28

for the technician

First firing, regulation and servicing instructions

Gas transformation

ATTENTION: the operations described below must be carried out only by qualified

personnel [authorized from HERMANN Ltd].

For gas conversion, use the nozzles supplied by boiler manufacturer only.

Using LPG, it is absolutely necessary to install a pressure reducer upstream the boiler.

1. while boiler is not working (green light flashing), select

parameter 1. Push knobs

or according

to:

0 for natural gas working

1 for LPG working

and store pressure pushing

;

2. Check that pressure and gas input are enough to

guarantee the correct functioning of the appliance.

3. Disconnect the boiler from the supply.

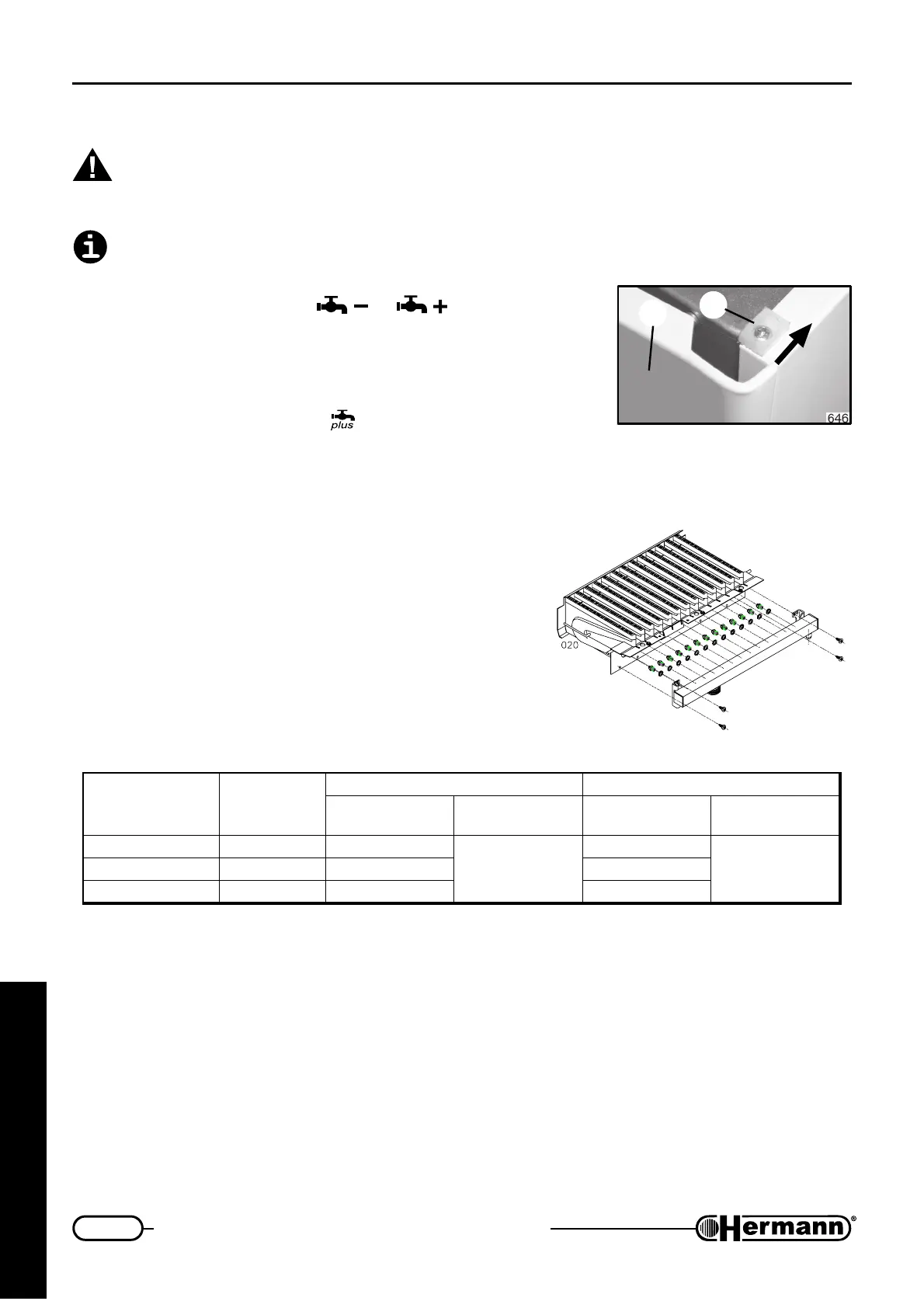

4. Remove front cover: unscrew screws located above

boiler, shift small blocking plate [1], remove front cover

[2] lifting it up. On “SE” models, open sealed combustion

chamber.

