English

8

g) Support any oversized workpiece to minimize

the risk of wheel pinching and kickback. Large

workpieces tend to sag under their own weight.

Supports must be placed under the workpiece near

the line of cut and near the edge of the workpiece on

both sides of the wheel.

ADDITIONAL SAFETY WARNINGS

1. Use the normal cut-off wheel on its normal working

surface.

2. Guard against cut-off sparks.

3. Properly replace the cut-off wheel.

4. Always pay attention that the cut-off wheel clamping

parts are never impaired. Defective parts will cause

damage to the cut-off wheel.

5. Ensure that the workpiece is free of foreign matter such

as nails.

6. Abrasive wheels shall be stored and handled with care in

accordance with manufacturer’s instructions.

7. Ensure that mounted wheel are fi tted in accordance with

the manufacture’s instructions.

8. Do never use the machine without the guard in place.

Always use the blade guard. A blade guard protects

the user against broken off parts of the cutting disc and

against accidental touching of the cutting disc.

9. Make sure that the guard operates properly and that it

can move freely. Never lock the guard in place when

opened.

10. Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more secure than by

hand.

11. Do not use saw blade.

12. Store the machine in a safe manner when not being

used. The storage location must be dry and lockable.

This prevents the machine from storage damage, and

from being operated by untrained persons.

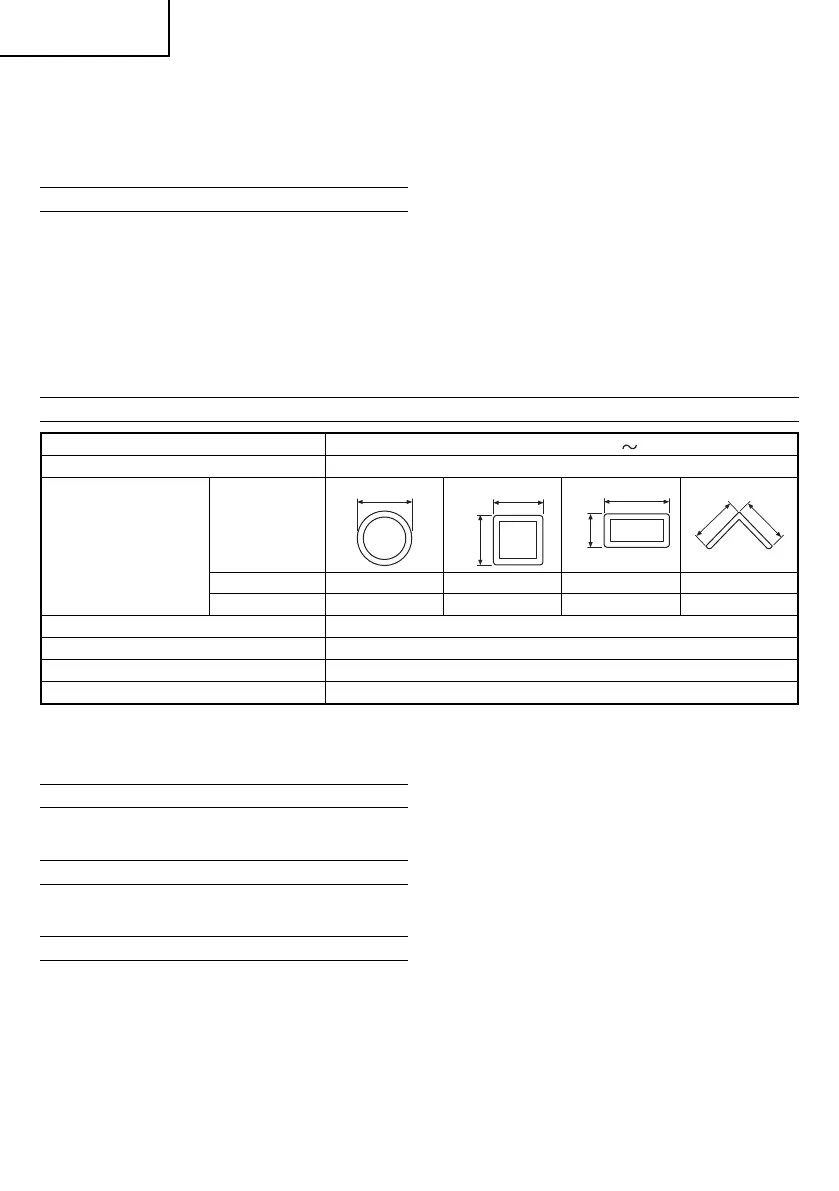

SPECIFICATIONS

Voltage (by areas)*

1

(220 V, 230 V, 240 V)

Power Input*

1

2200 W

Max. cutting dimensions*

2

Height × width

Shape of material

to be cut

A

A

A

B

A

A × B

A

A

Cutting angle 0° 120 mm 115 mm 90 mm × 200 mm 130 mm

Cutting angle 45° 115 mm 104 mm

110 mm × 104 mm

100 mm

Cut-off wheel ø355 × ø25.4 × 4 mm (Reinforced resinoid cut-off wheel)

No-load Speed 4100 min

-1

Max. working peripheral speed 4800 m/min

Weight 17.0 kg

*1 Be sure to check the nameplate on product as it is subject to change by areas.

*2 The maximum cutting dimensions are the permissible cutting dimensions when the cut-off wheel is not remarkably worn

by cutting material.

STANDARD ACCESSORIES

(1) Cut-off wheel ................................................................. 1

(2) Hex. bar wrench ............................................................ 1

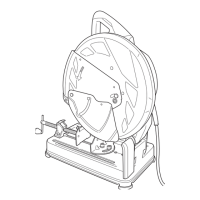

APPLICATIONS

Cutting of various metallic materials such as pipes, round

bars and shaped steel.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If the

plug is connected to a receptacle while the power switch

is in the ON position, the power tool will start operating

immediately, which could cause a serious accident.

3. Extension cord

When the work area is removed from the power source,

use an extension cord of suffi cient thickness and rated

capacity. The extension cord should be kept as short as

practicable.

4. Install the machine on a level fl at place, and keep it in

a stable condition. Prior to shipping, the equipment is

subjected to a rigid factory inspection to prevent electric

shocks during operation.

5. Since movable portions are secured by tension of a chain

while in transit, remove the chain from the chain hook by

slightly depressing the switch handle.

6. Ascertain that all cut-off wheels are in perfect condition,

and do not display scars and cracks.

7. Although they have been fully clamped at the factory

prior to delivery, reclamp the clamping nuts securely for

safety.

8. Possible accidents such as a cracked cut-off wheel

is prevented by this protective cover (wheel cover).

Although it has been fully clamped at the factory prior

to delivery, securely reclamp the mounting screws for

safety.

000BookCC14STTurUkRu.indb8000BookCC14STTurUkRu.indb8 2019/01/219:54:502019/01/219:54:50

Loading...

Loading...