13

5. Parameter settings

5.1 Control parameters

This option makes it possible to change the value of parameters available in the selected installation scheme. In order to change parameters:

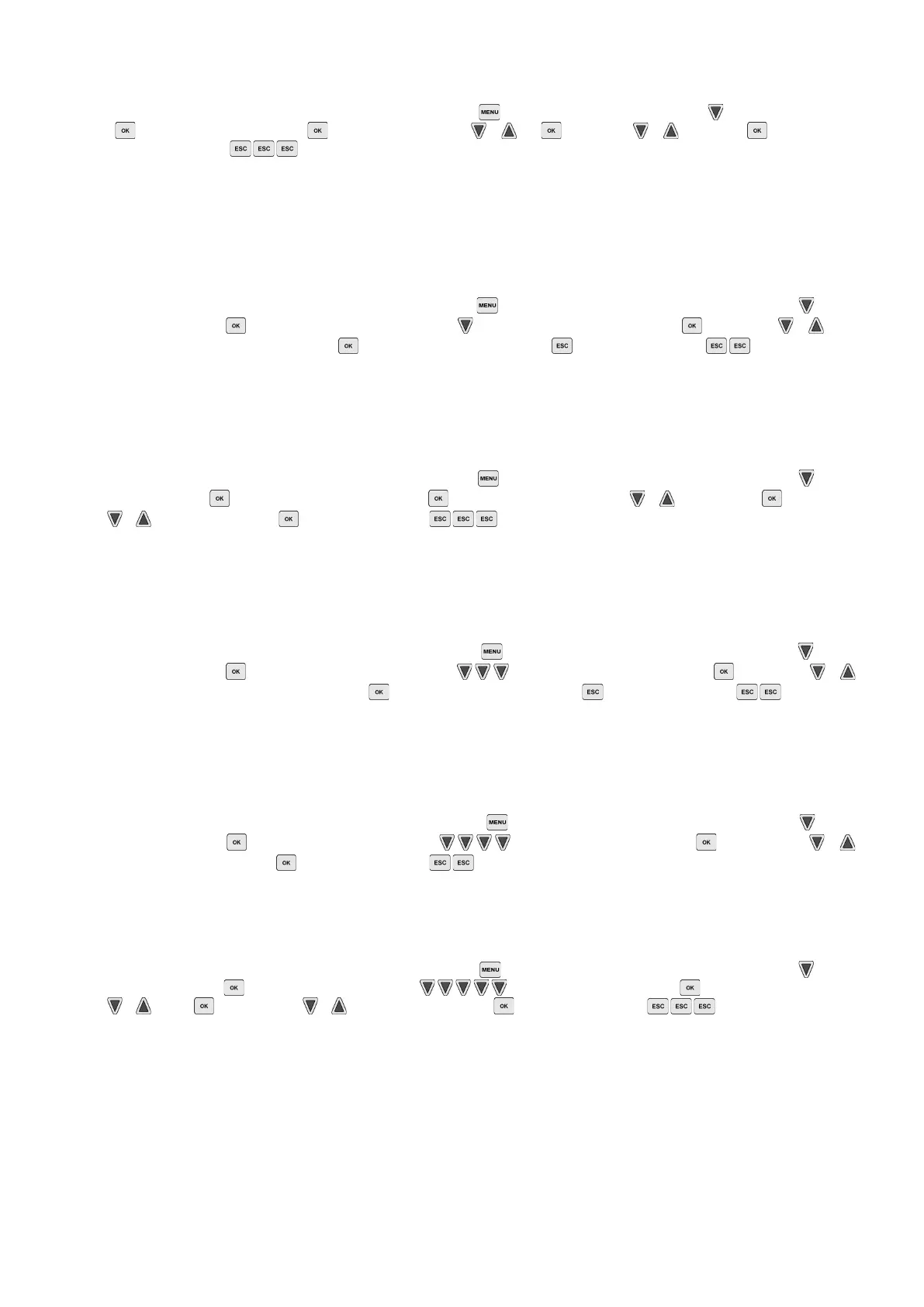

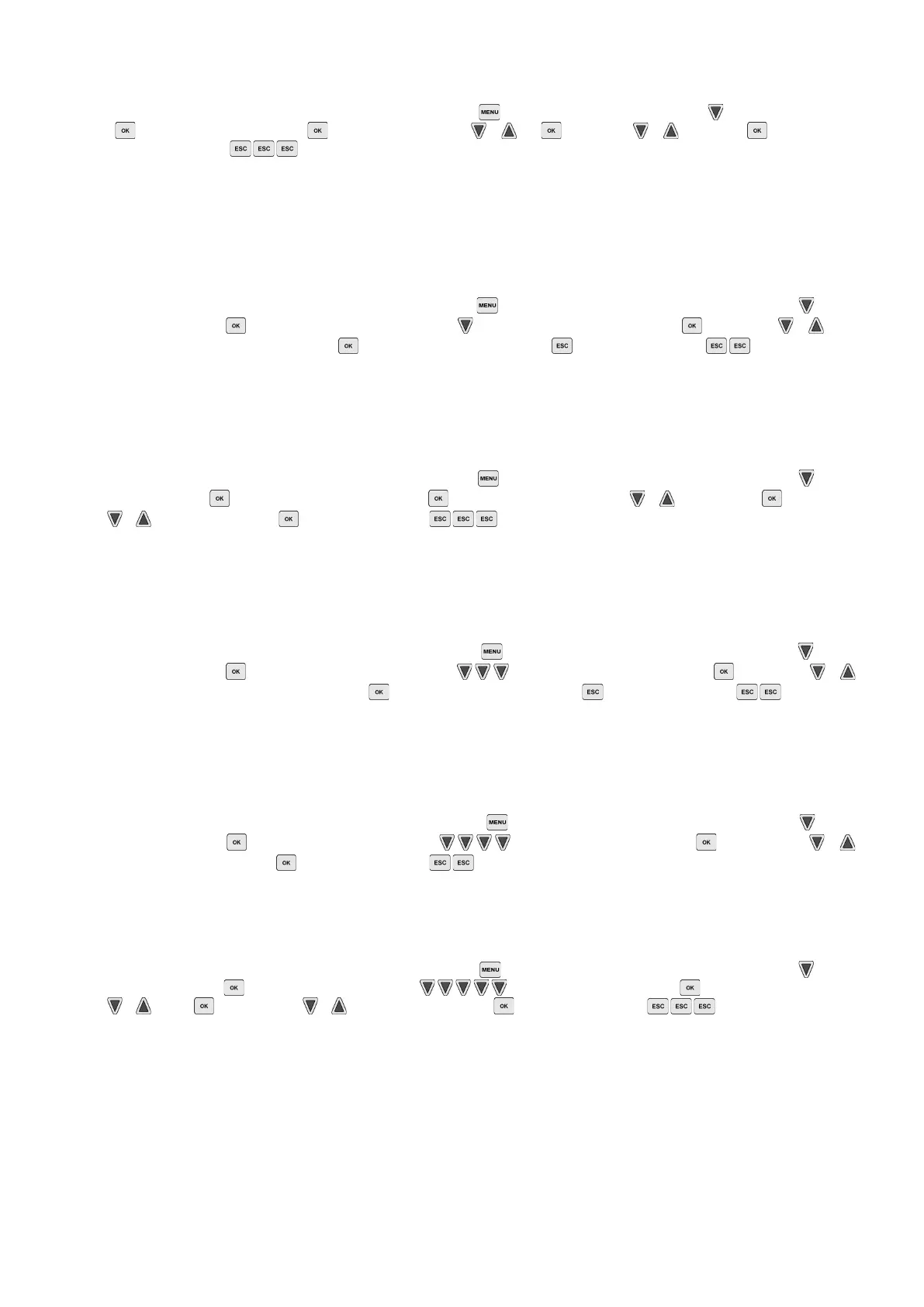

Press the following key combination: starting point - MAIN SCREEN: entry into the MENU , get to the option named Parameters settings , enter the Parameter settings

menu , get to the Control parameters option , choose appropriate parameters or , edit , change values or , accept values (a continuous sound

signal), return to the main screen .

ATTENTION ! Description of all the available parameters can be found in Table 3 – pages16-17

The display shows current option level and the controller values with the use of the ▼and ▲ cursors. The down cursor ▼ shows that there are parameters available

below the currently displayed options, whereas the up cursor ▲, indicates that there are parameters available above the currently displayed ones. The combination of

buttons for selected scheme no 3 is presented below.

