10

LINE DIAMETER

DIAMETER OF GAS LINES

In the cooling operation suction line

hold gas refrigerant and in the heat

pump operation discharge line is also

gas line. Line diameter is selected in the

most unfavourable conditions. It is nec-

essary to check for both cases.

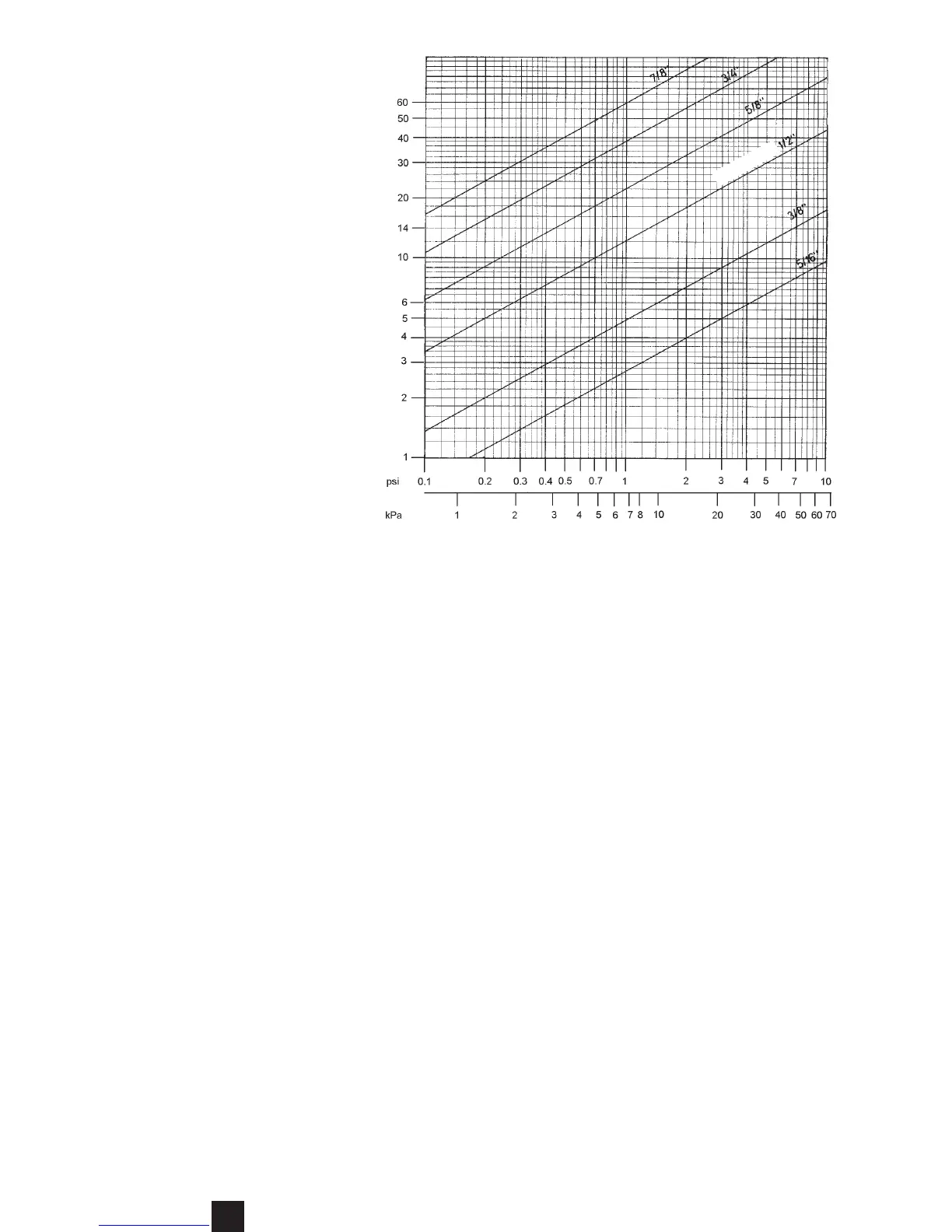

In the case of the layout shown on fig-

ure 2 the suction line velocity will pro-

duce the worse conditions and gas line

diameter selection is for suction line. It

is necessary to check also the discharge

line. The suction and discharge calcu-

lations are done in the same way using

graphs 1 and 2 where pressure are re-

ferred to 10 meters of equivalent length

for each diameter.

For larger or smaller equivalent lengths

pressure drop is obtained in the direct

proportion. The line total pressure drop

(horizontal plus vertical pipe runs) must

never be higher than 20 kPa.

