28 – English

MAINTENANCE

TOP PLATE FILING ANGLE

See Figure 35.

CORRECT30°-Fileholdersaremarkedwith

guidemarks to align file properlyto produce

correcttopplateangle.

LESSTHAN30°-ForCrossCutting.

MORETHAN30°-FeatheredEdgeDullsQuickly.

SIDE PLATE ANGLE

See Figure 36.

CORRECT-80° Producedautomaticallyifcor-

rectdiameterfileisusedinfileholder.

HOOK-“Grabs”anddullsquickly.Increases

potentialofKICKBACK.

Resultsfromusingafilewithdiametertoosmall,

orfileheldtoolow.

BACKWARDSLOPE - Needs too muchfeed

pressure,causes excessive wear to bar and

chain.

Resultsfromusingafilewithdiametertoolarge,

orfileheldtoohigh.

DEPTH GAUGE CLEARANCE

See Figure 37 - 39.

The depthgauge should be maintainedat a

clearanceof.025in.Useadepthgaugetool

forcheckingthedepthgaugeclearances.

Everytimethechainisfiled,checkthedepth

gauge clearance.

Useaflatfileandadepthgaugejointertolower

allgauges uniformly. Depth gauge jointers are

availablein.020in.to.035in.Usea.025in.depth

gaugejointer.Afterloweringeachdepthgauge,

restoreoriginalshapebyroundingthefront.Be

carefulnottodamageadjoiningdrivelinkswith

theedgeofthefile.

Depthgaugesmustbeadjustedwiththeflatfilein

thesamedirectiontheadjoiningcutterwasfiled

withtheroundfile.Usecarenottocontactcutter

facewithflatfilewhenadjustingdepthgauges.

