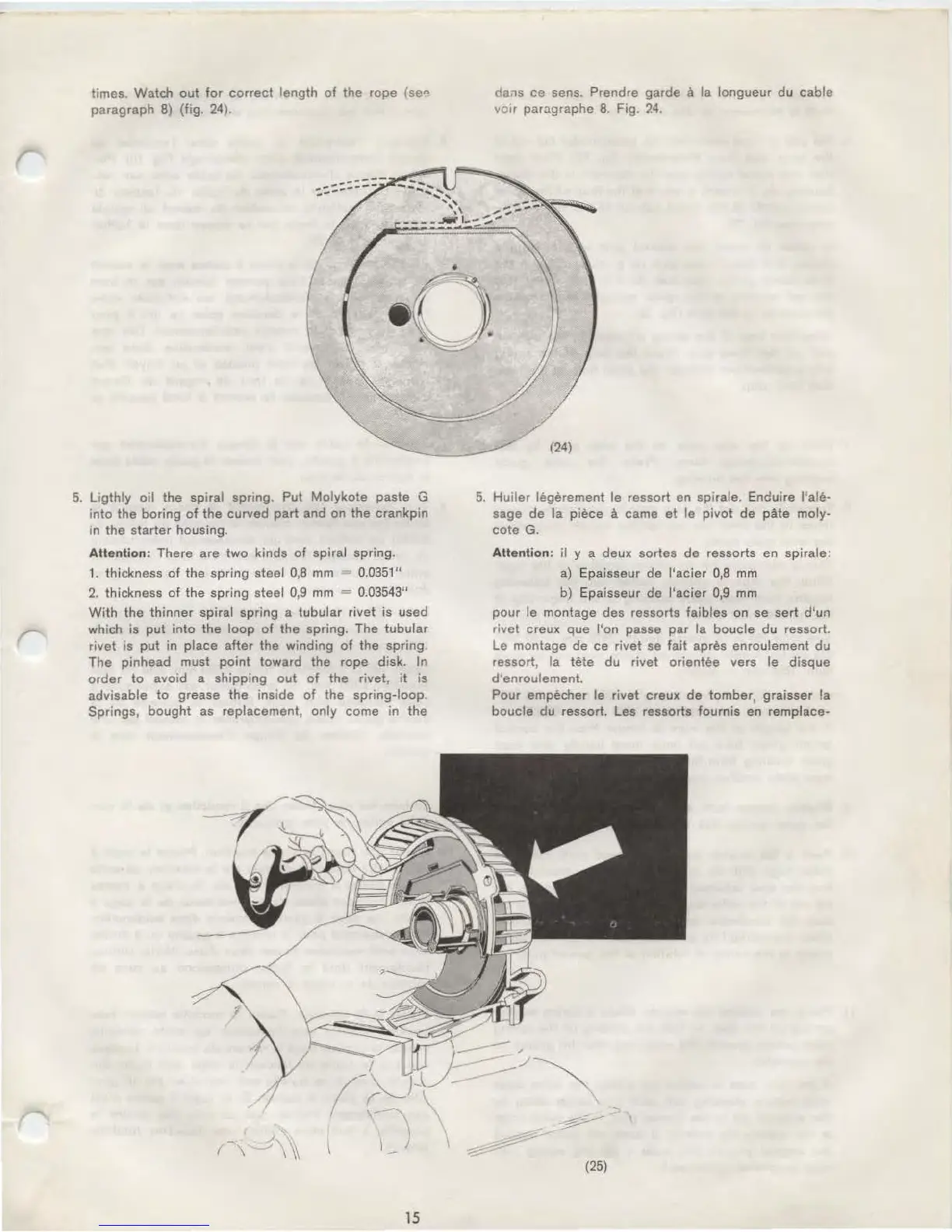

times. Watch

out

for

correct

length

of

the rope

(se"

paragraph

B)

(fig.

24)

.

