1.3 Setback and corresponding safety instructions

Setback is the sudden reaction resulting from a hooked or jammed rotating insert tool. Hooking or jamming causes an abrupt stop of the

rotating insert tool. This causes an uncontrolled power tool to accelerate against the direction of rotation of the insert tool at the jamming

point. For example, if a grinding wheel hooks or jams in the workpiece, the edge of the grinding wheel that plunges into the workpiece

may become caught, causing the grinding wheel to break away or kick back. The grinding wheel then moves towards or away from the

operator, depending on the direction of rotation of the wheel at the jamming point. Grinding wheels can also break during this process.

Kickback is the result of incorrect or faulty use of the power tool. It can be prevented by taking appropriate precautions as described

below.

- Hold the power tool firmly and put your body and arms in a position where you can absorb the recoil forces. Always use the auxiliary

handle, if available, to have the greatest possible control over recoil forces or reaction moments during run-up. The operator can

control the recoil and reaction forces by taking appropriate precautions.

- Never bring your hand close to rotating insert tools. The insert tool may move over your hand during recoil.

- Avoid the area with your body where the power tool will move during a kickback. The kickback drives the power tool in the direction

opposite to the movement of the grinding wheel at the jamming point.

- Be especially careful when working around corners, sharp edges, etc. Prevent insert tools from bouncing off the workpiece and

jamming. The rotating insert tool tends to jam at corners, sharp edges or when it bounces off. This causes a loss of control or kickback.

- Do not use a chain or toothed saw blade. Such insert tools often cause kickback or loss of control of the power tool.

1.4 Special safety instructions for sticking

- Do not work on surfaces with exposed steel reinforcements. Danger of kickback!

- Take special care when machining corners, edges and extreme transitions. Damage to the milling head or the milling wheels is

possible.

- Only operate the power tool when the milling wheels can rotate freely.

- Only use original Wibec "Xposer milling discs".

