Do you have a question about the Hobbywing WP-1040-BRUSHED and is the answer not in the manual?

Configure transmitter settings like D/R, EPA, ATL, and TRIM for ESC compatibility and proper operation.

This document outlines the features, usage, and troubleshooting for a water-proof brushed speed controller (ESC) designed for RC models. It emphasizes the importance of careful reading due to the potential dangers of RC power systems and disclaims liability for damages resulting from product use.

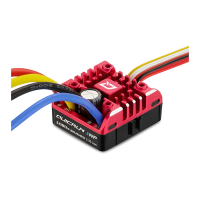

The ESC is designed for all-weather racing, featuring a water-proof and dust-proof construction. Its compact size integrates a capacitor module, simplifying installation. A key operational feature is its automatic throttle range calibration, which makes it easy to set up. The device incorporates multiple protection mechanisms, including low voltage cut-off for Lipo or NiMH batteries, over-heat protection, and throttle signal loss protection, ensuring safe operation. Programming the ESC is made simple through the use of jumpers.

To begin using the ESC, users must connect it to the motor, receiver, battery, and servo according to the provided diagram. It's crucial to ensure correct battery polarity to prevent immediate damage to the ESC. The control cable, consisting of black, red, and white wires, connects to the receiver's throttle channel, typically CH2. The motor's positive and negative wires connect to the ESC without a specific order; if the motor runs in the opposite direction, users should simply swap these two wire connections.

Before operation, the transmitter must be properly configured. Users should set the "D/R," "EPA," and "ATL" for the throttle channel to 100% (or maximum value for transmitters without LCDs) and the "TRIM" of the throttle channel to 0 (or neutral position). For Futaba™ and similar transmitters, the throttle channel direction should be set to "REV," while other radio systems should be set to "NOR." Activating the "Fail Safe" function on the radio system is strongly recommended to ensure the motor stops if a signal is lost.

Throttle range calibration is a necessary step to match the ESC with different transmitters. This involves turning on the transmitter, keeping the throttle stick at its neutral position, and waiting for 3 seconds for the ESC to perform a self-test and automatic throttle calibration. A long beep from the motor indicates successful calibration and readiness for operation. It's important to recalibrate the throttle range if a new transmitter is used or if any settings related to the neutral position, D/R, ATV, ATL, or EPA parameters of the throttle channel are changed, as improper calibration can prevent the ESC from functioning correctly.

The ESC provides audible beep sounds and LED indicators to communicate its status. A single short beep signifies a NiMH/NiCd battery, two short beeps indicate a 2S Lipo battery, and three short beeps indicate a 3S Lipo battery. A long beep confirms that the self-test and throttle calibration are complete and the ESC is ready to run. The LED status also provides visual feedback: the red LED is off when the throttle stick is in the neutral range, blinks at partial throttle (forward, brake, or reverse), and remains solid at full throttle (forward, brake, or reverse).

Programming the ESC is done using jumpers, with tweezers recommended for plugging and unplugging them. The device includes several protection functions. The low voltage cut-off protection activates if the battery pack voltage drops below a threshold for 2 seconds, reducing and eventually cutting off output power. The thresholds are 6.2V for 2S Lipo, 9.3V for 3S Lipo, and 4.5V for 5 to 9 cells NiMH/NiCd. When this protection is active, the red LED blinks. Over-heat protection engages if the ESC's internal temperature exceeds a preset threshold for 5 seconds, reducing and cutting off output power. The red LED blinks when over-heat protection is active, and power output recovers to normal once the ESC cools down to 80 degrees Celsius. Throttle signal loss protection cuts off output power if the throttle signal is lost for 0.1 second, reinforcing the recommendation to activate the radio system's "Fail Safe" function.

There are distinct differences between "Brushed" and "Brushed-Crawler" ESCs, primarily in their backward-running modes. The "Brushed" ESC uses a "Double-Click" method for backward movement. When the throttle stick is moved from forward to backward for the first time, the ESC brakes the motor, which slows down but does not stop. Backward action is only activated on the second "click" if the motor speed has reached zero. This method prevents accidental reverse during frequent braking. In contrast, the "Brushed-Crawler" ESC uses a "Single-click" method, allowing the car to go backward immediately when the throttle stick moves from forward to backward. This mode is common for Rock Crawlers and tanks. Additionally, the maximum reverse force for backward-running is 50% for the "Brushed" ESC and 100% for the "Brushed-Crawler" ESC.

Troubleshooting guidance is provided for common issues. If the motor doesn't work, no sound is emitted, and the LED is off after power-on, it could indicate that the ESC isn't receiving working voltage due to broken connections between the battery pack and ESC, or a damaged switch. Solutions involve checking battery wire connections, replacing defective connectors, or replacing the switch. If the motor doesn't work and the red LED blinks after power-on, it suggests an abnormal throttle signal or failed automatic throttle calibration. Users should check throttle wire connections, ensure it's plugged into the correct receiver channel, and set the throttle channel's "TRIM" to 0 or its neutral position.

If the car runs backward while giving throttle, or if the motor runs in the opposite direction, the wire connections between the ESC and motor may need to be swapped. If the car can't go backward, it could be due to a wrong jumper position or a changed/drifted neutral point of the throttle channel. Solutions include checking the jumper and plugging it correctly, and setting the throttle channel's "TRIM" to 0 or its neutral position. If the car can't go forward but can go backward, the direction of the throttle channel might be incorrect, requiring users to reset it from "NOR" to "REV" or vice versa.

If the motor doesn't work but the LED in the ESC works normally, it points to broken connections between the motor and ESC, or a damaged motor. Solutions include checking connections, replacing defective connectors, or replacing the motor. If the motor suddenly stops running, it indicates a lost throttle signal, requiring users to check the transmitter, receiver, and throttle wire connection. If the car doesn't reach top speed and the red LED doesn't stay solid at full throttle, it could be due to activated low voltage or over-heat cut-off protection, or incorrect transmitter settings. Users should replace the battery pack, cool down the ESC, and set D/R, EPA, ATL to 100% or maximum value, and TRIM to 0 or neutral position.

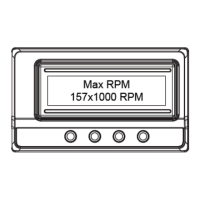

If the motor is cogging when accelerated quickly, it suggests the battery has limited discharge ability or the motor RPM is too high with an aggressive gear ratio. Solutions include using a battery with better discharge ability, or using a motor with lower RPM or a smaller pinion for a softer gear ratio. Finally, if there's something wrong with the car's driving system, users should check the driving system itself.

| Type | Brushed ESC |

|---|---|

| Continuous Current | 40A |

| Fan | No |

| Motor Type | Brushed |

| Input Voltage | 2S LiPo/6 Cells NiMH |

| BEC Output | 6V/3A |

| Motor Limit (2S LiPo/6 Cells NiMH) | 540 |

| Motor Limit (3S LiPo/9 Cells NiMH) | 540 |

| Applications | RC Cars, Trucks |

Loading...

Loading...