Introduction

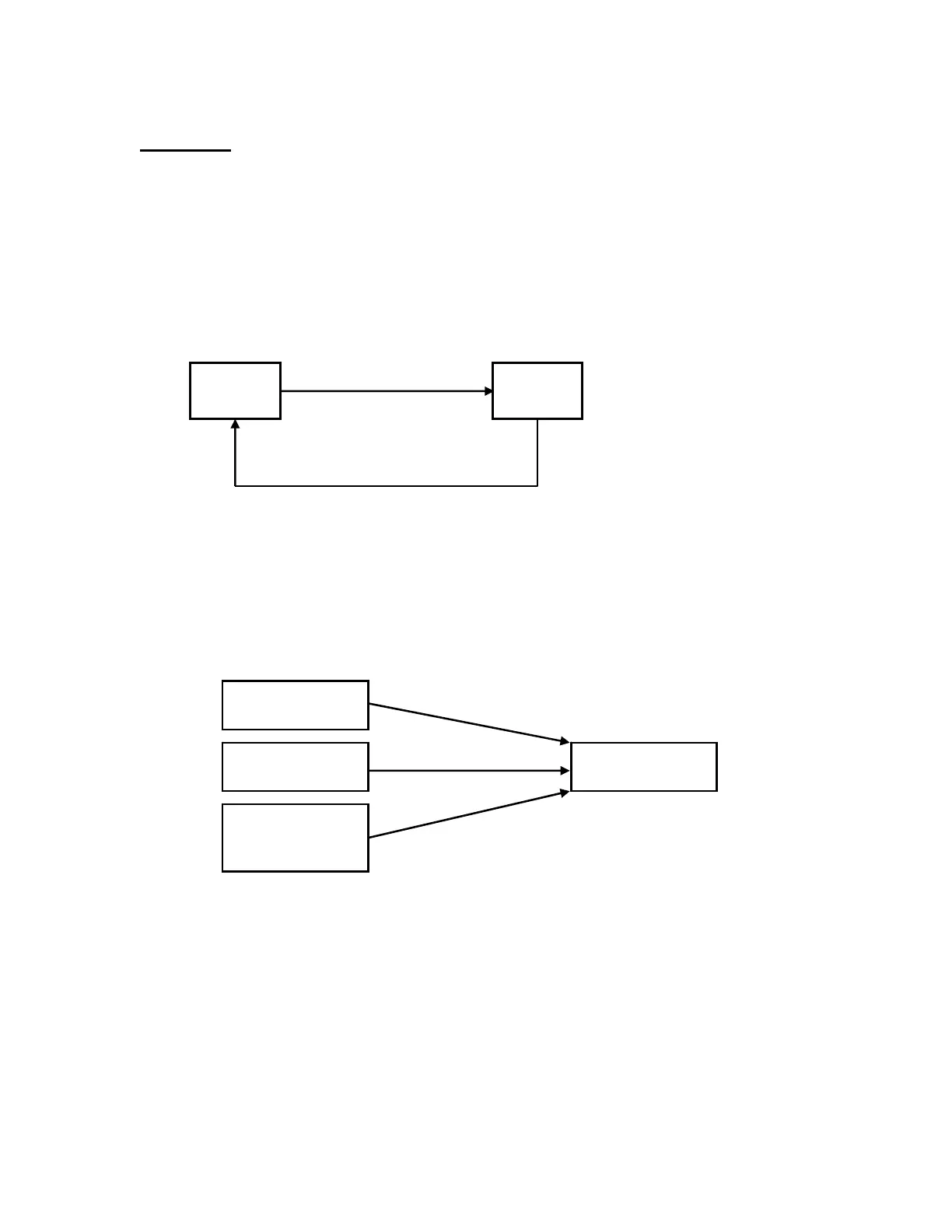

The TMG-1200 detects the “Front Dead Center” (FDC) positions of the cold former using a

proximity sensor and sends a fault signal to the output when the difference between FDC

positions at each stroke exceeds the preset range. The TMG-1200 will send a fault signal to the

output when the revolutions (rpm) of the cold header or cold former fall below the preset range

when slowdown detection is set to On.

Fault detection of FDC position is performed in two modes - Adaptive (mean value) comparison

and Trend (absolute value) comparison. For each of these modes, it is possible to preset the

operating range. Slowdown detection can be set in units of 1% in the range of –5% to –49%.

