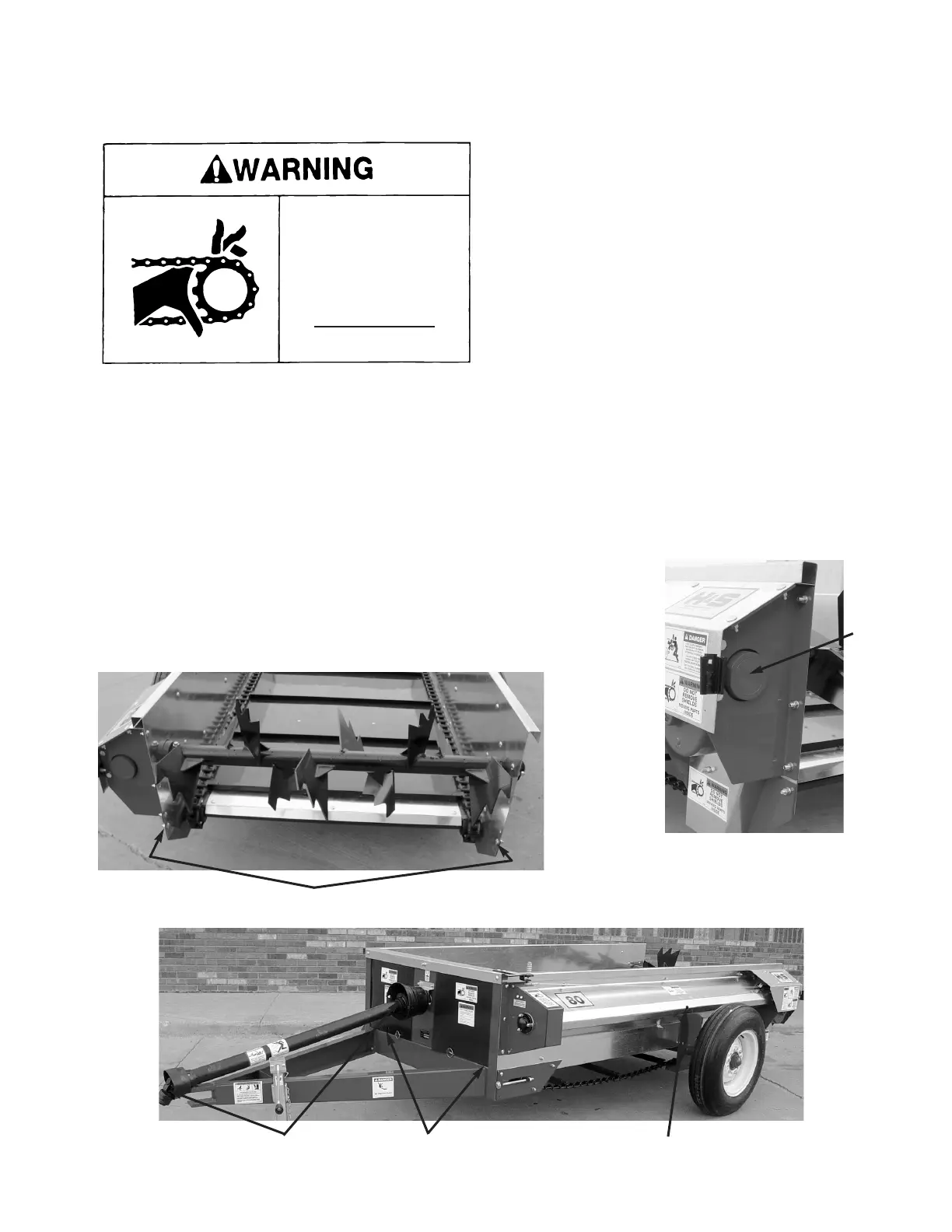

LUBRICATION GUIDE MODEL 80

(FOR MODEL 125 SEE PAGE 17)

The operator should become familiar with all lubri-

cation points and establish a systematic routine to

insure complete and quick lubrication of the

machine.

DRIVE CHAINS–Lubricate the drive chains with a

light machine oil. Keep chains aligned with

sprockets. This will lengthen the life of the sprock-

ets and chain. Lubricate chains often.

GEARBOX–Before using your new machine,

check the oil level in the gearbox located at the

left rear of the spreader. Keep the gearbox filled to

the center of the top shaft of the gearbox with

80-90 gear lube.

