Page 7For technical questions, please call 1-888-866-5797.Item 58474

SETUP - BEFORE USE

Read the ENTIRE IMPORTANT SAFETY

INFORMATION section at the beginning of

this manual including all text under

subheadings therein before set up or use

.

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL

OPERATION: Release the Trigger and remove the

Battery Pack before performing any procedure in

this section.

Guide Bar Assembly

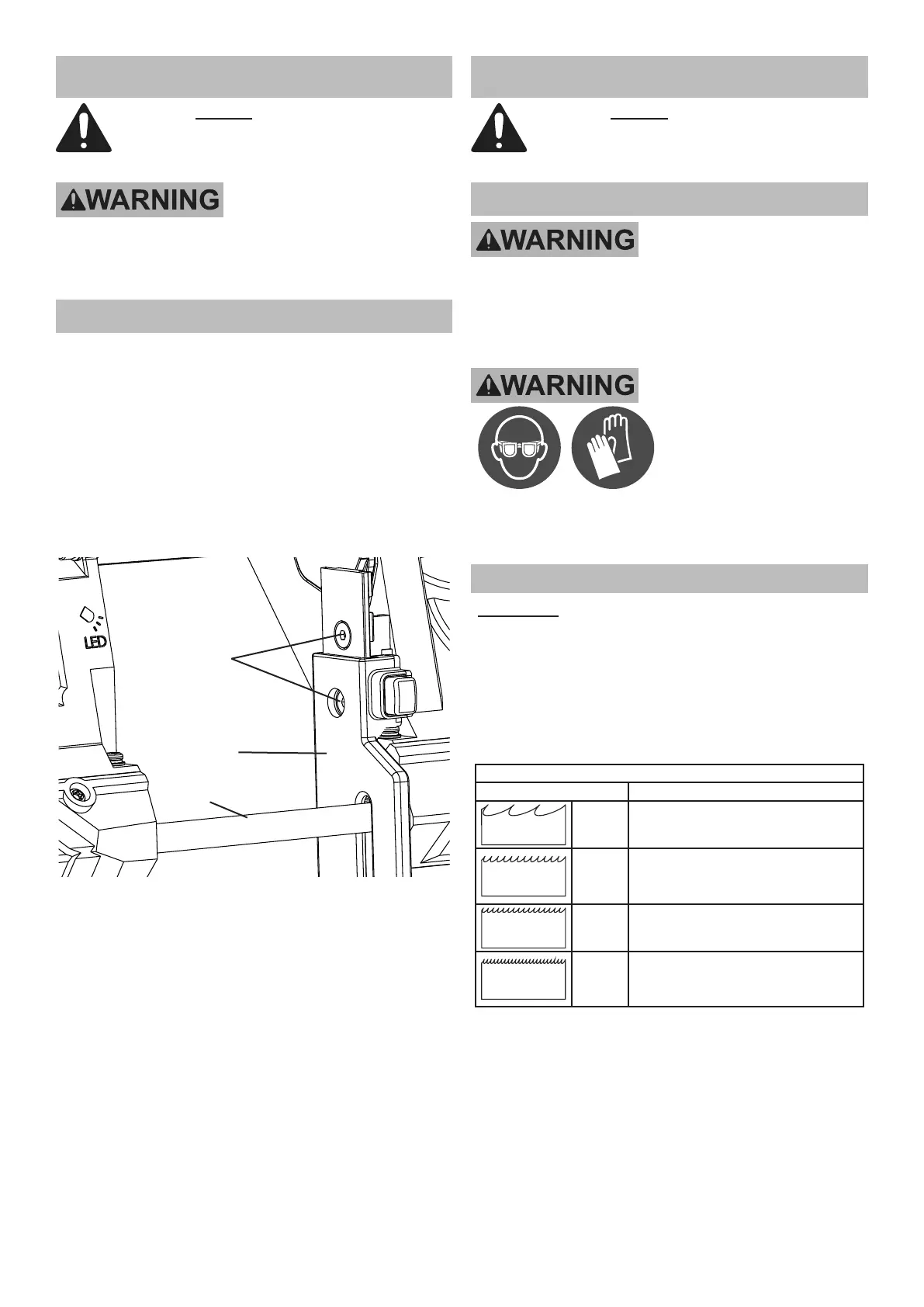

1. Assemble the Guide Bar to the

Band Saw before operation.

a. Remove the two Screws from the

frame of the Band Saw.

b. Position the Guide Bar around the Blade

as shown, aligning the mounting holes

on the Guide Bar with the tapped holes

on the frame of the Band Saw.

c. Secure the Guide Bar to the Band Saw

frame with the two Screws. See Figure A.

Guide

Bar

Screws

Blade

Figure A: Guide Bar Assembly

OPERATION

Read the ENTIRE IMPORTANT SAFETY

INFORMATION section at the beginning of

this manual including all text under

subheadings therein before set up or use

.

Tool Set Up

TO PREVENT SERIOUS INJURY FROM

ACCIDENTAL OPERATION:

Make sure that the Trigger is in the off-position

and remove its Battery Pack before

performing any procedure in this section.