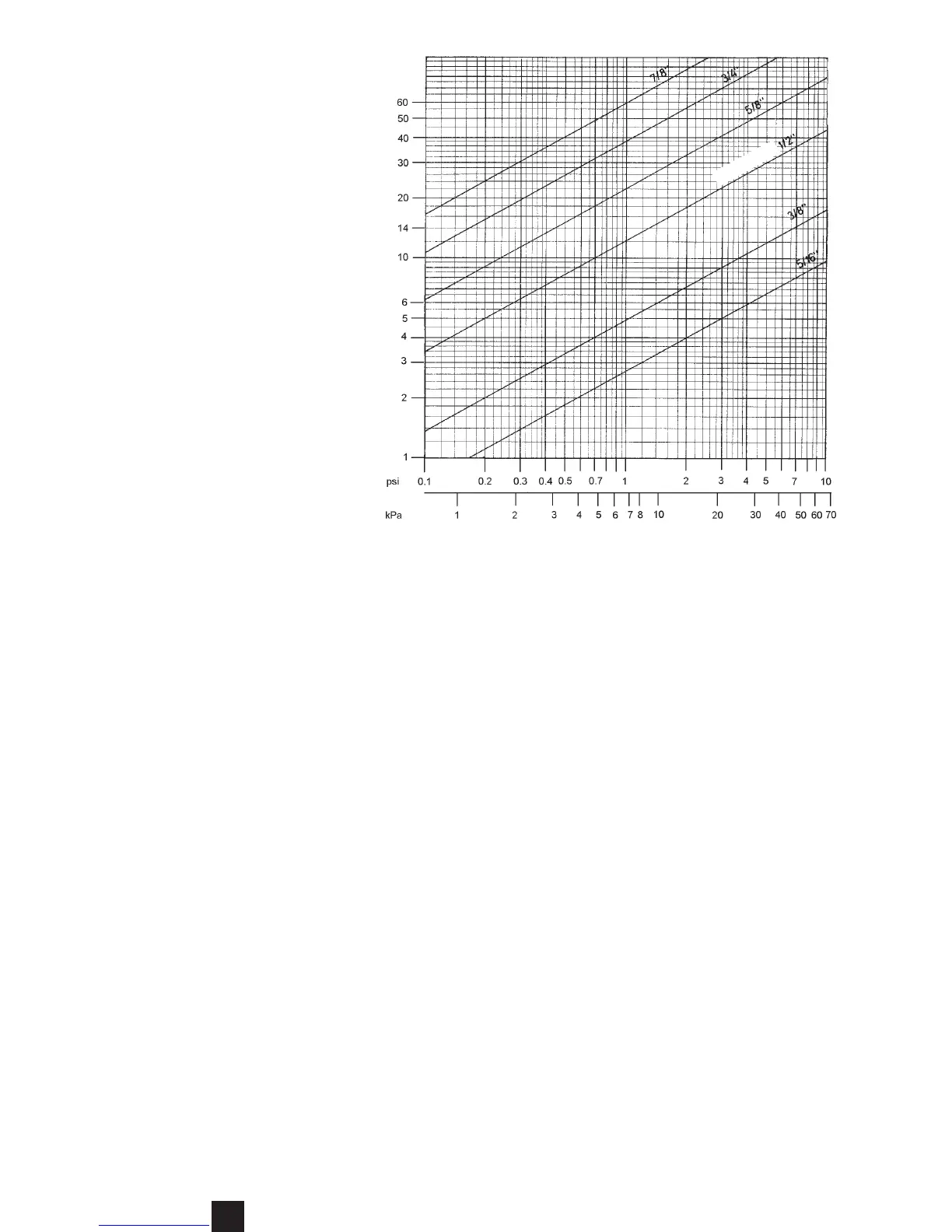

DIAMETER OF LIQUID LINES

To determine the liquid line diameter

use graph 3, the pressure drop in this

line should be below 68 kPa.

Nominal cooling capacity (kW) of one circuit

Pressure drop per 10 m. of equivalent length

Diameter

Graph 3 - Liquid line.

START UP

PRELIMINARY CHECK UP

It is very important to check the following points be-

fore first unit start up:

1. All the electrical connections are well tight.

2. Unit is level installed and has proper supporting

structure.

3. Air ducts have been not damaged during the instal-

lation.

4. Air filters are correctly mounted and are clean.

5. All panels are at their place and the screws tights.

6. Unit has easy maintenance and service access.

7. Openings and/or drain connections for rain and de-

frost (heat pumps) water evacuation are not blocked.

8. Check if there are no refrigerant leaks.

9. Electrical power source agrees with the unit name-

plate rating.

10. Check for proper fan rotation.

ATTENTION: The compressors are mounted on vibra-

tion isolators. Check if mounting bolts have been not

loosen or removed by mistake.

UNIT START UP

Start up must be performed by qualified and

trained service personnel.

ATTENTION, CRANKCASE HEATER: to avoid re-

frigerant condensation in the compressor(s) and refrig-

erant absorbtion in oil when not operating, compres-

sors are fitted with a crankcase heater. This electrical

resistance is connected on normally closed contacts

from the compressor(s) contactor(s), thus when main

power of the unit is live the heating is effective only

when the conpressor(s) is(are) not running.

Make sure that this heating element is under power

for at least 24 hours before the first start up of the com-

pressor (thermostat on "OFF" position).

At start up time a check list of all parameters must be

established. Consult, and eventually modify, this check

list when servicing the unit and for maintenance op-

erations.

Loading...

Loading...