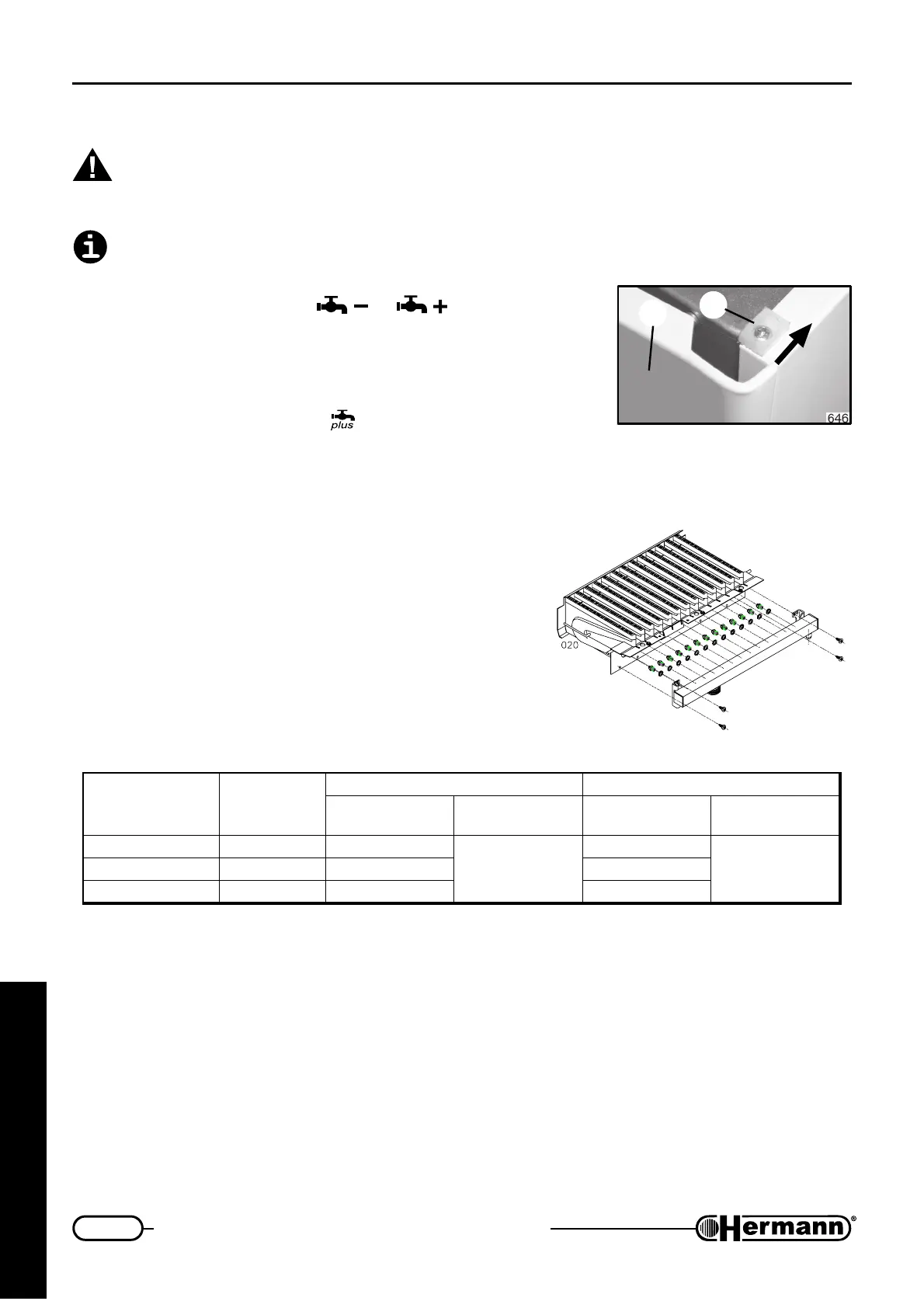

5. Disassemble pipe connecting Gas valve with burner.

6. Remove ramp containing nozzles and substitute it with

correct one, using a 7mm spanner. Reassemble ramp

and pipe, substituting gaskets. On “SE” models, close

sealed combustion chamber.

LEDOM

forebmuN

selzzon

02GSAGLARUTAN13G/03GGPL

ØselzzoN

)mm001/1(

erusserpsaG

)rabm(

ØselzzoN

)mm001/1(

erusserpsaG

)rabm(

ES/E32ARUE31021

02

57

73/03ES/E82ARUE5102157

ES23ARUE5103177

7. Check, with burner ON, that there are no gas leaks and that the pressure upstream the boiler

is:

Natural gas: min.17 – max. 25 mbar

Buthane: min. 25 – max 35 mbar

Propane: min. 25 – max 37 mbar

RAMP AND NOZZLES

REMOVAL

1

2

Loading...

Loading...