TO PREVENT

SERIOUS INJURY:

Wear ANSI-approved

safety goggles, heavy-duty

work gloves, and heavy-

duty long-sleeved shirt or coat whenever

handling or working near the Blade.

The Blade can suddenly spring out during service.

Blade Selection

WARNING! TO PREVENT SERIOUS INJURY

FROM BLADE COMING LOOSE, ONLY USE

BLADES OF THE SPECIFIED SIZE.

Select the proper Blade according to the cutting

material and the diameter or size of the workpiece.

This Band Saw accepts 44-7/8″ x 1/2″ x .025″ Blades.

(Blade sold separately.)

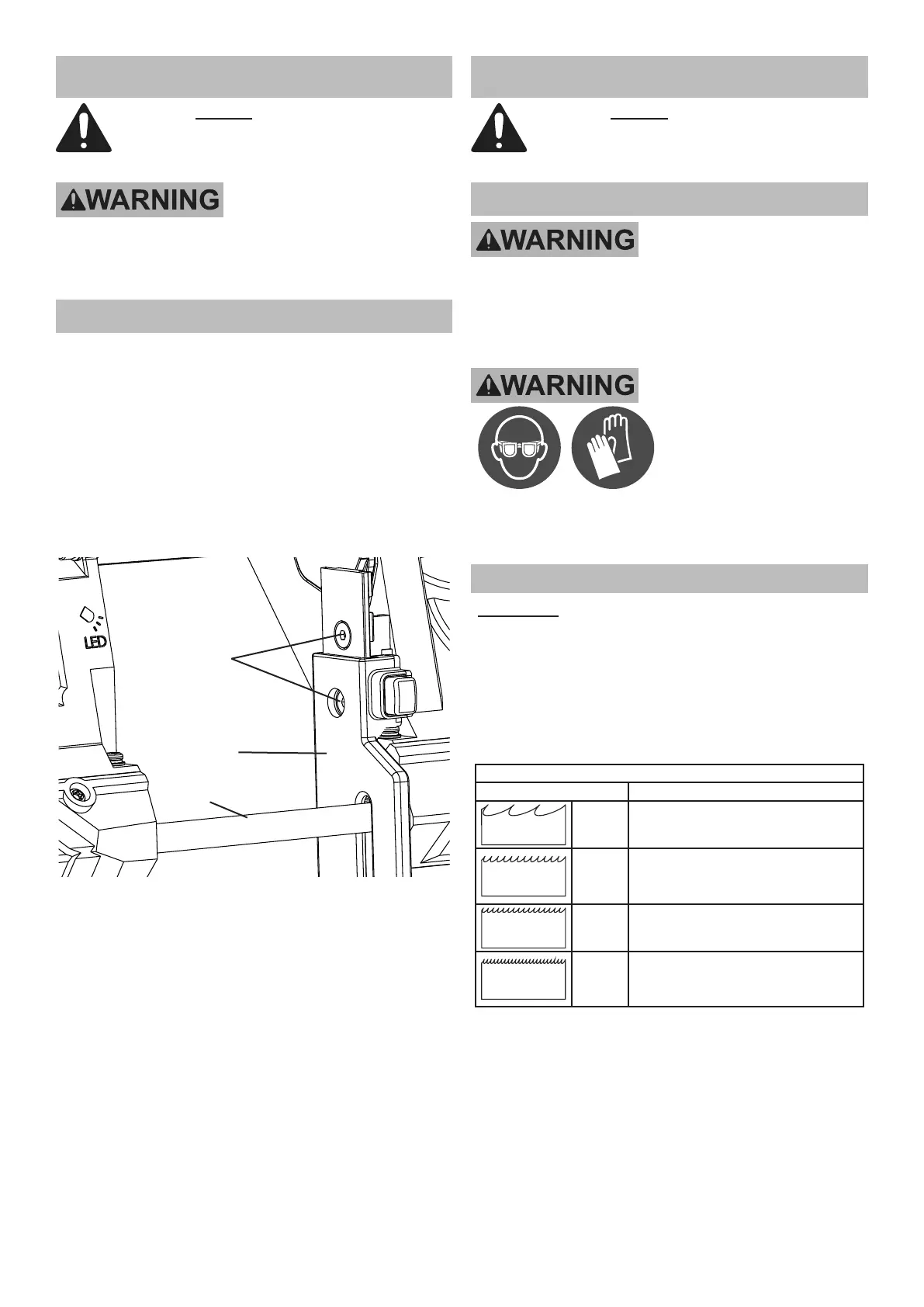

Common Blade Applications

Teeth Per Inch Use

3 - 4 Wood, resawing (ripping).

10 - 14

Stainless steel, angle iron,

pipe, tubing, plastic,

wood 1/4" or thicker.

14 - 18

Stainless steel, angle iron, pipe,

tubing, plastic, wood 1/8" to 1/4".

24

Stainless steel, angle iron,

pipe, tubing, plastic,

wood 1/8" or thinner.

Loading...

Loading...