9

CA80

SG INSTALLATION

7 SG INSTALLATION

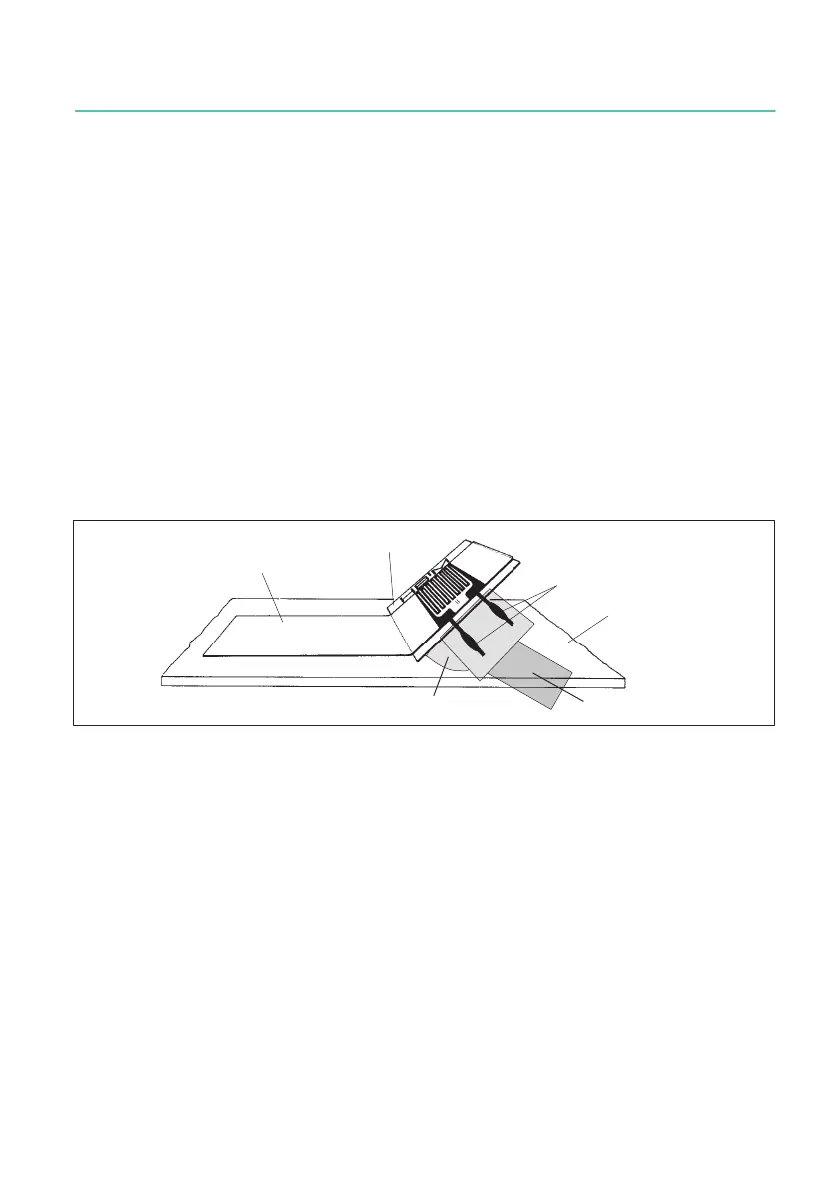

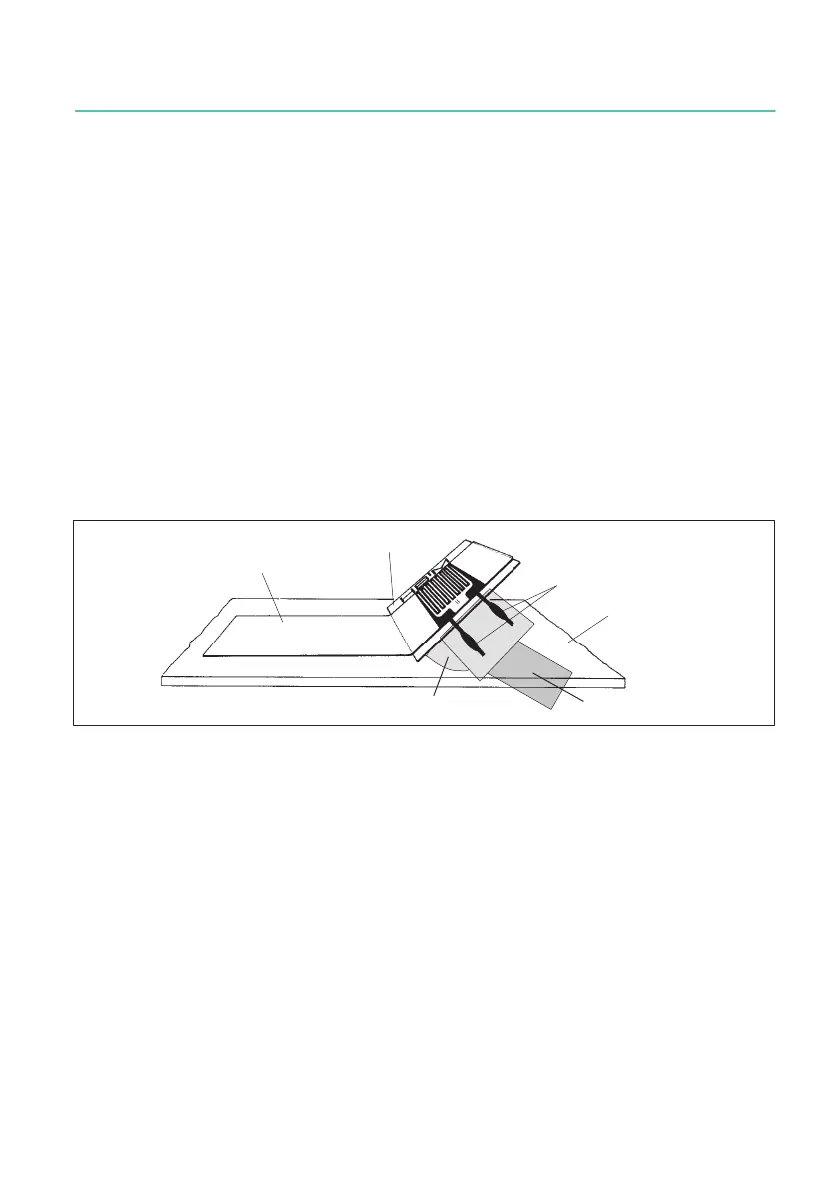

u To prepare for installation, prepare a piece of the supplied fluoropolymer tape and a

section of the fluoropolymer strip.

7.1 Applying the adhesive

u The adhesive must be at room temperature before you open the bottle to prevent

moisture getting into the adhesive.

u Apply a drop of the adhesive to the workpiece.

u Use the piece of the fluoropolymer strip that you have just prepared to carefully

spread the drop of adhesive without applying any pressure and without touching the

measurement object. This may otherwise lead to partial hardening of the adhesive.

u Next, immediately fold the strain gage down onto the layer of adhesive. You must use

the supplied fluoropolymer tape to prevent adhesive from getting onto other objects

(Caution: Also sticks to skin).

u Applying even pressure with your thumb, press the SG (covered by the piece of fluo

ropolymer tape) onto the workpiece for approx. 1 minute.

Adhesive tape

SG

Installation area

Fluoropolymer strip

Adhesive

Solder terminals

Fig. 7.1 Spreading the adhesive onto the application area

7.2 Curing

The adhesive cures within several minutes at a relative humidity of approx. 65%. At lower

humidities, initial strength will be reached after a correspondingly longer waiting time.

u Only remove the adhesive tape from the SG after the adhesive has reached a

sufficient initial strength. The excess adhesive on and around the SG should be fully

dry.

u Carefully remove the adhesive tape at a low angle - starting from the SG - towards the

outside to reduce the danger of pulling off the SG as the adhesive will not be fully

cured yet.

Under unfavorable ambient conditions, you can use the accelerator BCY01 to reduce the

curing time. Treat one of the two surfaces to be bonded with BCY01 and the adhesive will

cure immediately.

Loading...

Loading...