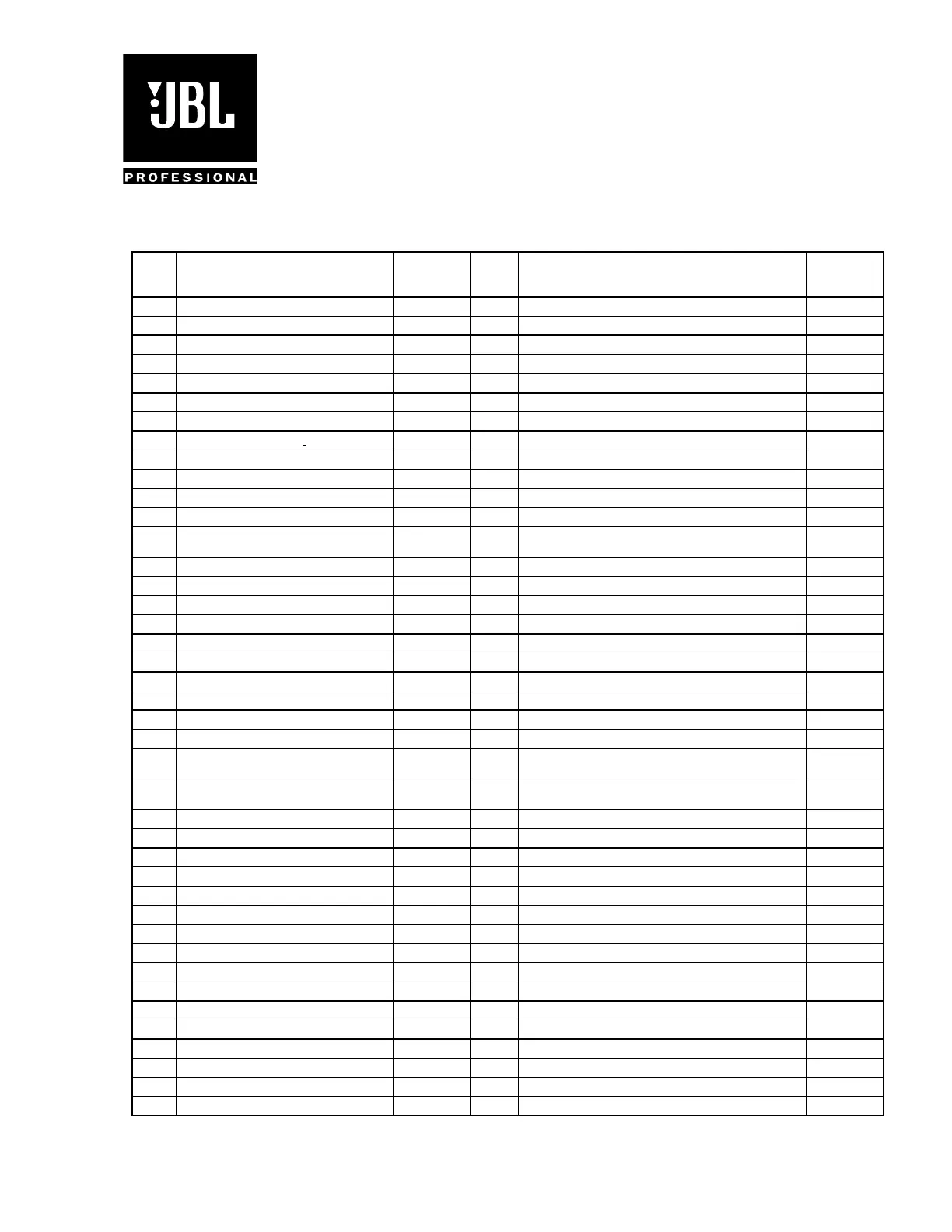

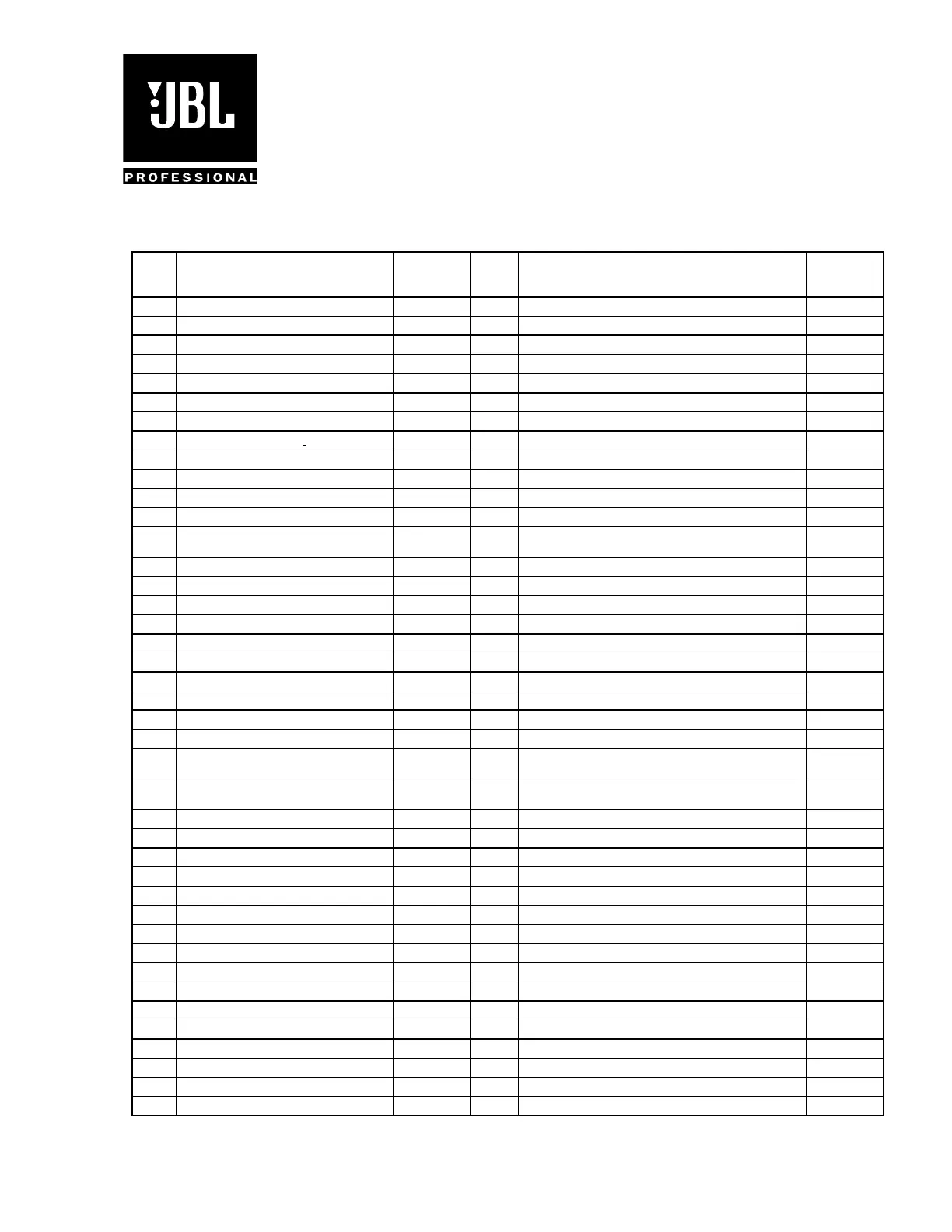

JBL PROFESSIONAL

LOUDSPEAKERS AND LOUDSPEAKER SYSTEM

Q.A. CODES

27

July 1, 2004

Page 1

Q.A.

CODE

DESCRIPTION OF DEFECT WARRANTY

STATUS

Q.A.

