INSTALLATION INSTRUCTIONS Fan Coils: FEM4X, FEM4P, REM4X

496 01 5503 00 7

Specifications are subject to change without notice.

E. MANUFACTURED HOUSING AND MOBILE HOME

APPLICATIONS

1. Fan coil unit must be secured to the structure using

field−supplied hardware.

2. Allow a minimum of 24 inches (610mm) clearance

from access panels.

3. Recommended method of securing for typical

applications:

a. If fan coil is away from wall, attach pipe strap to top

of fan coil using No. 10 self tapping screws. Angle

strap down and away from back of fan coil, remove

all slack, and fasten to wall stud of structure using

5/16” lag screws. Typical both sides of fan coil.

b. If fan coil is against wall, secure fan coil to wall stud

using 1/8” (3mm) wide right−angle brackets. Attach

brackets to fan coil using No. 10 self tapping screws

and to wall stud using 5/16” lag screws (refer to

Figure 7).

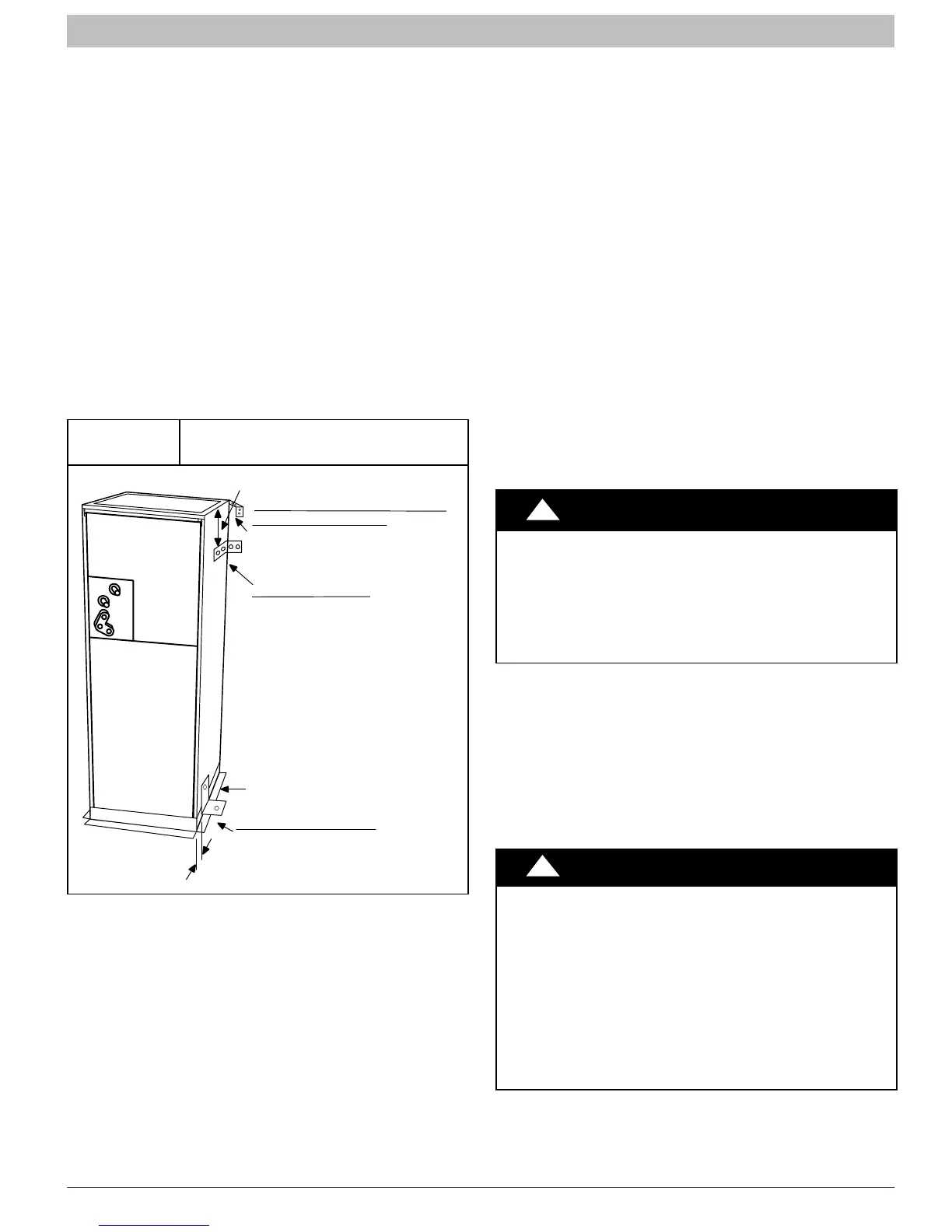

Figure 7

Mobile Home or Manufactured

Housing Applications

(TYPICAL BOTH SIDES)

OR

DOWN FLOW

BASE KIT

UNIT AGAINST WALL

1/8” (3mm) INCH THICK ANGLE

MOUNTING BRACKET

(TYPICAL BOTH SIDES)

SECURE FAN COIL TO STRUCTURE

UNIT AWAY FROM WALL

PIPE STRAP

SECURE UNIT TO FLOOR

ANGLE BRACKET OR PIPE STRAP

4” (102mm) MAX

4” (102mm) MAX

AIR DUCTS

Connect supply−air duct over the outside of 3/4” flanges

provided on supply−air opening. Secure duct to flange using

proper fasteners for type of duct used, and seal duct−to−unit

joint.

It is a recommendation, but not a requirement, to use flexible

connections between ductwork and unit to prevent

transmission of vibration. When electric heater is installed,

use heat−resistant material for flexible connector between

duct work and unit at discharge connection. Duct work

passing through unconditioned space must be insulated and

covered with vapor barrier.

Duct Work Acoustical Treatment

Metal duct systems that do not have a 90 degree elbow and

10 feet of main duct before first branch takeoff may require

internal acoustical insulation lining. As an alternative,

