INSTALLATION INSTRUCTIONS R-410A, Two-Stage Split System Air Conditioner

421 01 6001 00 11

TROUBLESHOOTING

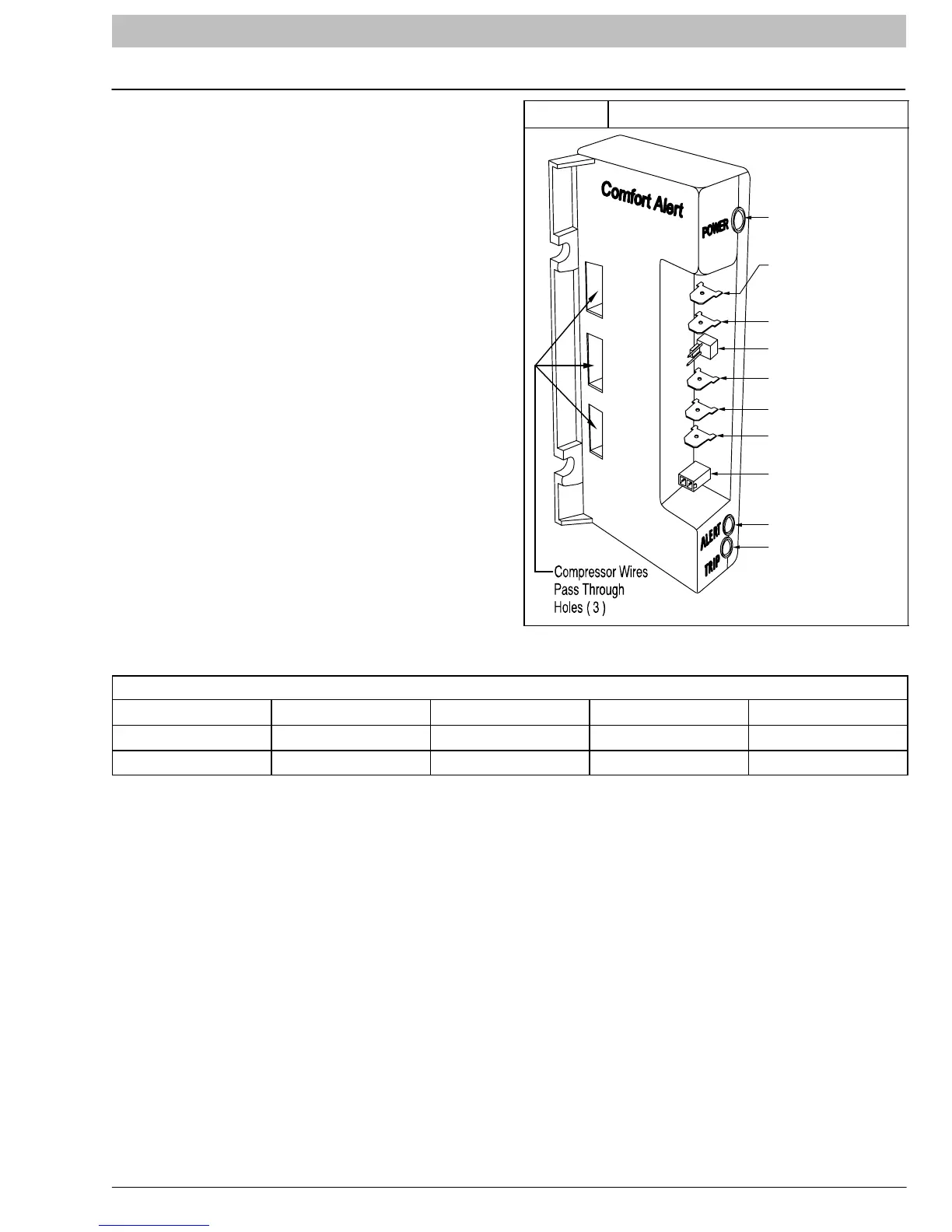

Models are factory equipped with the Comfort Alert

UltraTech Diagnostics device (refer to Figure 11) in the

control box. Comfort Alert UltraTech provides

compressor staging from low to high and high to low

capacity. Comfort Alert UltraTech provides

around-the-clock monitoring for common electrical

problems, compressor defects, and broad system faults.

If trouble is detected, an alert code is displayed with a

flashing LED indicator. Alert codes are listed in Figure 12.

The device is factory wired and requires no

modification. Low voltage lead wires are provided in the

control box for connection to thermostat wires (use wire

nuts).

The Comfort Alert UltraTech must be powered to properly

stage compressor to high capacity. Energizing the Y (Y1)

terminal operates the compressor in low stage. Both the

Y (Y1) and Y2 terminals must be energized for

high-stage operation.

The Comfort Alert UltraTech device operates by

monitoring the compressor power leads and the

thermostat demand signals Y (Y1) and Y2 terminals. It

draws constant 24 VAC power at the R and C terminals.

When the compressor is operating in low stage (Y or Y1),

the 24v DC compressor solenoid coil is de-energized.

When the compressor is operating in high stage (Y or Y1

and Y2), the 24v DC solenoid coil is energized. The 24v

DC plug that is connected to the compressor does NOT

have an internal rectifier. DO NOT INSTALL A PLUG

WITH INTERNAL RECTIFIER.

