-14-

OPERATION MODEL 125

1. Check for proper assembly and adjustment and make sure that all bolts are tightened. Securely

retighten after a few hours of operation, as bolts can loosen up on new machinery. Check wheel bolts

upon delivery and periodically thereafter. Wheel bolts should be tightened at 60-65 ft./lbs. of torque.

2. Check the tires and inflate to the recommended pressure (10:00 x 15 tires to 40-50 pounds).

3. Adjust the tractor hitch and attach the spreader to the tractor as described in the following sections.

4. Lubricate the machine completely and check the oil level of the gearbox.

5. Before operation run machine slowly to make sure that the spreader is operating and lubricated

properly.

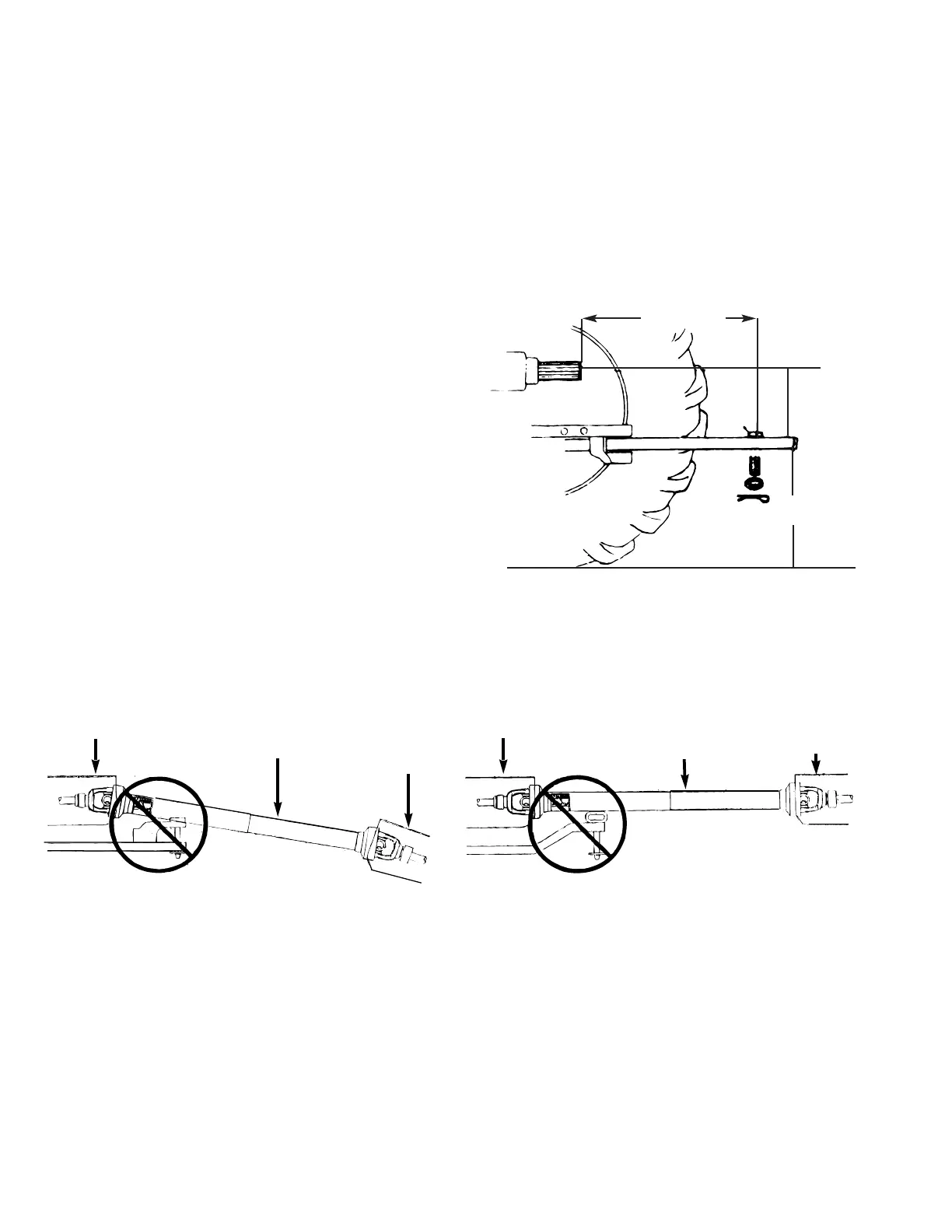

TRACTOR HITCH

The hitch of the spreader is designed for a stan-

dardized tractor hitch. Adjust the drawbar so that it

is 13 to 17 inches above the ground. Extend or

shorten it so that the horizontal distance from the

end of the tractor power takeoff shaft to the center

of the hitch pin hole is 14 inches, as shown in draw-

ing. Use an adapter plate, if necessary, to secure

the proper distance. An improperly located hitch

point may cause damage to the universal joints of

the power takeoff. Secure the drawbar so that the

hitch pin hole is directly below the power drive line.

ATTACHING TO THE TRACTOR

1. Fasten the spreader hitch to the drawbar with a hitch pin that cannot bounce out. Use 3/4’’ to 7/8’’

diameter hitch pin to pull spreader.

2. Remove the weight from the jack (jack is not to be used when spreader is loaded). Swing jack forward

into its horizontal position, and lock it to provide a maximum ground clearance.

