Page 5For technical questions, please call 1-888-866-5797.Item 57285

2. Install Right Work Rest (64) to the Right Work

Rest Support using Washer (54) and a Work

Rest Locking Knob (65). See below.

Work Rest (64)

Washer (54)

Locking

Knob (65)

Work Rest

Support

3. Install Left Work Rest Support (68) to the Left Inner

Wheel Guard (39). Use two Hex Bolts (72) and

two Flat Washers (73) to secure it in place.

4. Install Left Work Rest (69) to the Left

Work Rest Support using Washer (54)

and a Work Rest Locking Knob (65).

5. Adjust the Work Rests to within 1/16″ of the

Grinding Wheel. To adjust this distance,

loosen Bolts (72) and move Work Rests (64/69).

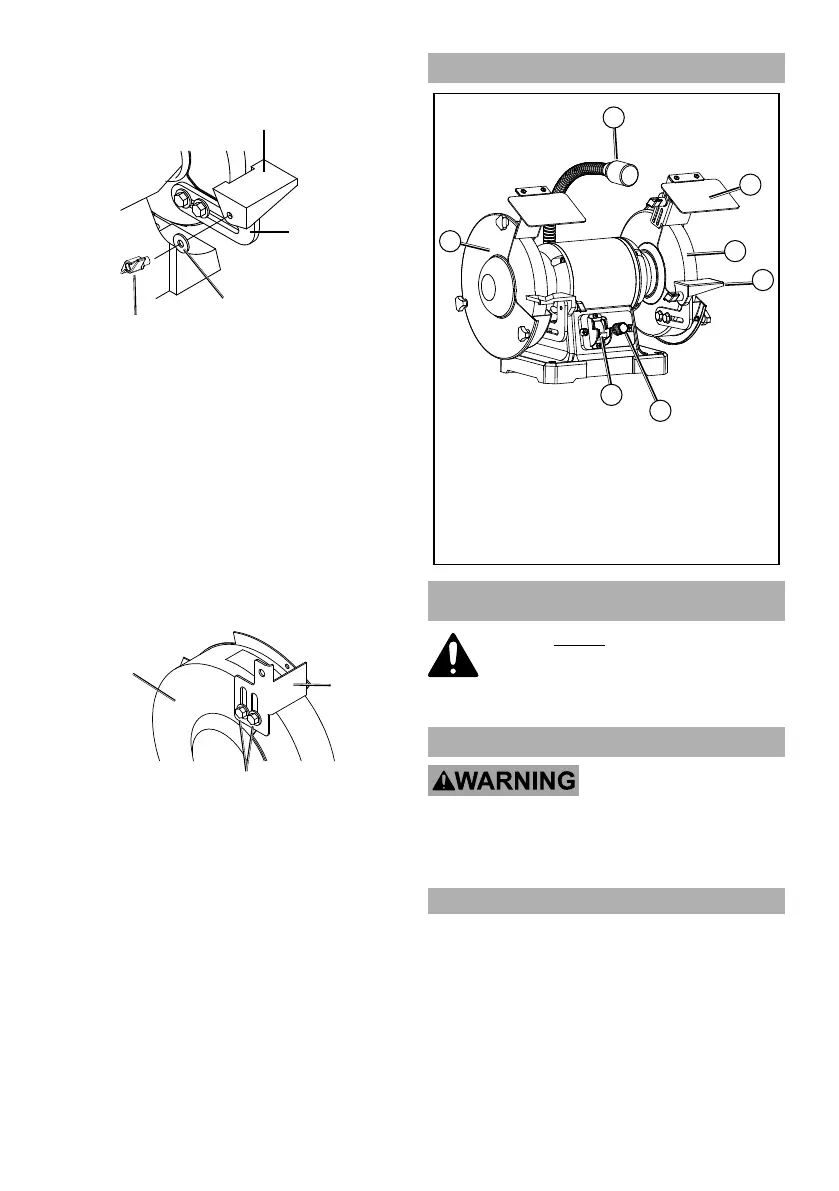

6. Attach a Spark Guard (60,67) to each

Inner Wheel Guard (39,62) using two

Bolts, Spring Washers, Flat Washers (59)

on each side. See below.

Spark

Guard (60)

Inner Wheel

Guard

Bolt (59)

7. Adjust each Spark Guard to within 1/16″

(0.0625″) of the Grinding Wheel (32,35)

and tighten each Bolt (59).

8. Attach Eye Shield (55) to the Right Spark Guard (60)

using a Neck Screw (61), Eye Shield Locking

Knob (53) and Flat Washer (54).

