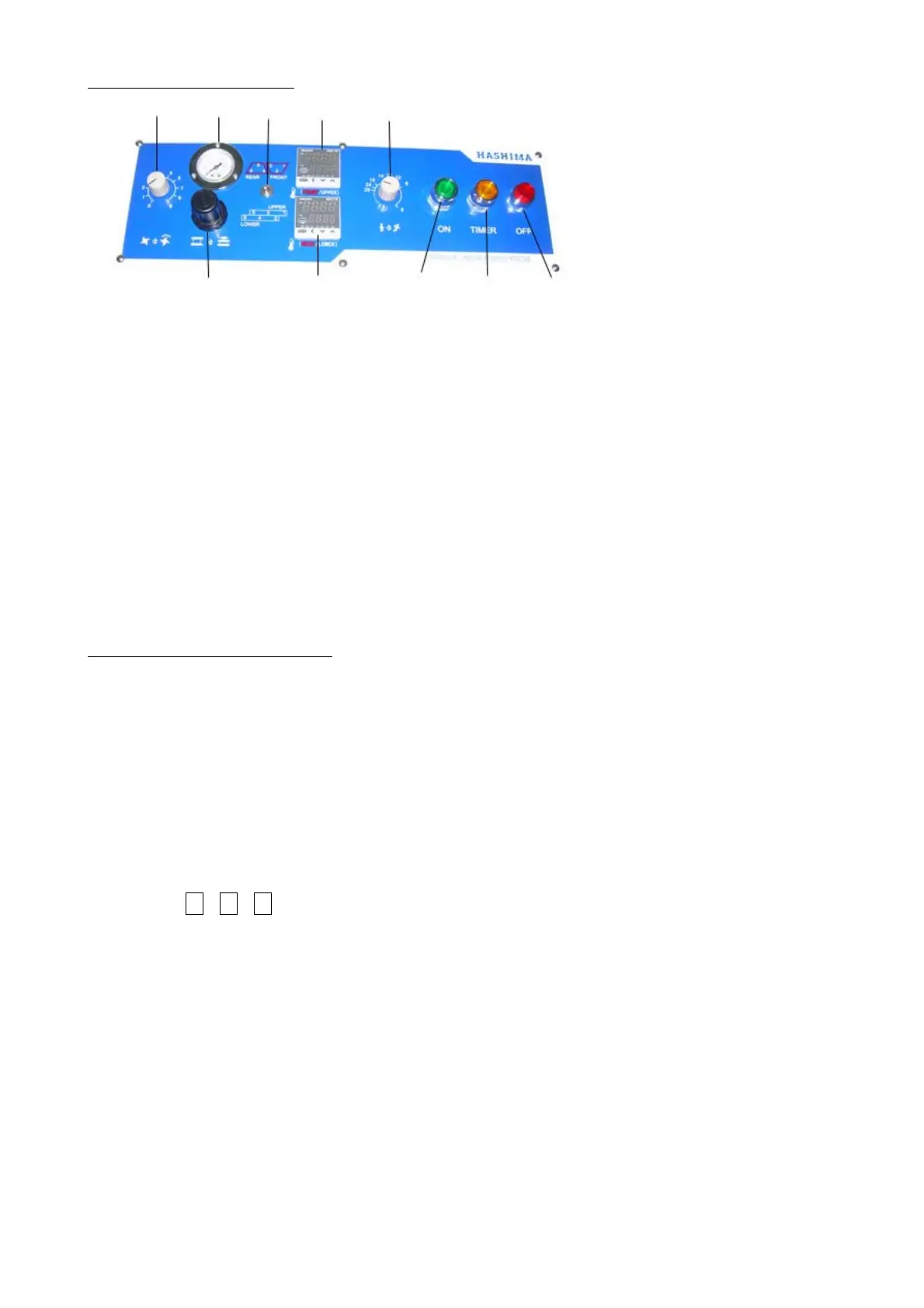

4. OPERATION PANEL

1.POWER SWITCH When turns on switch, switch will light up.

2.TIMER SWITCH This timer is to keep the machine operating, after completion of

the work until the belts are cooled to certain temperature in

order to insure a long belt life.

3.STOP SWITCH When push the switch, machine will stop.

4.SPEED CONTROL KNOB It is control knob for fusing time.

5.THERMOSTAT Heater control for upper or front part

6.THERMOSTAT Heater control for lower or rear part

7.HEATER SELECT SWITCH The temperature of front and rear heaters can be controlled by

pushing up the snap switch, and by pushing down it, the

temperature of upper and lower heaters can be controlled.

8.PRESSURE METER 0.1Mpa to 0.4Mpa(MAX)

9.PRESSURE CONTROL KNOB

10.ROTARY STRIP OFF SPEED CONTROLLER

5. OPERATION INSTRUCTIONS

○ Make sure, prior to use, whether or not there is a container contained flashing,

combustible, ignitable and water on or around the machine, and also make sure that there

is no any object which may involve into feeding or exit side of the machine. Remove them

when you’ve found them.

○ The personnel should pay attention to his clothes not to be caught in the machine.

1. Turn on the circuit breaker switch on the right under the wiring box of the machine.

2. Turn on the power switch (push button switch)

※ The push button of the switch will light up.

※ The motor runs simultaneously.

3. Set the heater selector switch on the front/rear heater.

※ When using upper/lower heaters, turn the snap switch downward.

4. Set the < > ∧ button of thermostat, and set the front/rear or the upper/lower

heaters to the proper temperature.

5. Turn the dial of the fusing timer, and set to the proper fusing time.

※ The fusing time ranges from 5 sec, minimum to 35sec. Maximum.

6. Turn the pressure knob on the operation panel, and set to the proper pressure level.

Usually, enough pressure for fusing is given at the position 0.1~0.3Mpa. The pressure

is adjustable within a range from 0Mpa minimum to 4.0Mpa maximum.

7. If the machine is equipped with the strip-off device, turn the dial of the strip-off speed

controller to set the position to a little faster than the running speed of the Teflon

belt.

8. Please push the timer switch After completion of work. The actual temperature of the

thermostat will go down. When the actual temperature of the thermostat goes down to

90℃,the power will automatically turn off.

9. When the time switch has terminated, set the power source breaker to OFF.

From the Library of Superior Sewing Machine & Supply LLC

Loading...

Loading...