Page 9For technical questions, please call 1-888-866-5797.Item 56790

Setting and Testing

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL

OPERATION: Make sure that the Trigger is in the off

position and unplug the tool from its electrical outlet

before performing any procedure in this section.

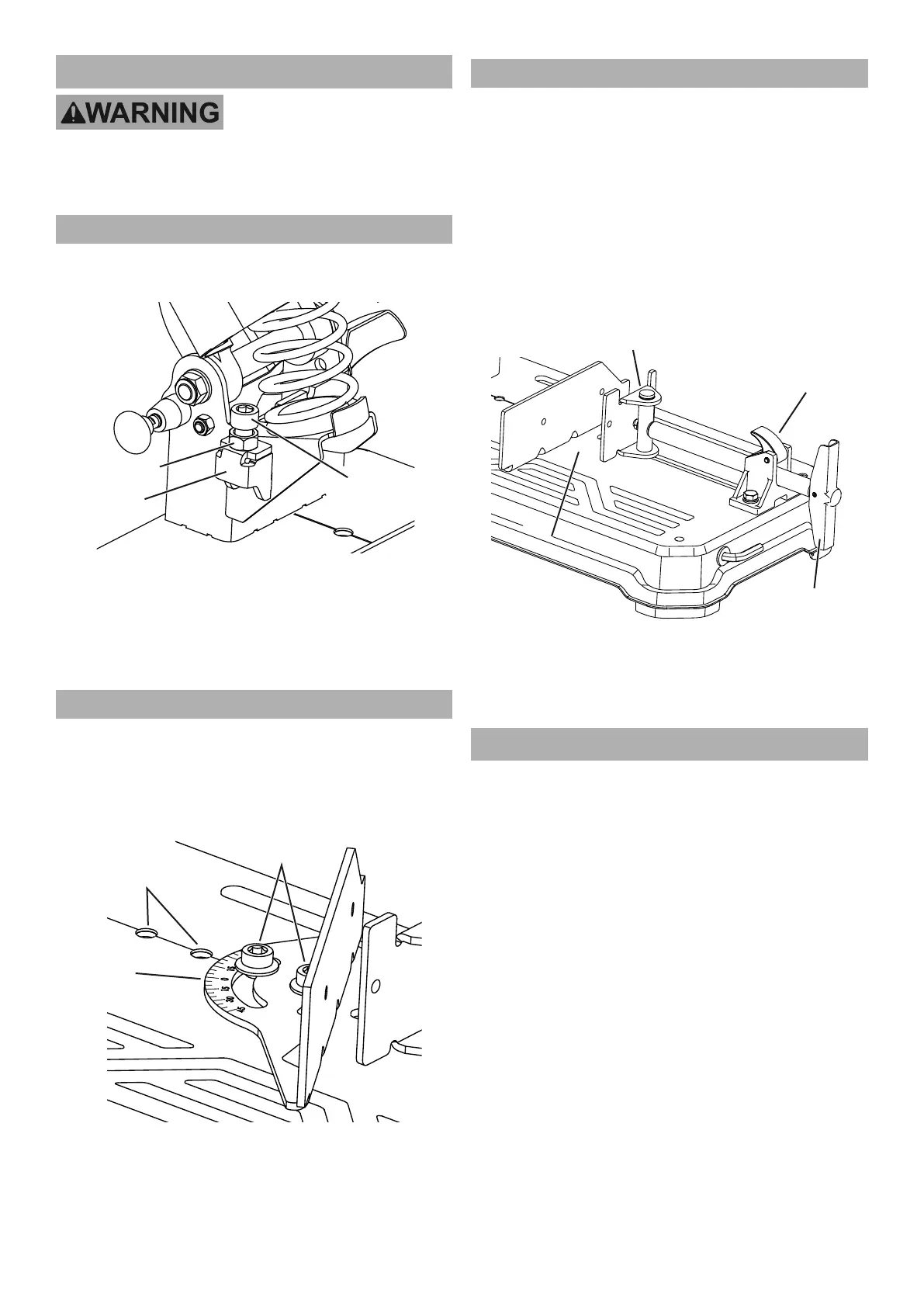

Using the Depth Stop

1. Loosen the Nut on the Depth Adjustment

Bolt shown in Figure D.

Depth Depth

Adjustment Adjustment

BoltBolt

Nut

BracketBracket

Figure D: Depth Adjustment

2. Turn the Depth Adjustment Bolt to change

the depth so that the Cut-Off Wheel will not

contact the base at any time during cutting.

3. After adjustment, tighten the Nut down against

the bracket to lock the adjustment in place.

Setting Up an Angle Cut

1. To cut at various angles (up to 45º),

adjust the Angle Scale by loosening the

two Bolts as shown in Figure E.

2. Adjust the Angle Scale to the desired

setting and then tighten both Bolts.

Angle

Scale

Upper Two

Screw Holes

Bolts

Figure E: Angle Scale

3. To reposition the Angle Scale for a wider

workpiece, remove both of the Bolts and reattach

the Angle Scale at the upper two screw holes.

