27 – English

damagearepresentintheareasindicated,havethe

drivesprocketreplacedbyaHARTServicedealer.

HOW TO SHARPEN THE CUTTERS

See Figures 33 - 34.

Becarefultofileallcutterstothespecifiedangles

andto the same length, as fastcutting can be

obtainedonlywhenallcuttersareuniform.

WARNING:

Thesawchainisverysharp,alwayswearpro-

tectivegloveswhen performingmaintenance

tothechaintopreventseriouspersonalinjury.

Properlytensionthechainpriortosharpening.

Refer to Adjusting the Chain Tension earlier in

thismanual.Doallofyourfilingatthemid-point

ofthebar.

Usea5/32in.diameterroundfileandholder.

Keepthefilelevelwiththetopplateofthetooth.

Donotletthefilediporrock.

Usinglightbutfirmpressure,stroketowardsthe

frontcornerofthetooth.

Liftfileawayfromthesteeloneachreturnstroke.

Putafewfirmstrokesoneverytooth.Fileallleft

handcuttersinonedirection.Thenmovetothe

othersideandfiletherighthandcuttersinthe

oppositedirection.Occasionallyremovefilings

fromthefilewithawirebrush.

WARNING:

Improperchainsharpeningincreasesthepo-

tentialofkickback,whichcanresultinserious

personalinjury.

WARNING:

Failuretoreplaceorrepairdamagedchaincan

cause serious injury.

NOTICE:

Adullorimproperlysharpenedchaincancause

excessiveenginespeedduringcutting,which

mayresultinsevereenginedamage.