LUBRICATING HOLE

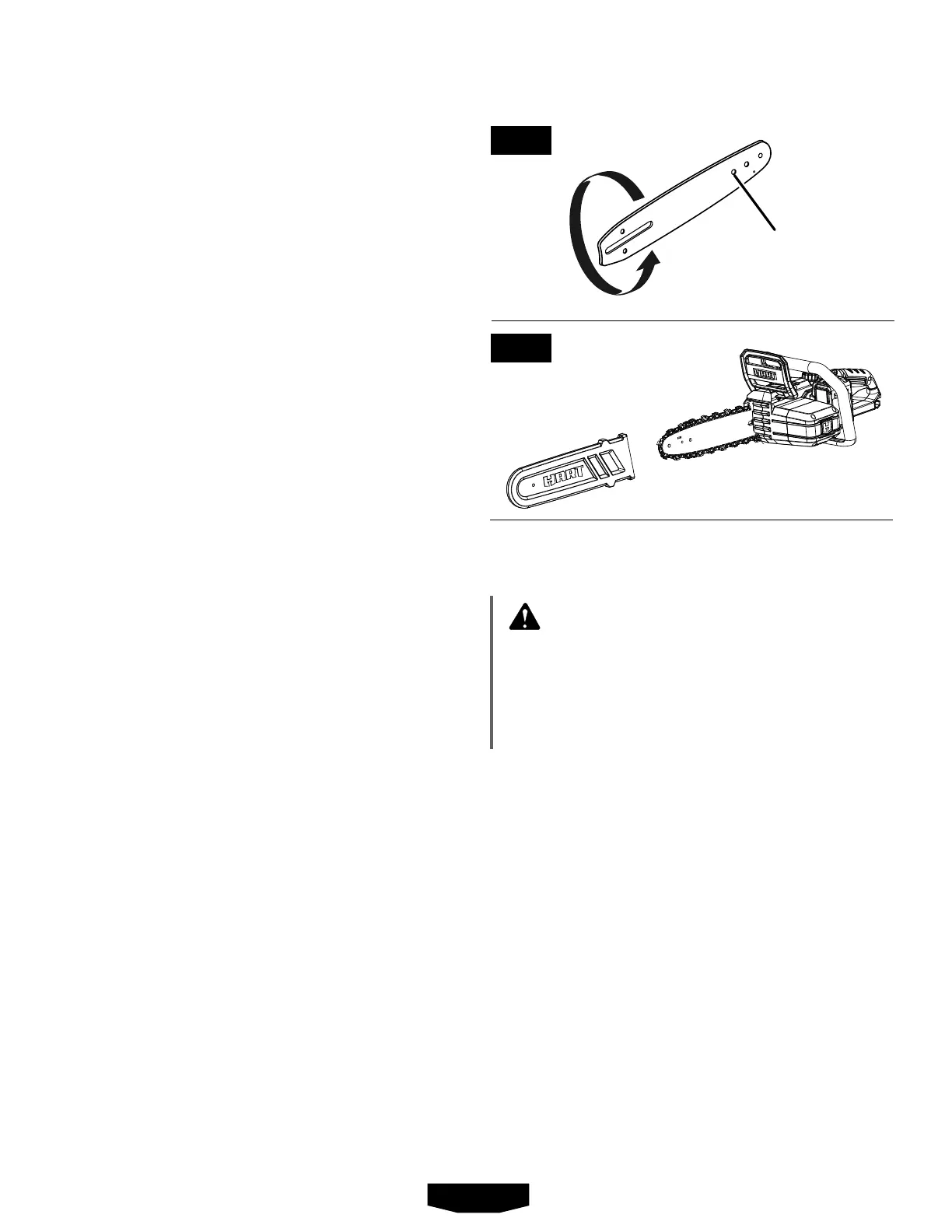

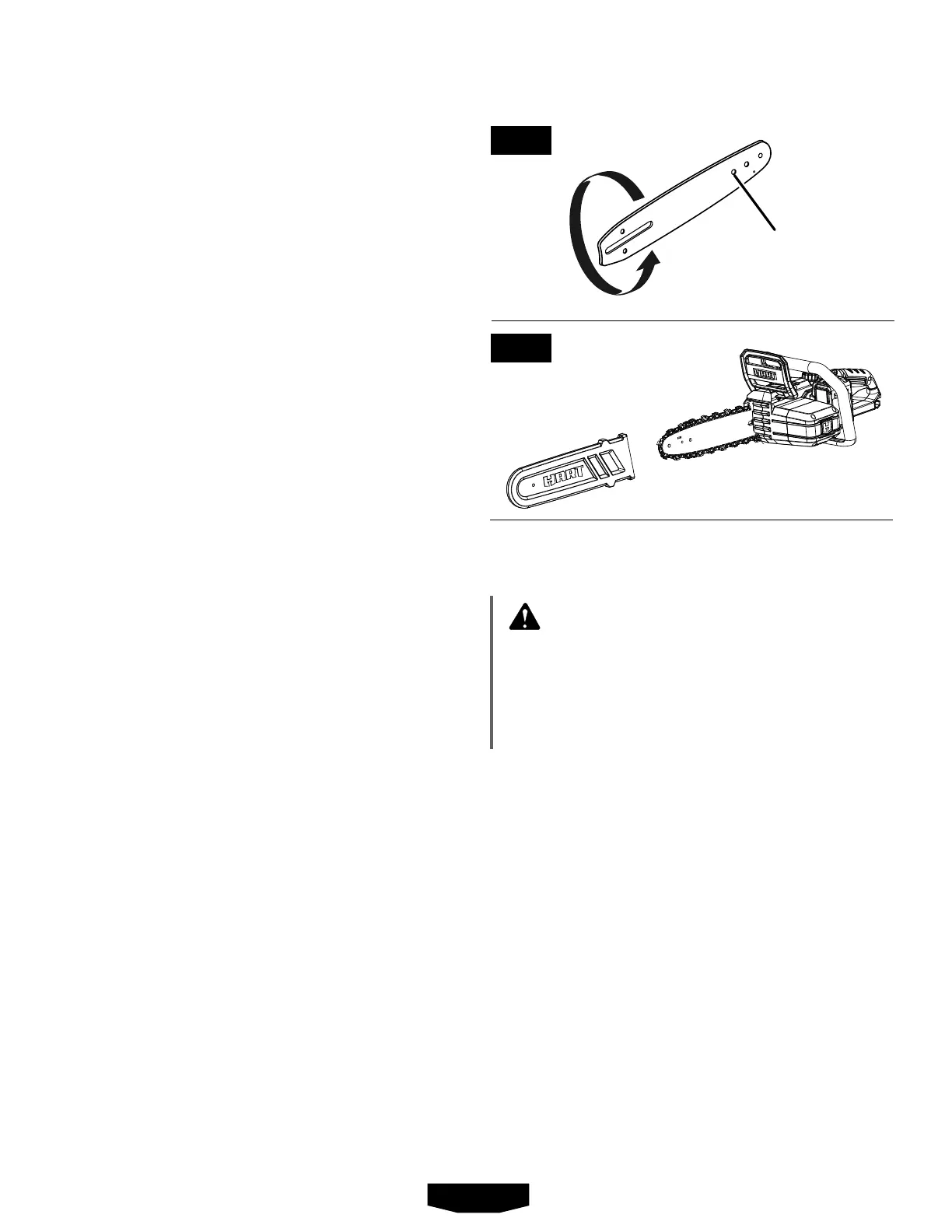

MAINTAINING THE GUIDE BAR

See Figure 40.

CAUTION:

Makesurethechainhasstoppedandthebat-

terypackhasbeenremovedbeforeyoudoany

workonthesawtoavoidaccidentalstartingor

contactwiththemovingchainthatmayresult

in injury.

Propermaintenancewillmaximizetheusefullife

oftheguidebar.

Each day of use:

Cleanthebarandcheckforwearanddamage.

Featheringorburringofthebarrailsisanormal

processof bar wear, but such faults should be

smoothedwithafileassoonastheyoccur.

Each week of use:

Reversetheguidebaronthesawtodistribute

thewear.

Lubricatethesocketattheendoftheguidebar

usingagreasesyringeinthelubricatinghole.

Turntheguidebarandcheckthatthelubrication

holesandchaingroovearefreefromimpurities.

A bar with any of the following faults should be

replaced immediately:

FIG. 40

FIG. 41

Loading...

Loading...