-13-

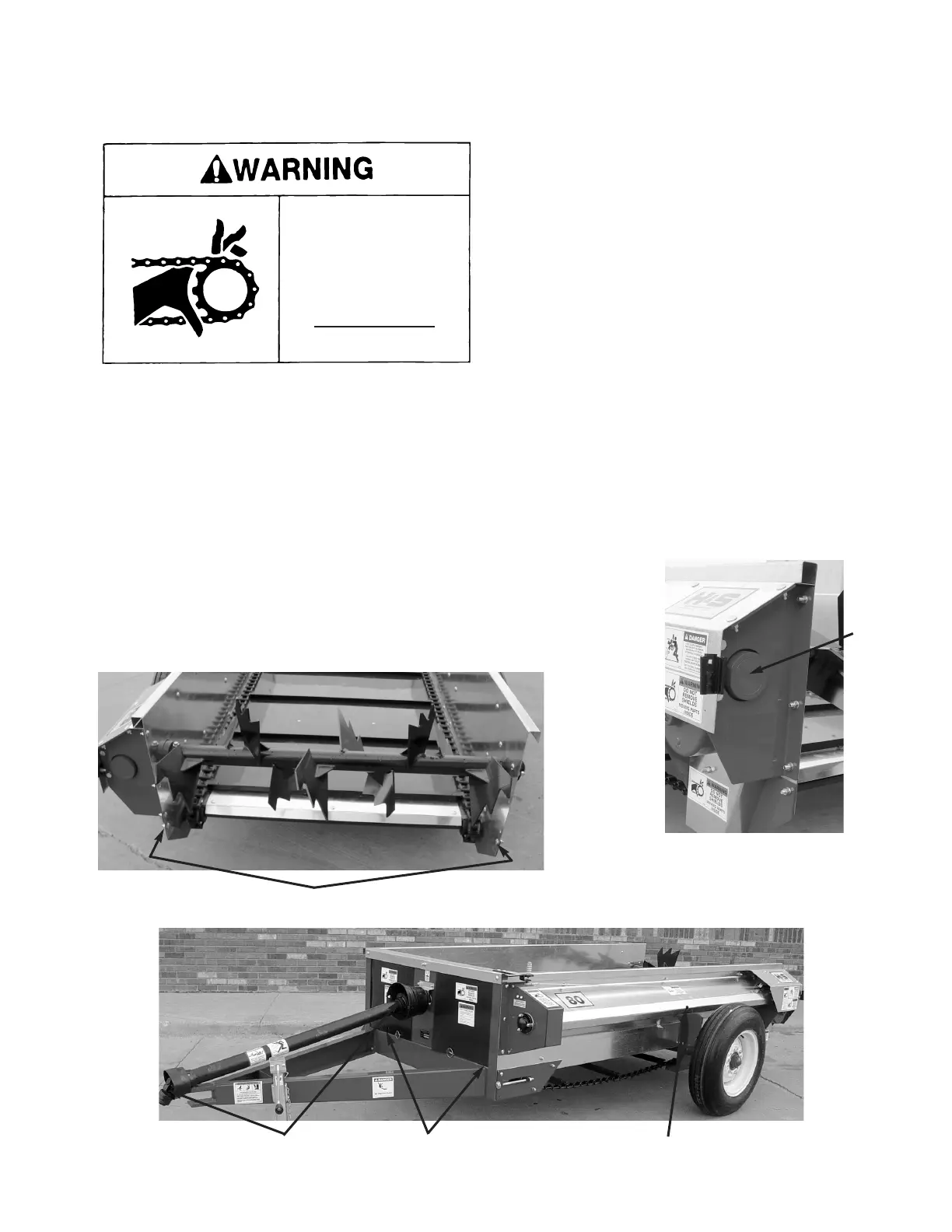

Shields Removed

for Clarity

DO NOT CLEAN

OR WORK ON THIS

MACHINE WITHOUT

FIRST DISENGAGING

POWER AND

SHUTTING OFF

TRACTOR ENGINE.

OIL

LEVEL

GREASE FITTINGS – (Location)

A. (2) One at each end of PTO shaft C. (1) On the side shaft

B. (2) One on each idler sprocket D. (2) On each end of drive shaft

A B C

D

There are 7 grease fittings on this spreader. If these are lubricated properly and often enough it will prolong

the life of the spreader (Grease every 20 hours, also before storage and after power washing). Make cer-

tain that the grease fittings are free of paint and dirt, force a high quality grease into them until the grease

comes out around the shaft on the sleeve type bearings. On the sealed ball bearings, grease should be

added slowly until a slight bead forms at the seals, indicating the correct amount of lubricant. Wipe off

excess grease to prevent the accumulation of chaff and grit around the bearings.

Loading...

Loading...