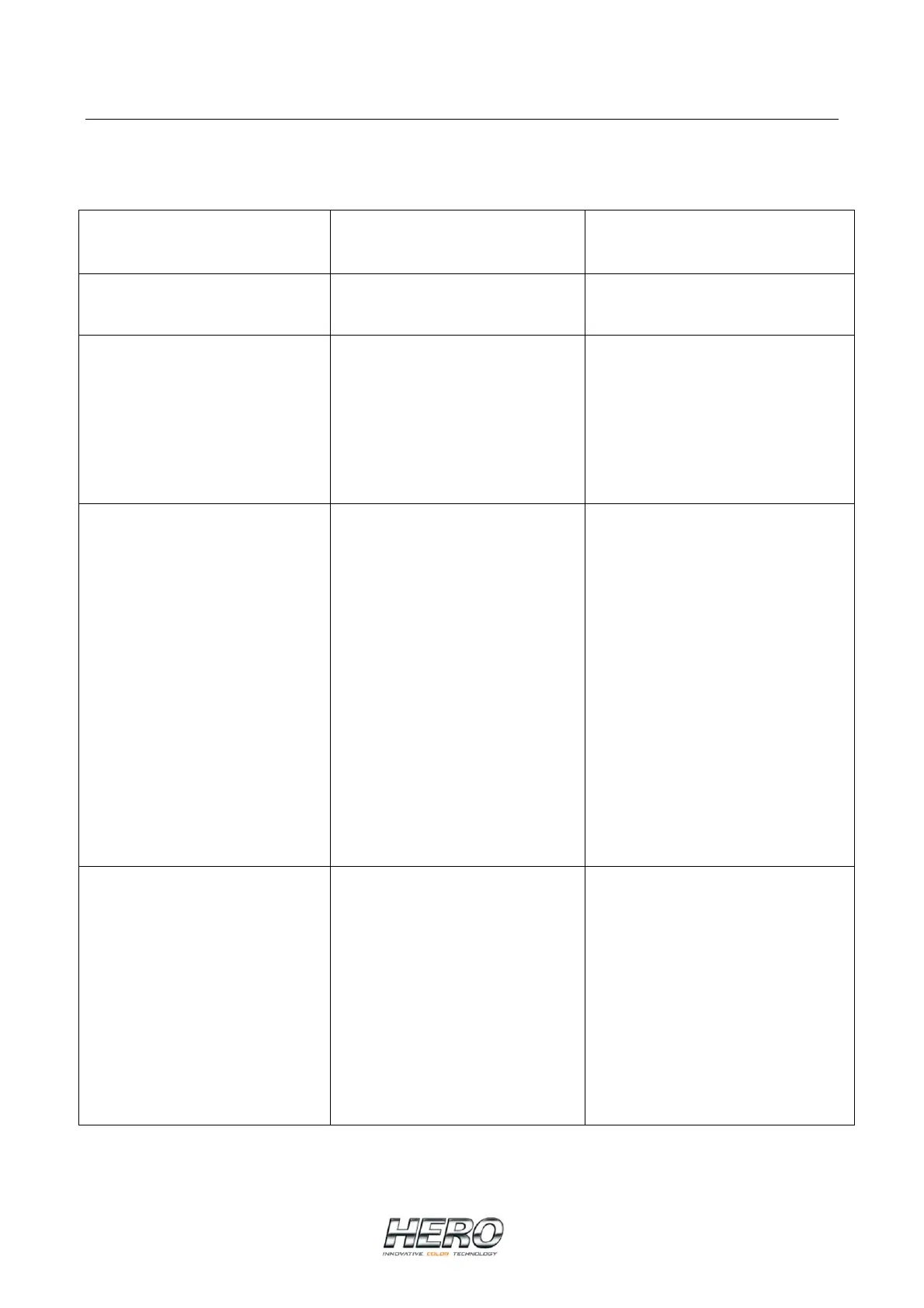

TROUBLESHOOTING CHART

Contact HERO’s 24/7 Help Desk with any questions: 1-800-494-4376

Colorant leaking from the stepper

motor connected to the cartridge

pump

Colorant dripping from the nozzle

Aerated colorant

Dirty nozzle

Damaged nozzle tip

Pull-back feature not set correctly

Dispense colorant until you see a

regular colorant flow without air

Clean nozzle tips and sponge

Replace nozzle

Reprogram pull-back parameters

In software

While dispensing, the pump makes

an irregular pitch noise, sounding

louder than normal. Very little or no

colorant dispenses when pump

makes loud noise

Stuck or stalled pump

The connecting cable between

the PCB and the pump motor is

not properly connected

Damaged connecting cable

between the PCB and the pump

motor

Stepper motor malfunction

PCB is not working correctly

Colorant may be too thick. Move the

pump rotor by hand by turning the

bolt in the bottom center of the

stepper motor. Turn it clockwise

several times and try to run the pump

again by dispensing 5 oz of product.

Thin or replace the colorant if

necessary

Check that the connectors at both

ends of the cable are inserted

all the way

Replace the cable

Replace the pump cartridge

Replace the PCB

PC no longer recognizes the

dispenser and/or

No communication message

and/or

All of the agitation motors do not

work and/or

The laser aiming device does not

work and/or

The automatic nozzle cap does not

open and/or

None of the pump motors run

No AC power to the dispenser

No output from one or the other

power supplies

PCB is not working correctly

Check the dispenser’s power

source and switches, inc. emergency

switch and AC fuse on the rear panel

Unplug the dispenser and check

that all wiring is firmly connected

to all power supplies and the PCB.

Power up the dispenser and

carefully use a voltmeter to check

the input and output of each

power supply. Replace a power

supply with input but no output

Replace the PCB

Loading...

Loading...