Figure 11

Comfort Alertt UltraTecht Diagnostics

Y2

Y

L

R

C

R

C

S

“Power” LED

Thermostat Demand

1

st

Stage Compressor

Data Port

Thermostat Signal

24 VAC HOT

24 VAC Common

DC Compressor

Solenoid

“Alert” LED

“Trip” LED

Thermostat Demand

2

nd

Stage Compressor

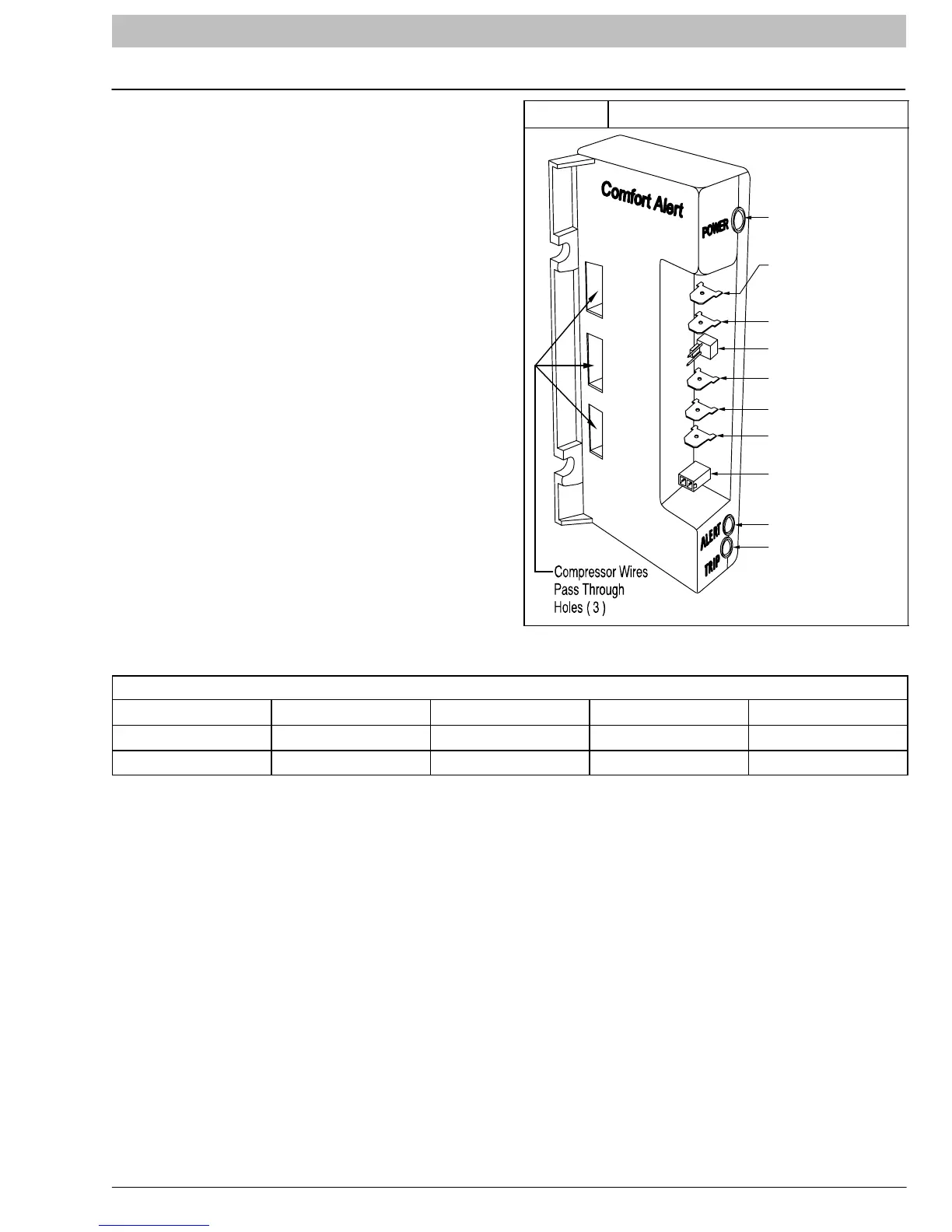

Two-Stage Compressor Resistance (winding resistance) at 70°F +/- 20°F

Winding *4A624 *4A836 *4A648 *4A660

Start (S-C) 1.40 1.29 1.52 0.60

Run (R-C) 1.32 0.89 0.64 0.49

NOTE: The rectifier for the DC solenoid is contained

within the Comfort Alert UltraTech device. The plug at the

compressor solenoid is an ordinary 2-wire plug. Never

use a plug with internal rectifier with this system.

NOTE: The DC compressor solenoid plug that connects

to the Comfort Alert UltraTech is polar dependent and

should only be connected with the tabs aligned.

Unloader Test Procedure with Comfort Alertt Module

The unloader is the compressor internal mechanism,

controlled by the DC solenoid, that modulates between

high and low stage.

If it is suspected that the unloader is not working, the

following methods may be used to verify operation.

1. Operate the system and measure compressor

amperage. Cycle the unloader on and off at ten

plus second intervals by applying and removing Y2

voltage to the module. Wait five seconds after

power is applied to Y2 before taking a reading. The

compressor amperage should go up or down at

least 25 percent.

2. If step one does not give the expected results,

remove the solenoid plug from the compressor

and, with the unit running and the thermostat

calling for Y2 to be energized, test the voltage

output at the plug with a DC voltmeter.

The reading here should be 4 to 18 volts. If NOT,

unplug the harness from the module and check

voltage at the “DC Sol” pins of the module. The

module will not power the unloader solenoid if the

compressor is not running or fault code 1 or 9 is

active.

3. If the correct DC voltage is at the control circuit

molded plug, measure the unloader coil

resistance. The resistance should be 32 to 60

ohms depending on compressor temperature. If

the coil resistance is infinity, much lower than 32

ohms, or is grounded, the compressor must be

replaced.

Loading...

Loading...