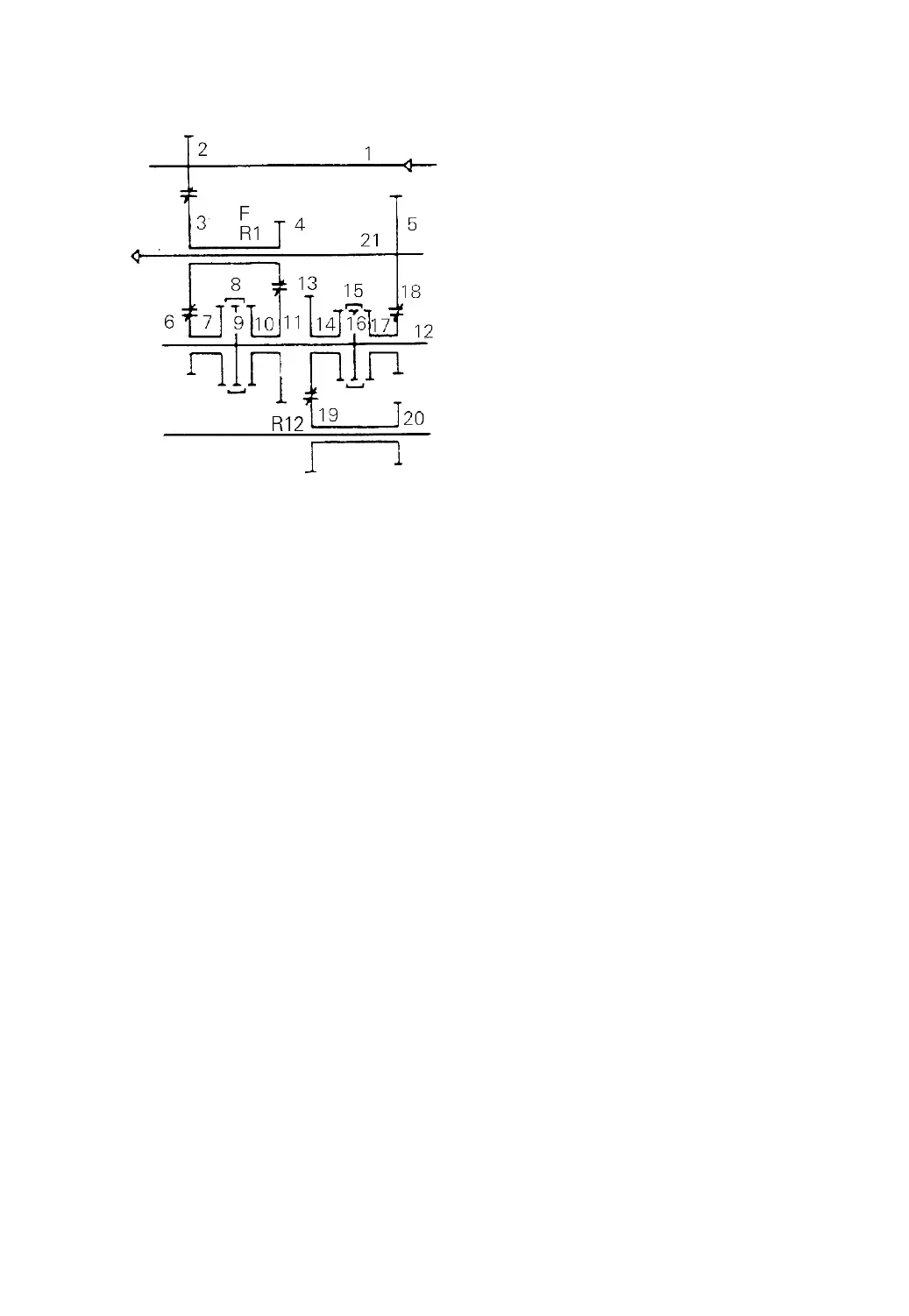

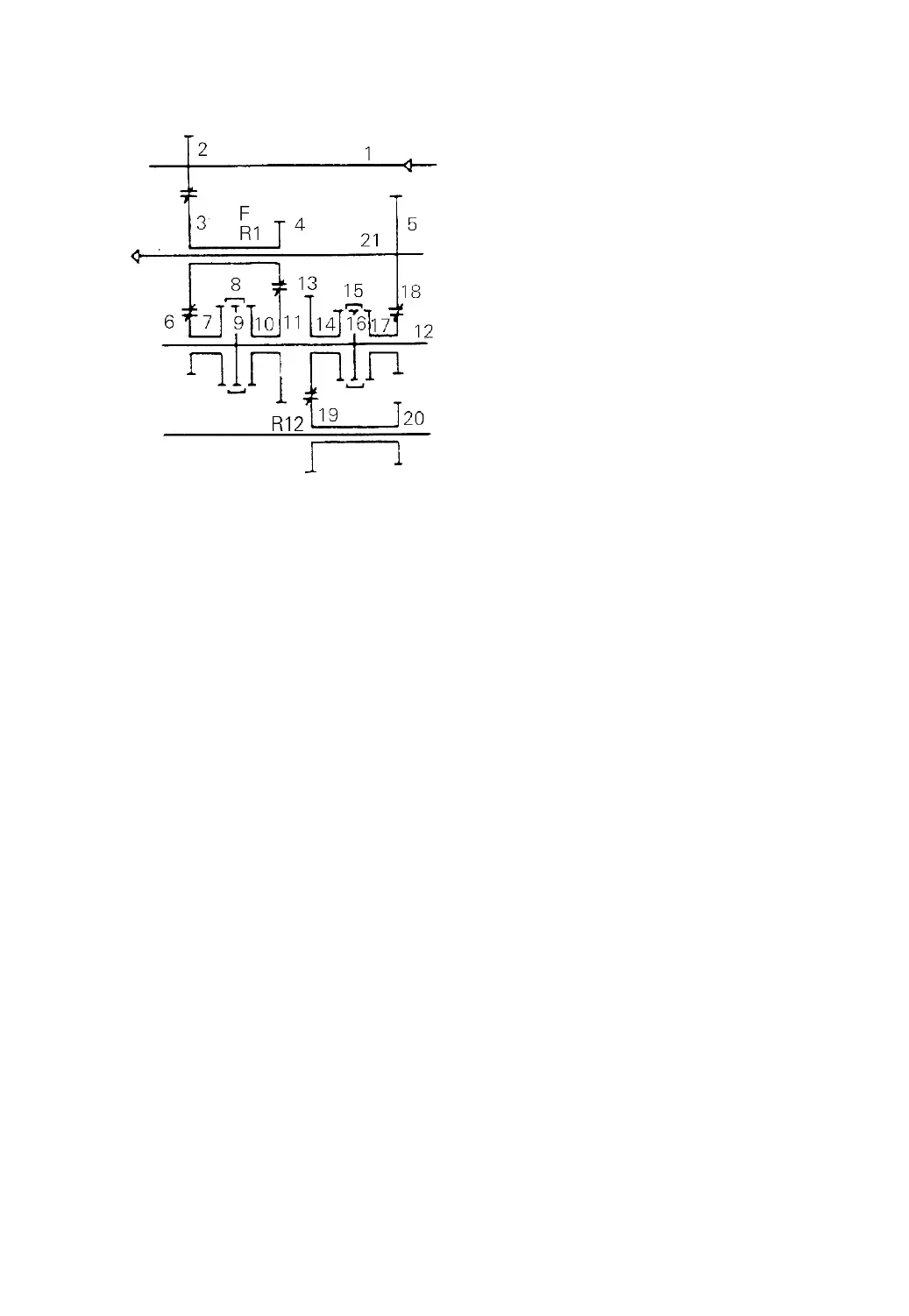

Fig. 3-11

In neutral position —

The power from the driving shaft (1) is transmitted through the input gear, the

cluster gear (3) & (4) to the high speed gear (6) or low speed gear (11). Due to the

mesh sleeve is in the neutral position, the main shaft, output gear and output shaft are

not rotated so the power is not transmitted to the high speed or low speed gear,

Gear shifting —

When the shifting lever is operated, the shift fork moves the mesh sleeve to

allow relative gears to mesh through the synchromesh mechanism. Power is

transmitted in the following order:

Driving shaft-Input gear-Cluster gear-High (or low) speed gear-Synchromesh

mechanism-Main shaft-Synchromesh mechanism-Reverse (or forward) gear-Output

gear- Output shaft.

Power flow in forward 1st speed gear position:

1-2-3-4-11-10-8-9-12-16-15-17-18-5-21

Power flow in forward 2nd speed gear position:

1-2-3-6-7-8-9-12-16-15-17-18-5-21

Power flow in reverse 1st speed gear position:

Power flow

Driving shaft

Output shaft

(1) Driving shaft

(2) Input gear

(3) Cluster gear

(4) Cluster gear

(5) Output gear

(6) High speed gear

(7) Synchronizing cone

(8) Mesh sleeve

(9) Clutch hub

(10) Synchronizing cone

(11) Low speed gear

(12) Main shaft

(13) Reverse gear

(14) Synchronizing cone

(15) Mesh sleeve

(16) Clutch hub

(17) Synchronizing cone

(18) Forward gear

(19) Idler shaft

(20) Idler gear

(21) Output shaft

-24-

Loading...

Loading...