fibrous duct work may be used if constructed and installed in

accordance with the latest edition of SMACNA construction

standard on fibrous glass ducts. Both acoustical lining and

fibrous duct work shall comply with National Fire Protection

Association as tested by UL Standard 181 for Class 1 air

ducts.

ELECTRICAL CONNECTIONS

FEM4X, FEM4P, and REM4X Fan Coil models do not have a

printed circuit board (PCB), they have a low voltage circuit

protective fuse (3 amp) inline on the wire harness. Speed

selections are made at the fan motor with the Blue wire. The

motor is pre−programmed with the time−delay circuit on some

of the speed taps. (See Page 9, Section D)

Before proceeding with electrical connections, make certain

that supply voltage, frequency, phase, and circuit ampacity are

as specified on the unit rating plate. See unit wiring label for

proper field high and low voltage wiring.

!

WARNING

ELECTRICAL SHOCK or UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal

injury, death, and/or unit damage.

If a disconnect switch is to be mounted on unit, select a

location where drill and fasteners will not contact

electrical or refrigeration components.

Make all electrical connections in accordance with the NEC

and any local codes or ordinances that may apply. Use

copper wire only. The unit must have a separate branch

electric circuit with a field−supplied disconnect switch

located within sight of and readily accessible from the unit.

NOTE: When a pull−out type disconnect is removed from

the unit, only the Load side of the circuit is de−energized.

The Line side remains live until the main (remote)

disconnect is turned off.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Turn off the main (remote) disconnect device before

working on incoming (field) wiring.

Incoming (field) wires on the line side of the disconnect

found in the fan coil unit remain live, even when the

pull−out is removed. Service and maintenance to

incoming (field) wiring cannot be performed until the main

disconnect switch (remote to the unit) is turned off.

Loading...

Loading...