9. Attach the other Eye Shield (55) to the Left

Spark Guard (67) using a Neck Screw (61), Eye

Shield Locking Knob (53) and Flat Washer (54).

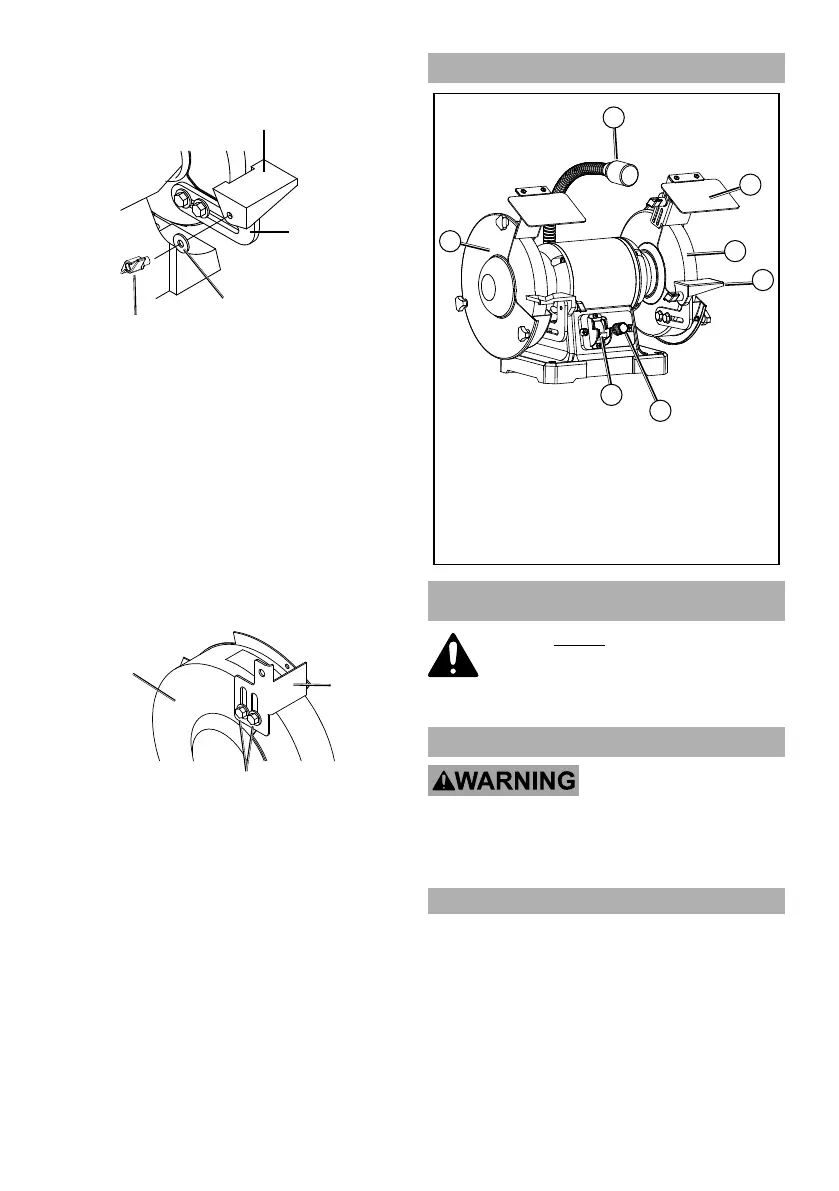

Functional Description

2

4

5

3

1

7

6

1. Wheel Cover

2. Eye Shield

3. Work Rest

4. Power Switch

5. Grinding Wheel

6. LED Light

7. Variable Speed Knob

OPERATION

Read the ENTIRE IMPORTANT

SAFETY INFORMATION section at the

beginning of this manual including

all text under subheadings therein

before set up or use of this product.

Tool Set Up

TO PREVENT SERIOUS INJURY FROM

ACCIDENTAL OPERATION:

Make sure that the Switch is in the OFF position and

unplug the tool from its electrical outlet before

performing any procedure in this section.

Replacing a Grinding Wheel

1. The Grinding Wheel MUST be:

• rated to at least 2,000 - 3,400 RPM.

• no larger than 8″ (203.2 mm) in diameter.

• fitted with a 5/8″ round arbor hole.

• 1″ thick.

• suitable for edge grinding, not surface grinding.

• dry and clean.

• proven undamaged by inspection and

by the ring-test explained below.

Loading...

Loading...