Header

Former

Sensor Signal

Header

Former

Monitoring by both Absolute

value and Mean value

Slowdown monitoring

Fault Detection Signal

(Stop Signal)

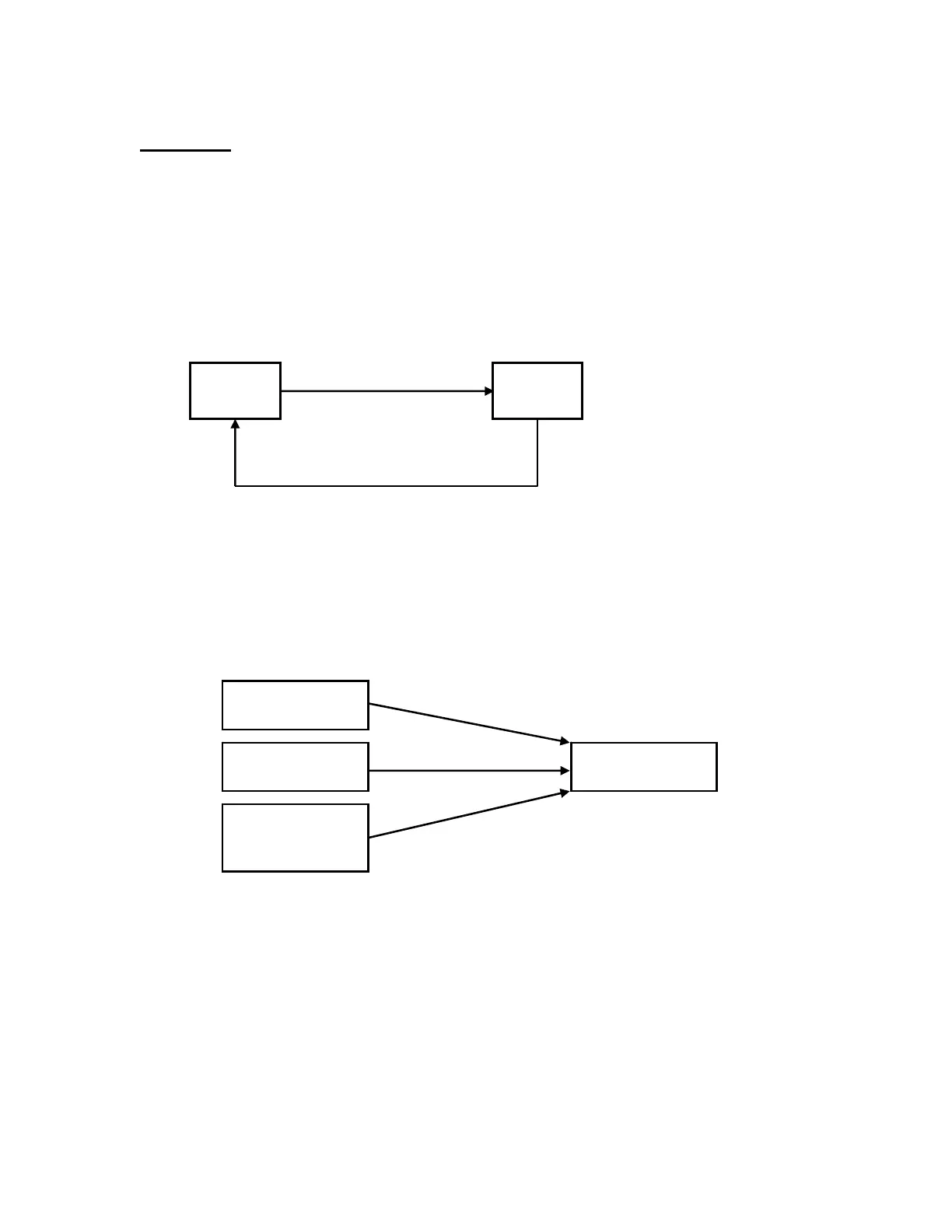

This device meets the requirements for the single, double and multi modes according to the types

of cold header and cold former.

The single mode is for single stroke, single die machines.

The double mode is for single stroke, double die machines.

The multi mode is a multi-slide or progressive header (Two sensors are necessary only in the

case of using the multi mode.) The TMG-1200 can be setup for operation in any of these modes.

Refer to the contents of Section “System Setting”.

One Stroke

One Die

One Stroke Two

Two Die

One Stroke

Two Die

Multi-Slide or

Progressive

Header

The device is factory set in the double mode. The set point setting and system setting are preset

at the factory. System can start at installation.

Page 2

TMG-1200 Instruction Manual

Loading...

Loading...