5.2 Time program C

This option allows for setting a time program in which a device denoted by C (circulation pump, pool pump) in a given installation scheme will be working. In order to set or change the

C time program of devices:

Press the following key combination: starting point - MAIN SCREEN: enter the MENU with (enter password), get to the option named Parameters settings with , enter the

Parameter settings menu with , get to the option named Time program C with , enter the option named Time program C with , select time with or , accept

operation time (white square) or cancel operation time with , accept and return (a continuous sound) with , return to the main screen with .

ATTENTION ! Time intervals are divided into 24h operation periods, settings for each hour are selected separately by marking it with a white square. The number of

squares marks the number of operation hours. Week days have been divided into three groups: Monday - Friday (Mo-Fr), Saturday (Sat), Sunday (Sun).

5.3 Circulation parameters

This option allows for setting all parameters connected with the operation of the tap water circulation pump. To change parameters of the C pump:

Press the following key combination: starting point – MAIN SCREEN: enter the MENU with (enter password), get to the option named Parameters settings with , enter the

Parameters settings menu , get to the option named Circulation param. , select the parameter to be changed with or , edit the parameter , change its value

with or , accept (a continuous sound) , return to the main screen with .

ATTENTION! For description of all available parameters for the circulation pump, see Table 3 – pages 16-17

5.4 Time program K

This option allows for setting a time program in which a device denoted by K (boiler, electrical heat, heat pump) in a given diagram will be working. In order to set or change the K time

program of devices:

Press the following key combination: starting point - MAIN SCREEN: enter the MENU with (enter password), get to the option named Parameters setting with , enter the

Parameter settings menu with , get to the option named Time program K with , enter the option named Time program K with , select time with or ,

accept operation time (white square) or cancel operation time with , accept and return (a continuous sound) with , return to the main screen with .

ATTENTION! Hourly setting of K are identical to those of the Time program C.

5.5 Heat transfer fluid

A parameter connected with liquid specific heat, it corresponds to a given solidification temperature of a heat carrier. In order to define this parameter read liquid solidification

temperature from the package or contact the seller. In order to set or change the solidification temperature of the liquid used:

Press the following key combination: starting point - MAIN SCREEN: entry into the MENU with (enter password), get to the option named Parameters setting with , enter the

Parameter settings menu with , get to the option named Heat carrier with , enter the option named Heat carrier with , change values with or ,

accept and return (a continuous sound) with , return to the main screen with .

ATTENTION ! This parameter is needed for correct calculation of solar collector instantaneous power and summing thermal energy.

5.6 Flow rate

A parameter connected with heat carrier flow. In order to make correct settings:

Press the following key combination: starting point - MAIN SCREEN: enter the MENU with (enter password), get to the option named Parameters setting with , enter the

Parameter settings menu with , get to the option named Flow rate with , enter the option named Flow rate with , select the parameter to be changed

with or , edit with , change values with or , accept (a continuous sound) with , return to the main screen with .

ATTENTION ! Correct flow rate depends on the sort of collectors, type of collectors and overall dimensions.

Set the recommended minimum flow rate to 0.3 l/min for 1 m

2

of active area of the collector (example: 2 collectors with active area of 2.0 m

2

each – minimum flow rate is: 2

2 = 4

0.3 = 1.2 l/min.

Set the nominal (maximum) flow rate to 1 l/min for 1 m

2

of active area of the collector (example: 2 collectors with active area of 2.0 m

2

each – nominal flow rate is: 2

2 = 4

1.0 =

4.0 l/min.

The controller enables cooperation with a mechanical rotameter or an electronic flow meter of the G-916 type or any other electronic flow meter.

Select the main flow meter connected to FLOW1 terminals. The second flow meter connected to FLOW2 terminals is by default set as Electronic G-916.

Measurement: Electr.G916 – cooperation with an electronic G-916 flow meter. The controller reads the number of impulses and converts it into the real flow (liters per minute).

Nominal flow rate – entry to the nominal flow rate option results in switching P collector pumps on with maximum efficiency. Enter the calculated flow rate value that

results from the number of collectors in the system into the edition field. Next, set the required flow in such a way that the “Current” value corresponds to the calculated

value entered before. The required flow can be obtained by changing the rotational speed in option Collector Pump.

Loading...

Loading...