CODE

DESCRIPTION OF DEFECT WARRANTY

STATUS

0.0 No Defects - Definition 3.11 Open – Break at Eyelet IN

0.1 No Defects - Unclassified 3.12 Open - Solder Joint at Eyelet IN

0.2 No Defects - Standard 3.13 Open - Solder Joint at Terminal IN

0.3 No Defects - Non Standard 3.14 Open - Loose Terminal IN

0.4 No Defects - Retrofit 3.15 Open - Voice Coil Pulled Loose IN

0.5 No Defects - Not Accepted 3.16 Open - Voice Coil Driven Out of Gap OUT

3.17 Open - Voice Coil Burned (indicate burn type) OUT

1.1 Rubbing - Unclassified (Specify)

3.18 Open - Voice Coil Burned at Crossover OUT

1.2 Rubbing - High Wire IN 3.19 Open - Voice Coil Inside - Bubbled Support IN

1.3 Rubbing - Voice Coil Pulled Loose IN 3.20 Open - Burned Lead OUT

1.4 Rubbing - Crossover Lead IN 3.21 Open - Tinsel Lead IN

1.5 Rubbing - Excess Glue IN 3.22 Open - Tinsel Lead Oxidized OUT

1.6 Rubbing - Sunken Spider IN 3.23 Open - Diaphragm Overdriven (indicate damage to

diaphragm)

OUT

1.7 Rubbing - Cone Fatigue OUT 3.24 Open - Beryllium Copper Lead (indicate location break) IN

1.8 Rubbing - Torn Cone IN 3.25 Open - Voice Coil Lead IN

1.9 Rubbing - Torn Cone at Compliance IN 3.28 Open - Ferro Fluid Drift IN

1.10 Rubbing - Spider Loose at Frame IN

1.11 Rubbing - Spider Loose at Cone IN

4.1 Shorted - Unclassified (Specify)

1.12 Rubbing - Dented Dome OUT 4.2 Shorted - Voice Coil Turns IN

1.13 Rubbing - V.C. Driven Out of Gap * OUT 4.2 Shorted - Voice Coil Turns: Rubbing IN

1.14 Rubbing - Off Center Spider IN 4.4 Shorted - Voice Coil to Pot Frame IN

1.15 Rubbing - Chips in the Gap IN 4.5 Shorted - Tinsel Leads (touching) IN

1.16 Rubbing - Voice Coil Out of Round IN 4.6 Shorted - Voice Coil to Crossover Lead IN

1.17 Rubbing - Voice Coil Inside - Bubbled

Support

IN

1.18 Rubbing - Voice Coil Burned (indicate

type of burn)

OUT

5.1 Defective Bond - Unclassified (Specify)

1.19 Rubbing - Torn Spider IN 5.2 Defective Bond - Voice Coil Support to Diaphragm IN

5.3 Defective Bond - Dome IN

2.1 THRU 5.4 Defective Bond - Compliance (include CT) IN

2.18 SAME AS ABOVE FOR RUBBING 5.5 Defective Bond - Lansaloy IN

2.1 WITH PRESSURE 5.6 Defective Bond - Spider Inside IN

5.7 Defective Bond - Spider Outside IN

3.1 Open - Unclassified (Specify)

5.8 Defective Bond - Compliance at Cone IN

3.2 Open - Break at Crossover Lead IN 5.9 Defective Bond - Compliance Deterioration OUT

3.3 Open - Break at Weld IN 5.10 Defective Bond - Cone IN

3.4 Open - Internal Break in Voice Coil IN 5.11 Defective Bond - (Loose/Shifted) Magnet IN

3.5 Open - Break at Start Winding Bend IN 5.12 Defective Bond - Loose Voice Coil Mass Ring IN

3.6 Open - Break at Finish Winding Bend IN

3.7 Open - Break at V.C. Tube Inside IN

6.1 External Damage - Unclassified (Specify)

OUT

3.8 Open - Break at V.C. Tube Outside IN 6.2 External Damage - Dome OUT

3.9 Open - Break at Cone Collar IN 6.3 External Damage - Cone OUT

3.10 Open - Break at Cone Collar Finish Lead IN 6.4 External Damage - Frame Broken OUT

Loading...

Loading...