent welders. When replacing paddles, the sharp edge of the

teeth must lead in the direction of beater travel.

When transporting on the highway, regularly clean the reflective tape at the rear of the spreader. There is a

holder provided for your SMV sign.

Shields Removed For Clarity

TIGHTENER

BOLT

SHEAR

BOLT

SPARE

SHEAR

BOLTS

STAY CLEAR OF BEATER IF

TRACTOR OR PTO IS RUNNING

BEATER SHUT OFF COULD

ACCIDENTALLY BE ENGAGED

FAILURE TO HEED THIS

WARNING MAY RESULT IN

PERSONAL

INJURY OR DEATH

KEEP CLOTHING, YOURSELF

AND OTHERS WELL CLEAR

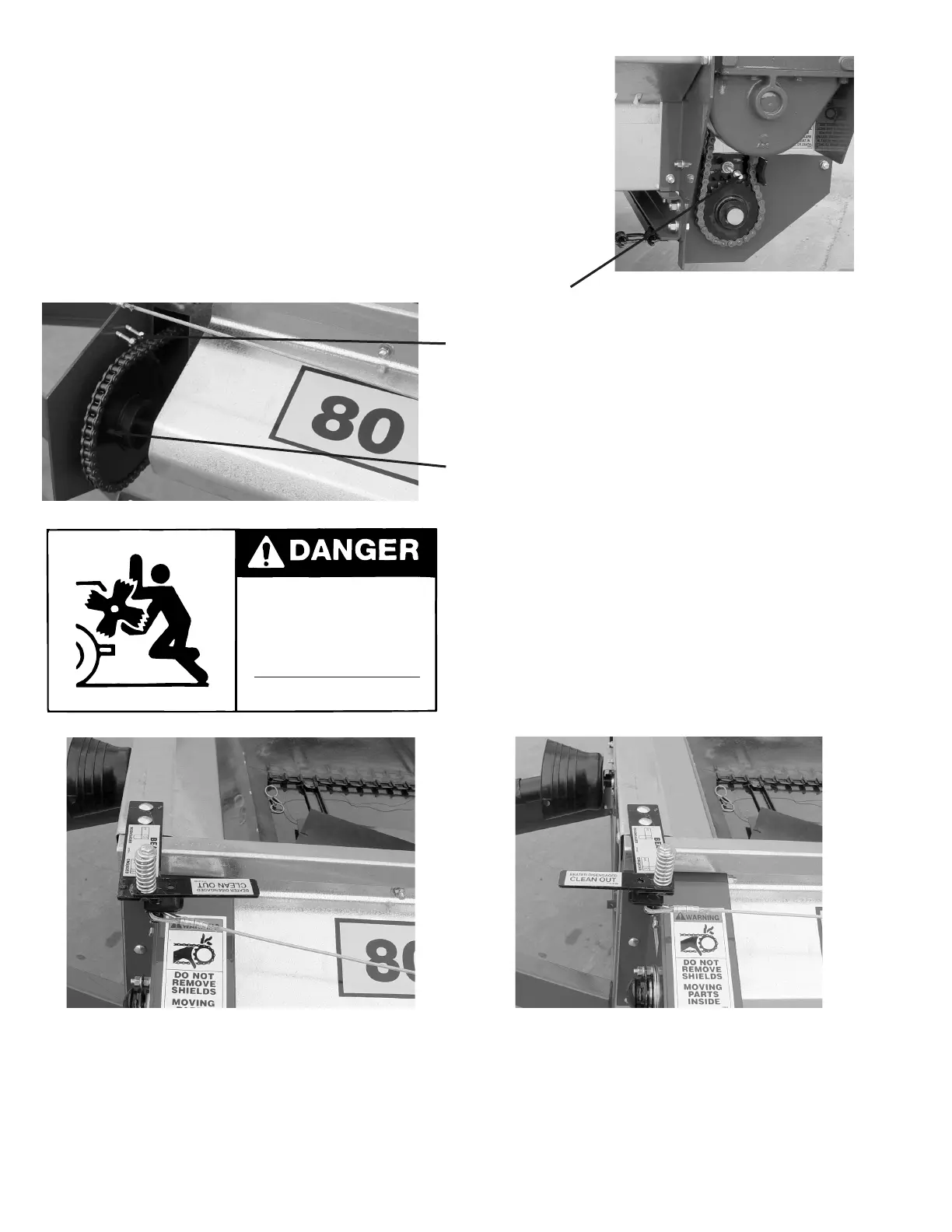

BEATER CONTROL

The beater engage / disengage handle

is located at the front left hand side of

the spreader. NEVER engage or disen-

gage beater with PTO engaged.

Beater Engaged Beater Disengaged

Loading...

Loading...