MAINTENANCE

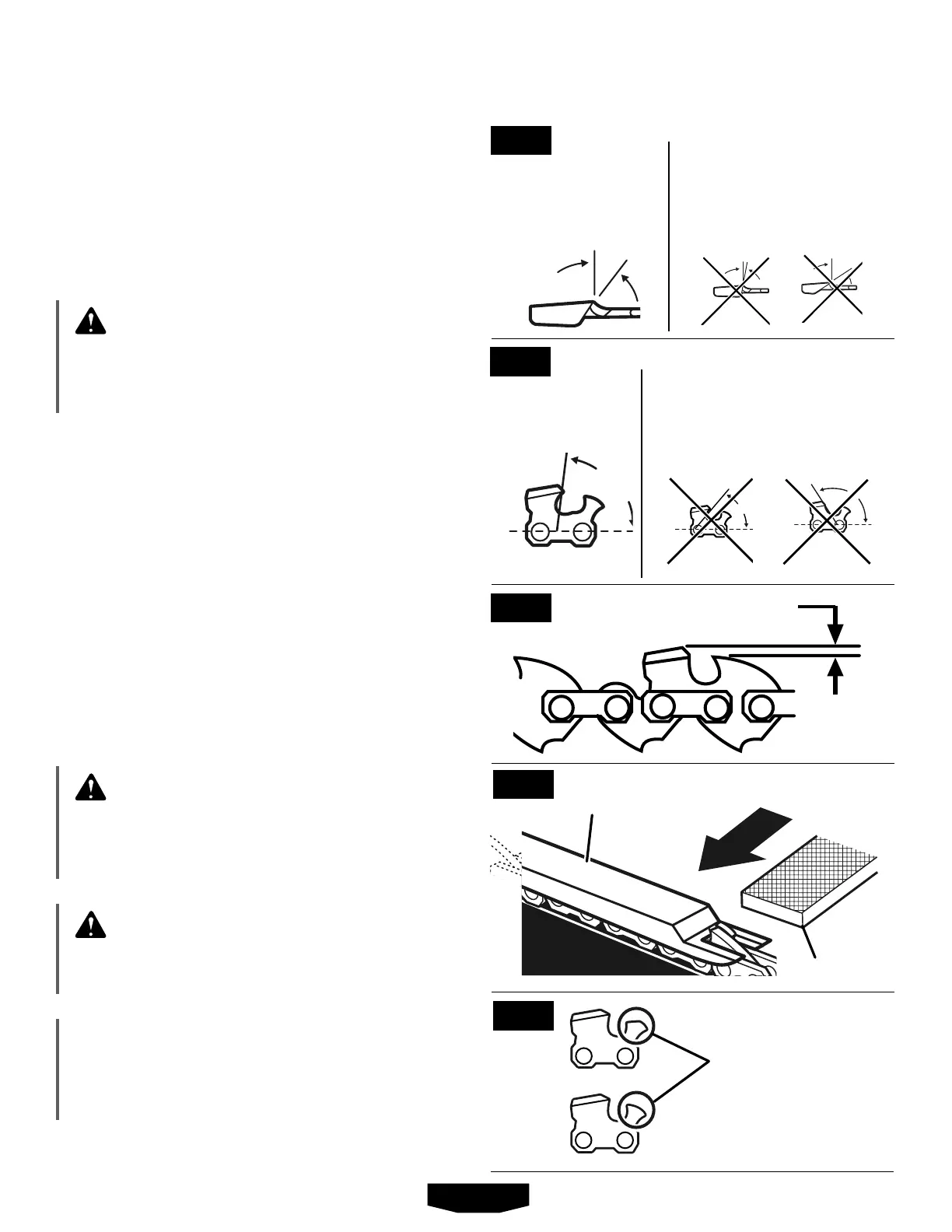

INCORRECT TOP PLATE FILING

ANGLE

MORE

THAN 30°

LESS

THAN 30°

30°

CORRECT TOP PLATE

FILING ANGLE

INCORRECT SIDE PLATE

FILING ANGLE

BACKWARD

SLOPE

HOOK

80°

CORRECT SIDE

PLATE FILING

ANGLE

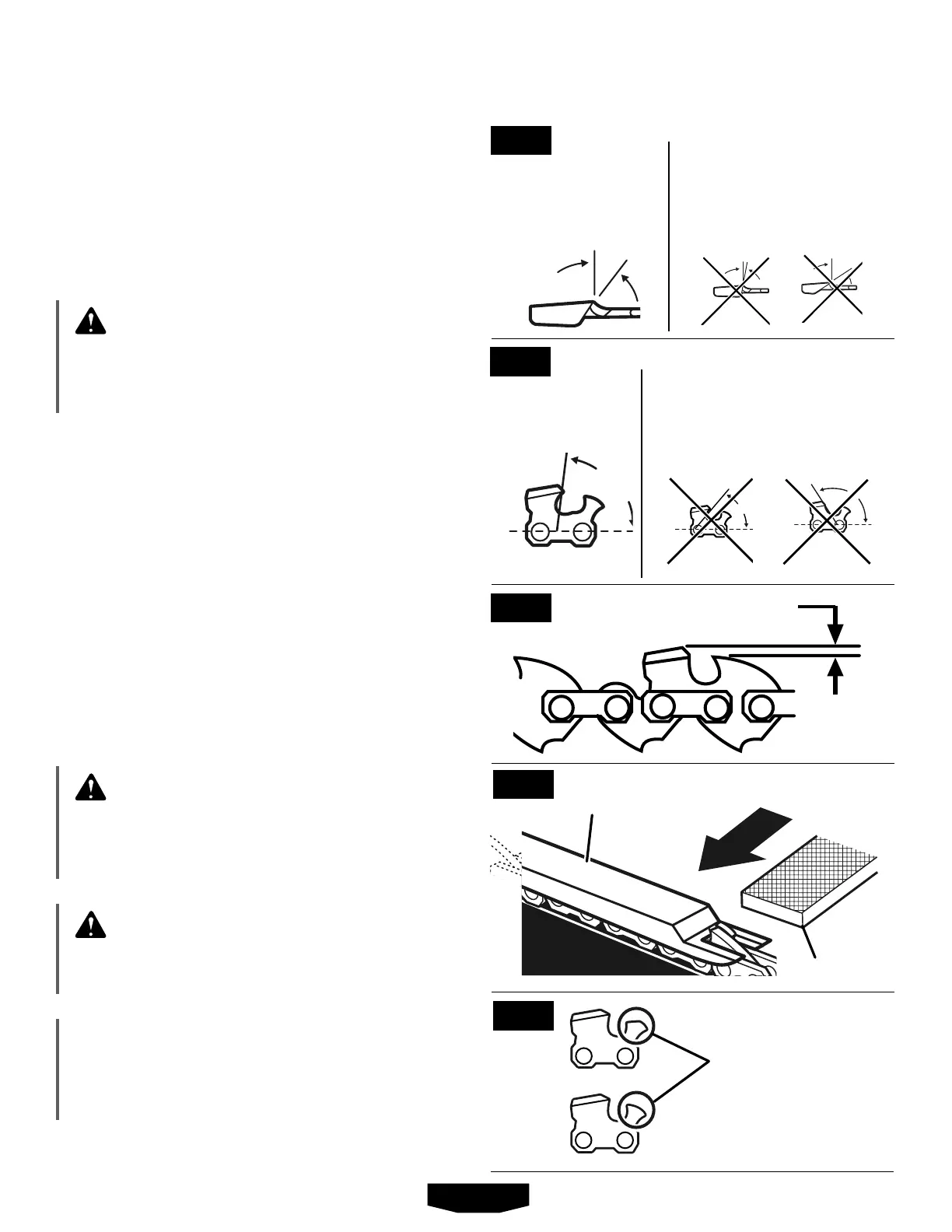

RAKER CLEARANCE

.025 in.

Fig.37

FLAT FILE

DEPTH GAUGE JOINTER

RESTORE ORIGINAL

SHAPE BY ROUNDING

THE FRONT

FIG. 35

FIG. 36

FIG. 37

FIG. 38

FIG. 39

Loading...

Loading...