1-14 2005 PDI: All Models

VEHICLE CLEANUP

1WARNING1WARNING

Do not let the brakes, engine, mufflers or air cleaner get

wet when washing your motorcycle. Allowing these com-

ponents to get too wet can adversely affect their perfor-

mance, which could result in death or serious injury.

Start engine immediately after washing, and make sure

brakes and engine are operating properly before riding in

traffic. (00078b)

CAUTION

Avoid spraying water directly on handlebar switches. Wet

handlebar switches may be inoperative.

Remove protective shipping tape from motorcycle. Wash

entire motorcycle before beginning actual predelivery inspec-

tion. If vehicle is equipped with frame downtube reflectors,

remove any plastic cable straps wrapped around reflectors

(cable straps are used during assembly at factory for retain-

ing reflectors to downtubes while reflector adhesive cures).

COSMETIC QUALITY

Paint Finish Inspection and Repair

Under good lighting conditions, examine all painted parts for

any damage or irregularities in the paint finish. To aid the

dealer network in addressing quality concerns, Harley-David-

son Motor Company has developed a zoning and criteria pro-

tocol, which enables us to exceed customer’s expectations. If

you discover any condition requiring repair, use Paint Repair

Kit (Part No. HD-39994); available through Kent-Moore, at the

following address, to correct the condition.

Kent-Moore

28635 Mound Rd

Warren, Michigan 48092-3499

(phone) 1-800-345-2233

Instructions covering painted part repair are included with the

Paint repair Kit. Additional paint repair information is available

from Harley-Davidson on the PHD training videotape No. 136.

Additional cosmetic quality information is available in the Har-

ley-Davidson Cosmetic Booklet (Part No. HD-99514-05) and

on-line Cosmetic Training located on HDU On-line.

RETURNING STEEL PALLETS

NOTE

International Dealers/Distributors should check with their H-D

office to determine whether or not to return pallets.

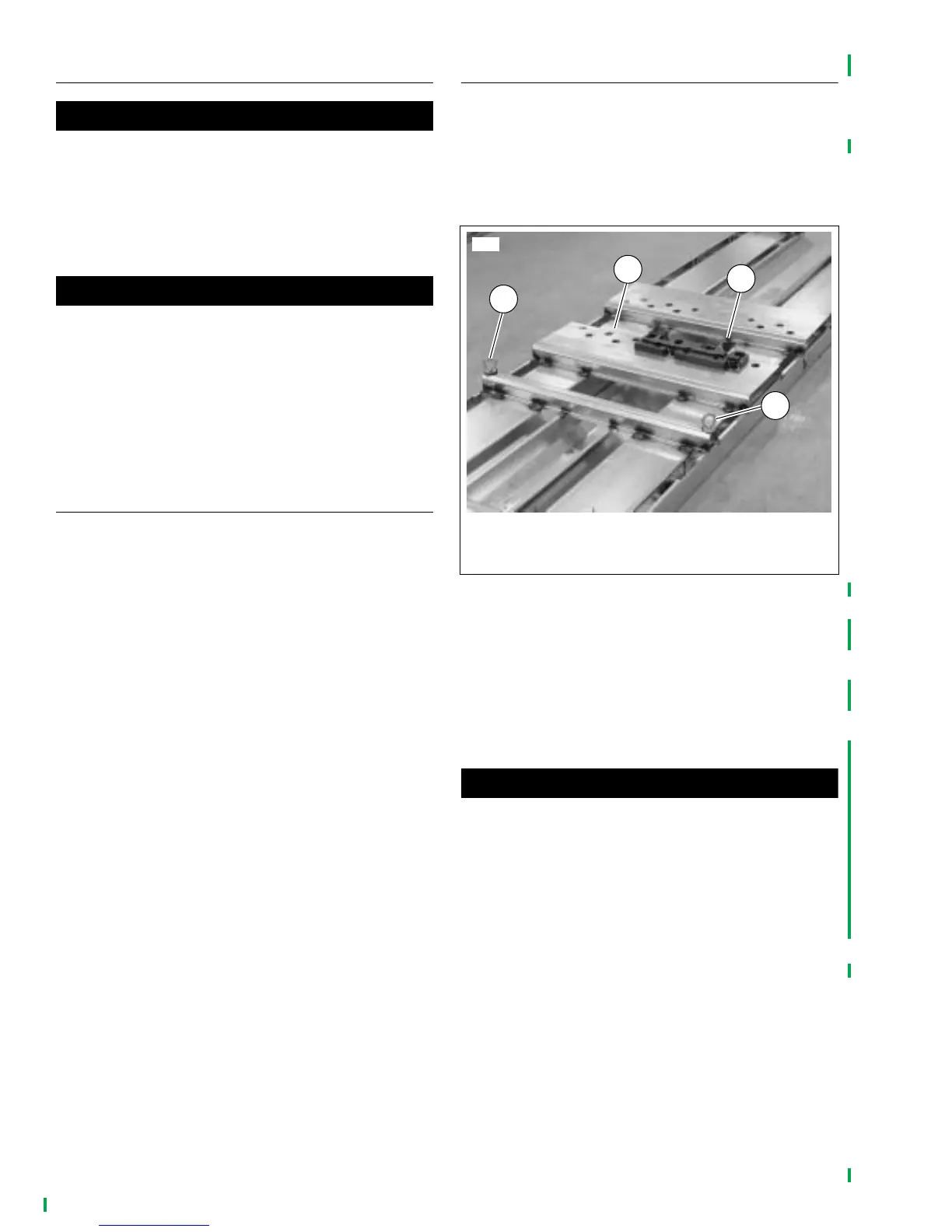

1. See Figure 1-26. Remove and discard plastic motor shim

(1).

2. Turn eye-bolts (2) so they are parallel with sides of pallet.

This will allow stacking pallets for shipment.

NOTE

On VRSC pallets place eye-bolt from rear in enclosed area

(3) of pallet.

3. Place hold-down straps you are returning to factory in

enclosed area (3) of pallets.

CAUTION

Do not mix 29 in. (736.6 mm) width pallets with 43 in.

(1.09 m) width pallets on the same 7-pallet stack. Mixing

pallets of different width could result in an unstable bun-

dle and pallet damage.

4. Stack seven pallets keeping all eye-bolts on same end.

5. Band pallets by threading hold-down straps through both

end cross members of top and bottom pallets. (If neces-

sary connect two straps together.)

6. Tighten straps to secure pallet bundles.

7. Call, Fax, E-mail or use www.h-dnet.com to arrange

pallet return to Harley-Davidson.

Figure 1-26. Vehicle Pallet

1. Plastic motor shim

2. Eye-bolts

3. Enclosed area

7770

2

3

1

2

Loading...

Loading...