3. Depress the spring loaded pin on PTO yoke and slide it on to the tractor PTO shaft. Be sure the pin

falls into the groove of the PTO shaft.

CAUTION: Do not use a steel hammer to aid in joining PTO

parts.

Be certain to disconnect all sources of power before servicing. Keep pant cuffs and other loose clothing

away from all chain and gear drives as well as the other moving parts. Keep off the equipment when in use,

and keep all safety shields in place; do not attempt to clean, grease or lubricate while the machine is run-

ning. Never allow riders in or on the machine.

14’’ FOR 540 RPM

12’’

13’’ TO 17’’

FROM GROUND

HITCH

BOLT

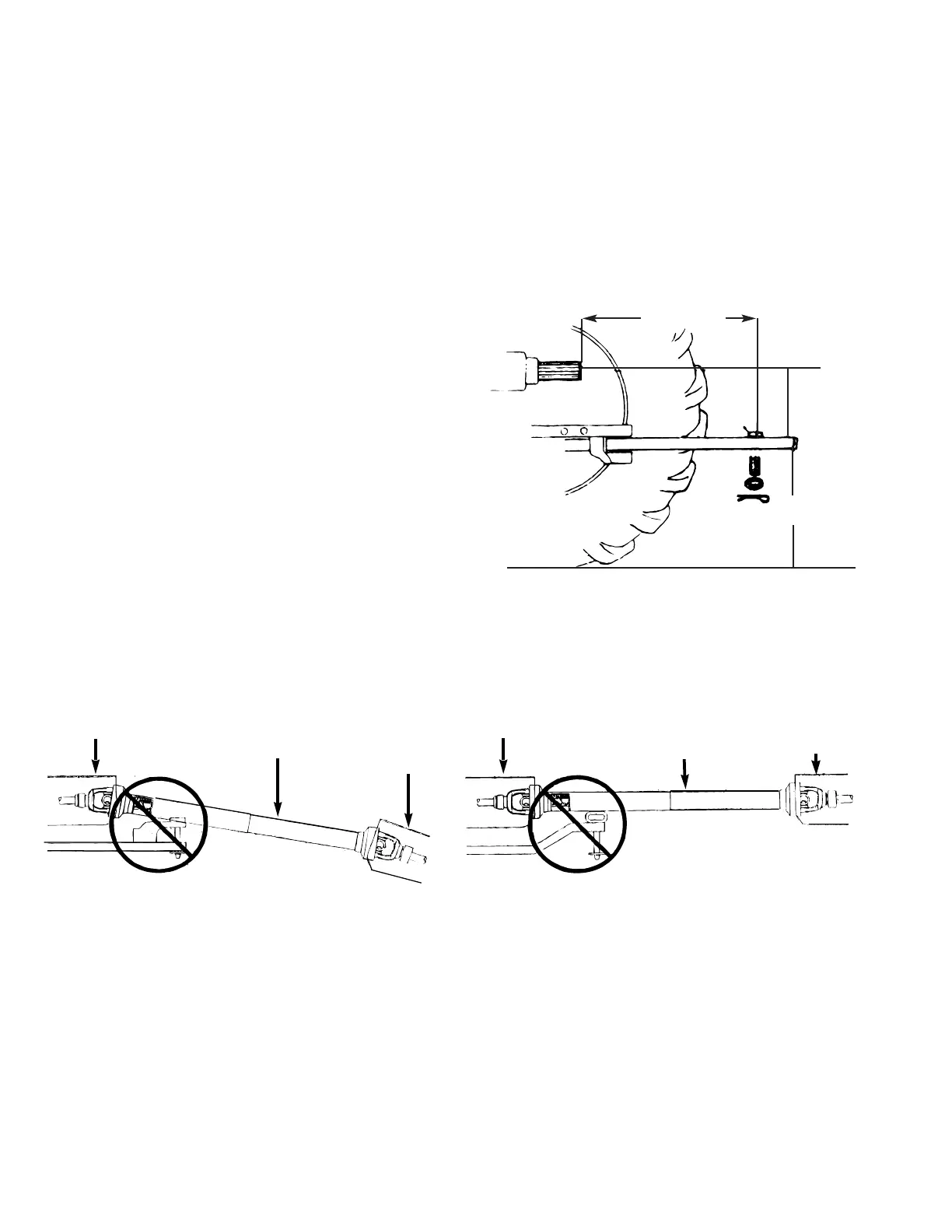

WRONGWRONG

FIGURE 1

TRACTOR MASTER SHIELD

IMPLEMENT INPUT

DRIVELINE (IID)

IMPLEMENT INPUT

CONNECTION

SHIELD (IIC)

TRACTOR MASTER SHIELD

IMPLEMENT INPUT

DRIVELINE (IID)

IMPLEMENT INPUT

CONNECTION

SHIELD (IIC)

If this implement is attached to a tractor with a clevis

hitch (hammer-strap) style drawbar, the hammer-strap

must be removed to prevent damage to the IID guarding

and the IID telescoping members. [See Figure 1]

If this implement is attached to a tractor with an offset in

the drawbar, be certain it is in the down position to pre-

vent damage to the IID guarding and the IID telescoping

members. [See Figure 2]

FIGURE 2

Loading...

Loading...