2. Technical data

Power supply voltage V/Hz 230/50

Protection class / II

Power consumption W 1250

Speed rpm 600 - 1100

Tool holder M14

Weight (included power cable) kg 15

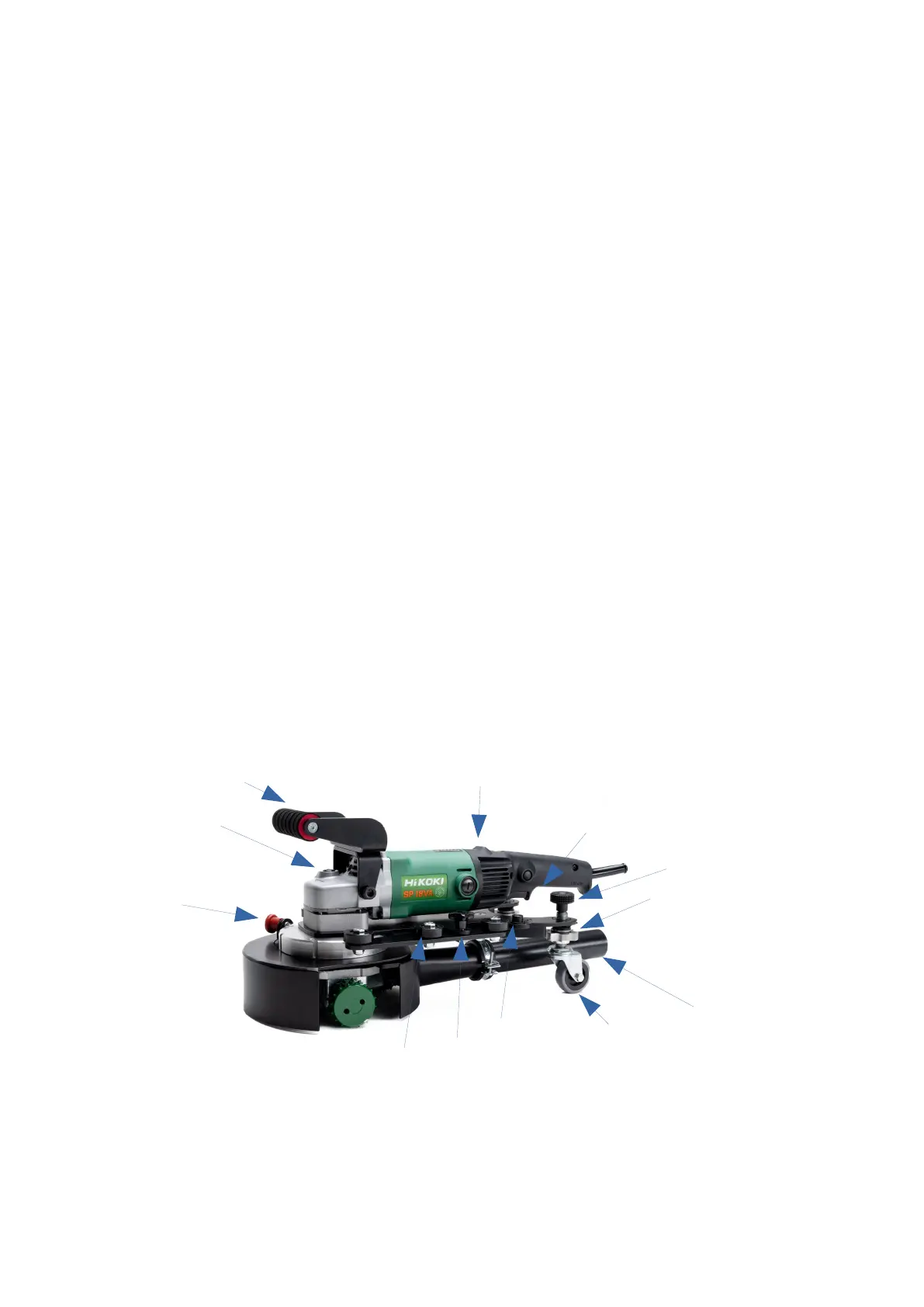

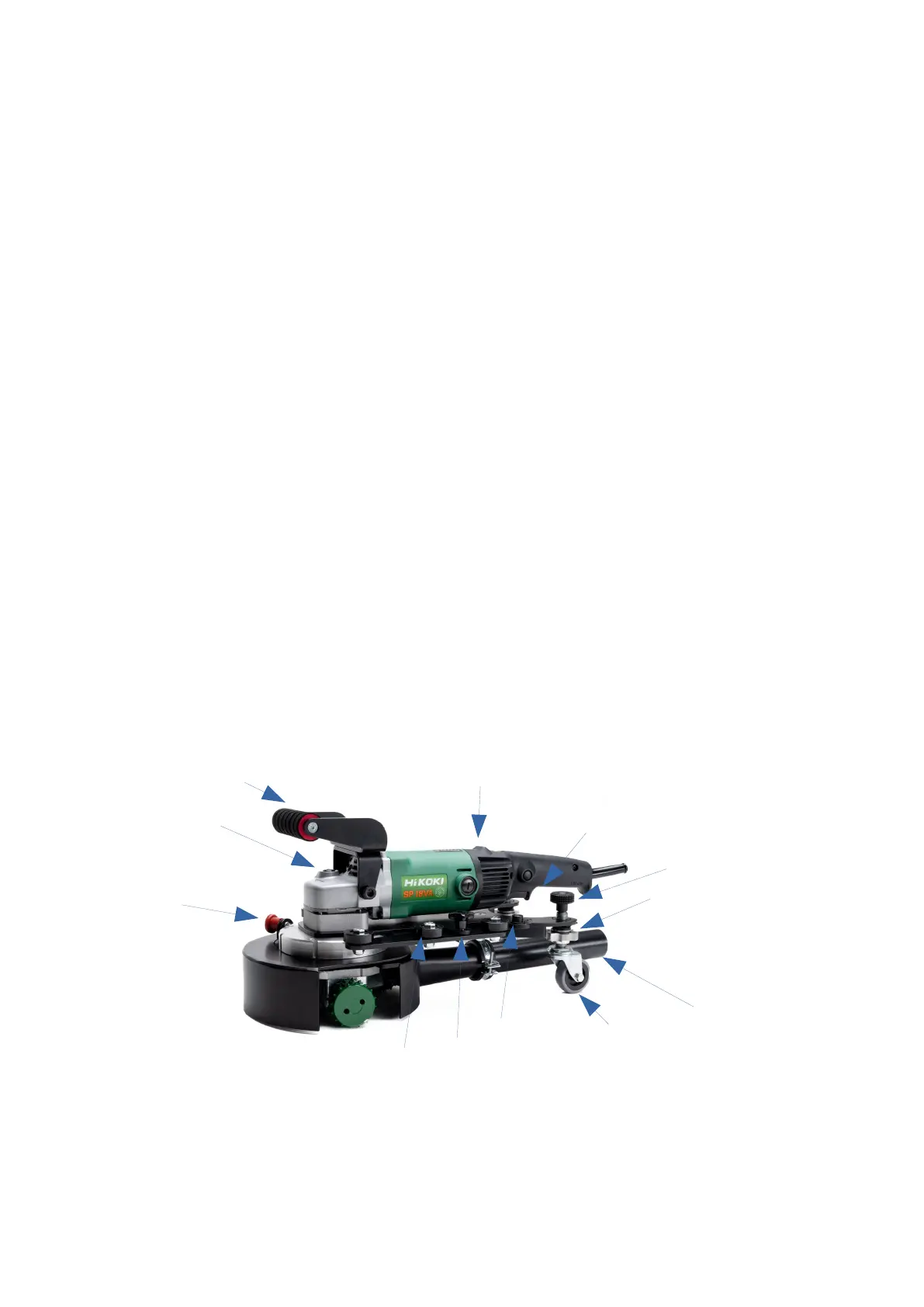

3. At one glance

3

12. Handle

1. Dial for speed selection

2. On/off switch

11. Spindle lock for tool

change

5. Connection for

dust extraction

10. Locking lever

for cover opening

3. Adjusting wheel

for height levelling

4. Locking nut

for height levelling

9. Side guide rails

8. Adjusting screw for

side guide rails

7. Level

6. Support wheel

Loading...

Loading...