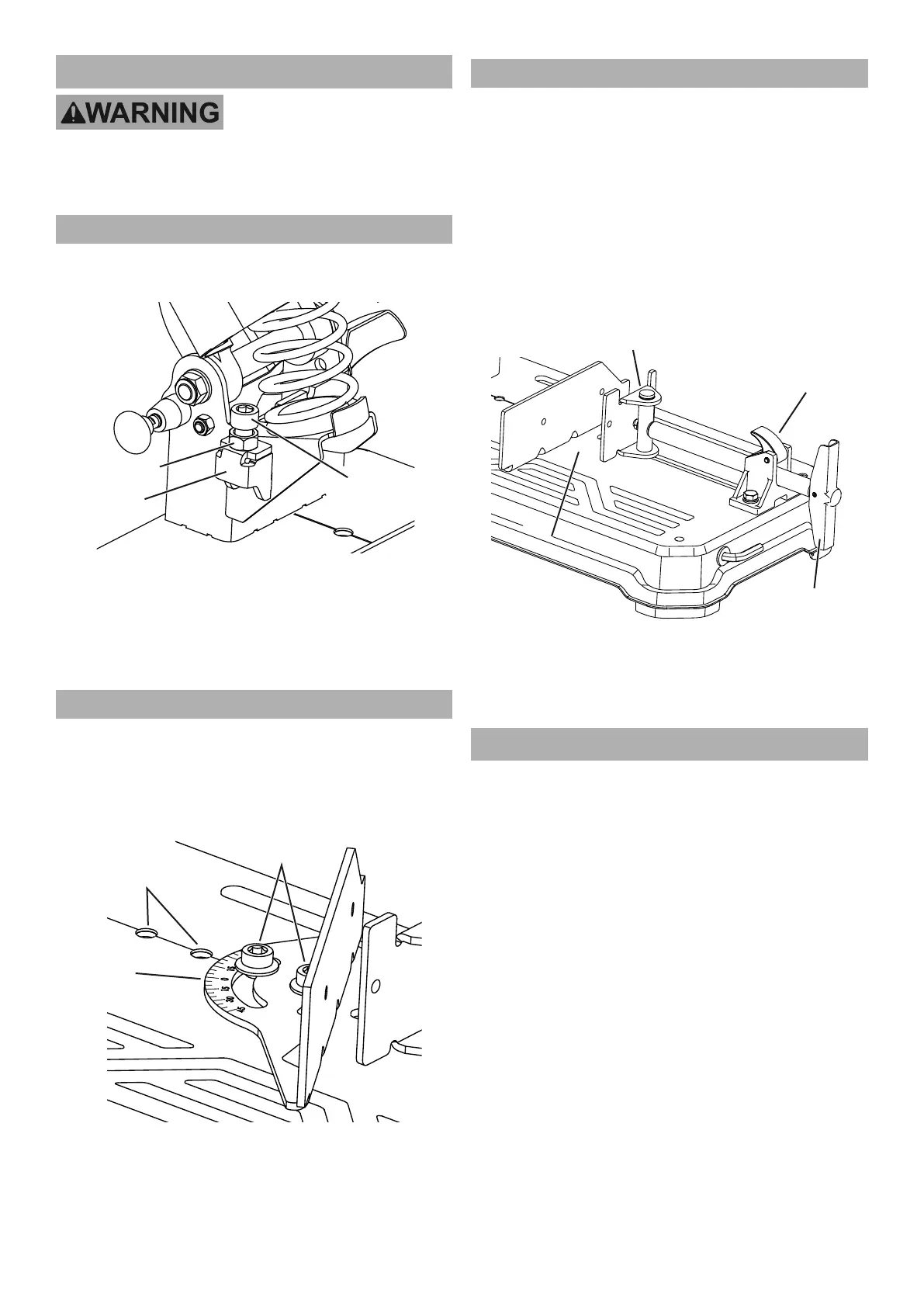

Using the Vise

1. After setting the cutting angle, secure

loose work pieces using the Vise to

prevent movement while working:

a. Lift up the Quick Release to the released

position and push the Vise Handle until the

Vise Clamp is up against the workpiece.

b. Put the Quick Release in the engaged

position shown and tighten the

Vise Handle to secure the workpiece.

Note: To cut the workpiece at an angle,

see Setting Up an Angle Cut.

Place Workpiece Place Workpiece

HereHere

Quick

Release

Vise Clamp

Vise Handle

Figure F: Vise Components

2. To release the workpiece, loosen the Vise Handle

a few turns, lift up the Quick Release and pull the

Vise Handle out to release the Vise Clamp.

Workpiece and Work Area Set Up

1. Designate a work area that is clean and well lit.

The work area must not allow access by children

or pets to prevent distraction and injury.

2. Route the power cord along a safe route to reach

the work area without creating a tripping hazard or

exposing the power cord to possible damage. The

power cord must reach the work area with enough

extra length to allow free movement while working.

3. Allow room on both left and right of

saw for extended workpieces.

4. There must not be objects, such as utility lines,

nearby that will present a hazard while working.

5. Secure workpieces to the saw table using

the Vise to prevent movement during the

cutting operation. Securing the workpiece will

provide safety by removing the need to hold

workpieces near the Cut-Off Wheel by hand and

also improve cutting accuracy by preventing

the workpiece from moving when cutting.

Loading...

Loading...