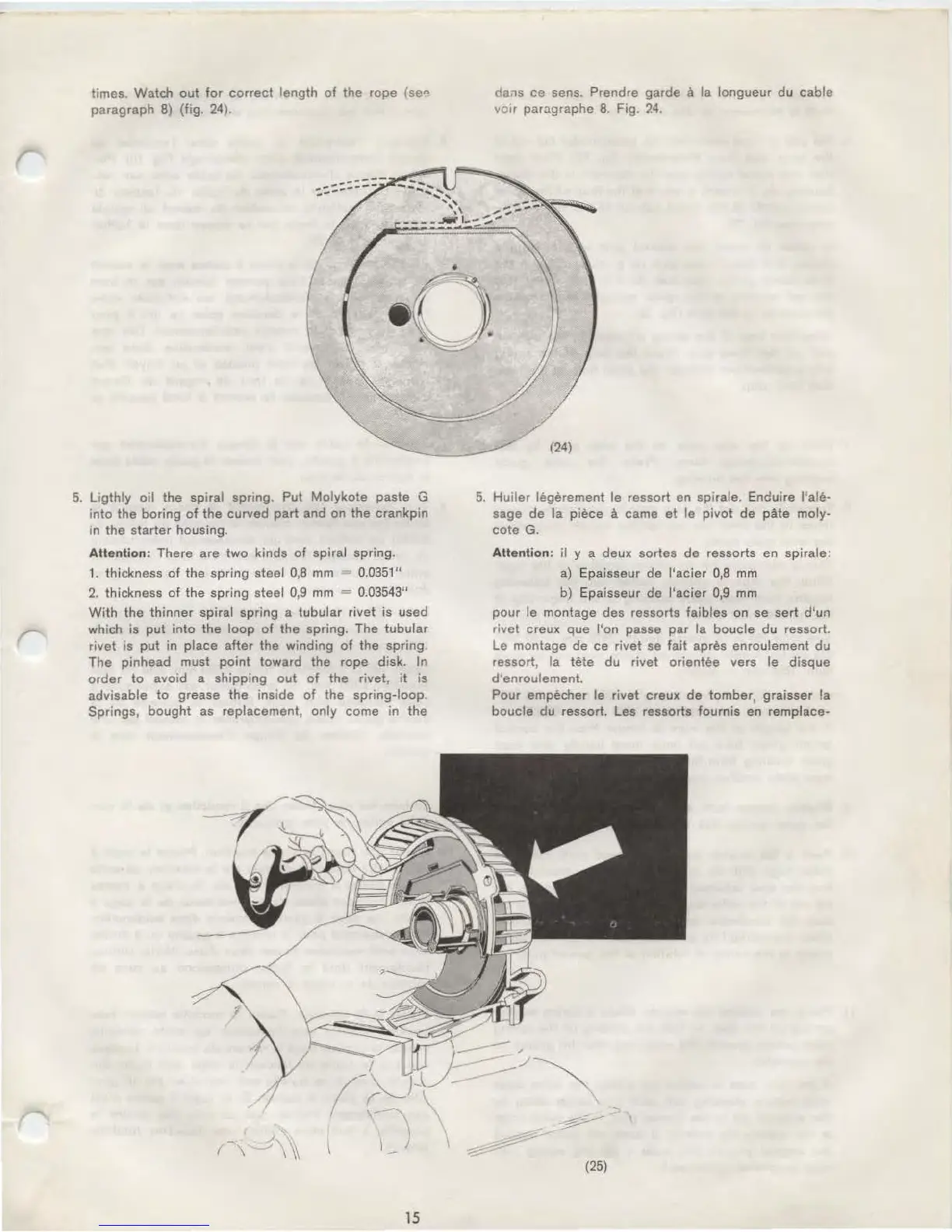

5.

Ligth

ly

oil

the spiral spring. Put

Molykote

paste G

i

nto

the

boring

of

the curved

part

and on the crankpin

in

the

starter housing.

Att

en

ti

on: There are two kinds

of

spiral spring.

1.

thickness

of

the spring steel 0,8

mm

0.0351"

2.

thickness

of

the spring steel 0,9

mm

= 0.03543"

With

the thinner spiral spring a tubular rivet is used

which is

put

into

the loop

of

the spring. The

tubular

rivet

is

put

in

place

after

the winding

of

the spring.

The

pinhead must

point

toward the rope disk. In

order

to

avoid

a shipping out

of

the

rivet

,

it

is

advisable

to

grease the ins1

de

of

the spring-loop.

Springs

,

bought

as

replacement, only come in the

15

da;~

s

ce

sens. Prendre

garde

a Ia longueur du

cable

vo1r

paragraphc 8 Fig.

?4

.

5.

Huiler legerement le ressort en

sp

irale. Enduire !'ale-

sage

de

Ia piece a came

et

le

pivot

de

pate moly-

cote

G.

Att

ention: il y a deux sortes

de

ressorts en spirale:

a)

Epaisseur de

l'acier

0,8

mm

b) Epaisseur de

l'acier

0,9

mm

pour

le

montage des ressorts faibles on se

sert

d'un

riv

et

creux que l'on passe

par

Ia boucle

du

ressort.

Le montage

de

ce

rivet

se

fait

apres enroulement du

ressort,

Ia tete du rivet

or

ientee vers le disque

d'enroulement.

Pour empecher le rivet creux de

tomber

, graisser Ia

boucle

du ressort. Les ressorts fournis en remplace-

(25)

Loading...

Loading...