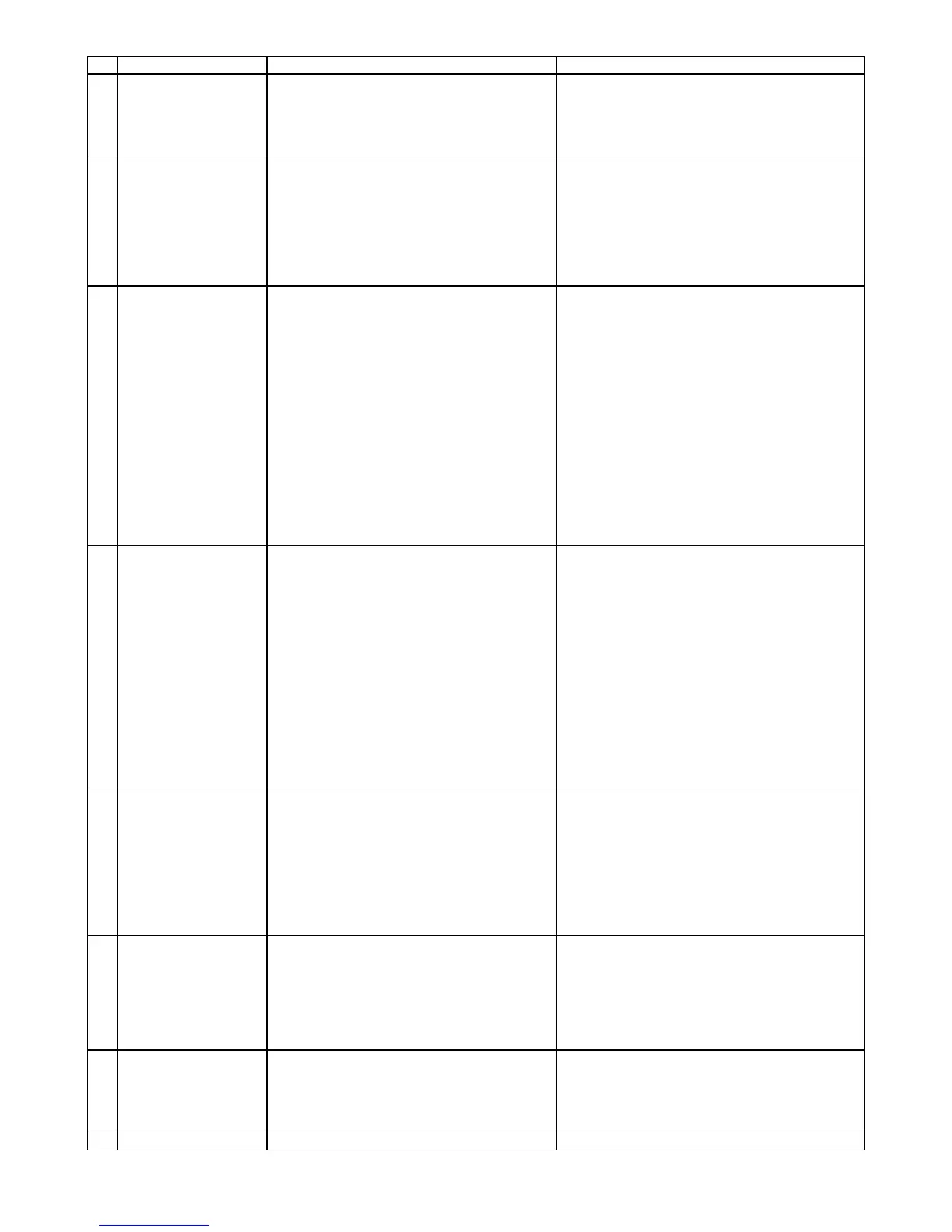

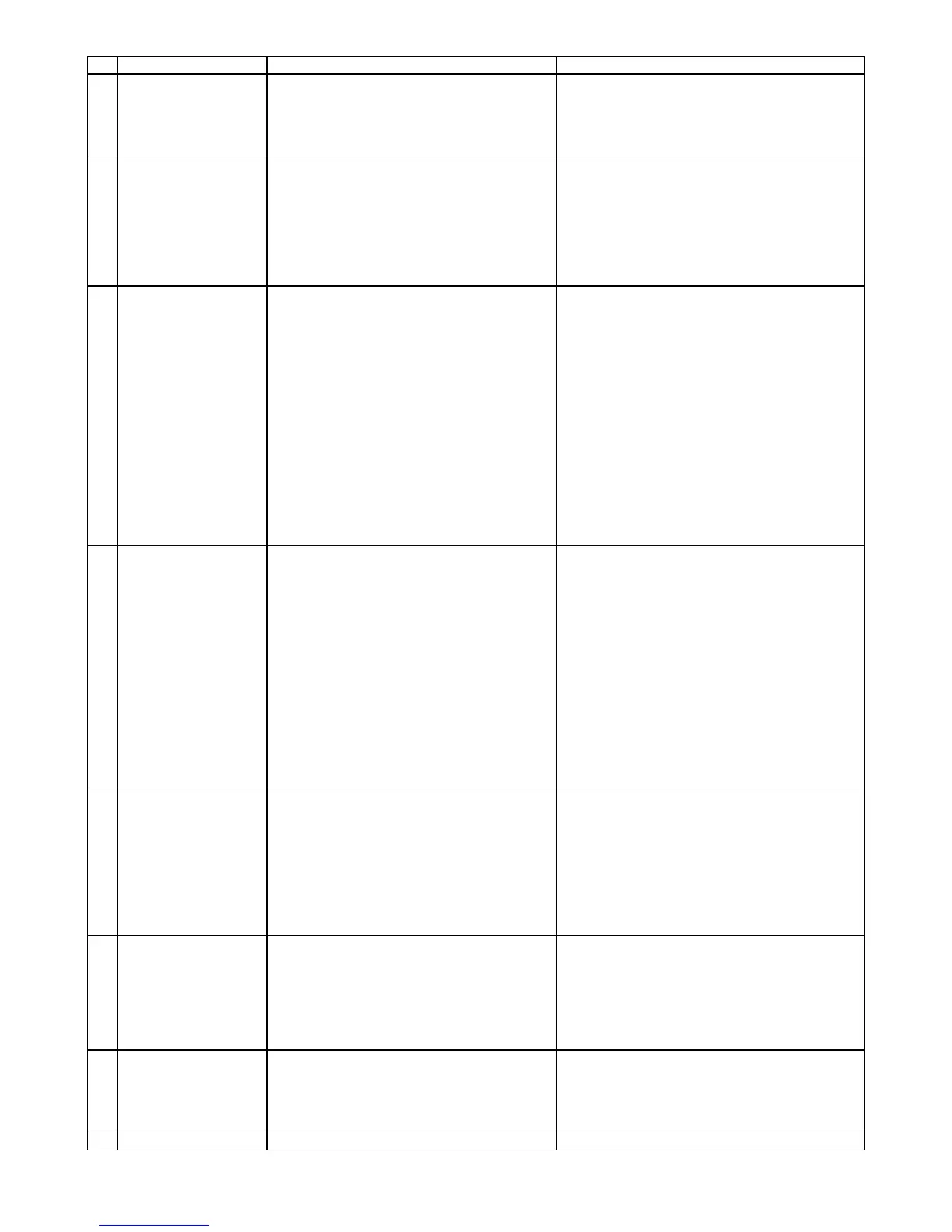

25

Electrical Connections Section 12.0

D

Injector flows fuel

wi

th ignition switch

in the “RUN” position

and engine not

running

- Poor Engine ground wire connection

- Leaky fuel injector

- Clean ground location and tighten

connection

- Replace fuel injector

E

“CLEAR FLOOD”

mode does not

operate while

cranking the engine

- Throttle does not open fully

- Faulty TPS

- Low voltage to ECU during cranking

- ECU does not supply 5 volt signal to TPS

- Check for interference between the throttle

linkage and surrounding components.

Adjust throttle linkage.

- Test TPS. See Testing the TPS section.

Replace TPS

- Ensure that voltage to ECU is above 8 volts

during cranking. Replace battery or starter

- Check all wire connections. Replace ECU

F

Engine Runs Rich - ECU adjustment knobs are set too high

- High supply fuel pressure

- High return fuel pressure

- Incorrect TPS adjustment

- Faulty TPS

- Oxygen sensor is mounted incorrectly

- Faulty oxygen sensor

- Leaking fuel injector

- Adjust knob settings. See Tuning section on

Page 22

- Install pressure gauges and adjust fuel

pressure. See Adjusting fuel pressure

section.

- Kinked or restricted fuel return line. Repair

kinks and remove obstructions from fuel

line.

- Adjust TPS position. See Adjusting the TPS

section on Page 21

- Test TPS. See Testing the TPS section.

Replace TPS

- See Optional Closed Loop System

installation section on Page 14

- Replace the oxygen sensor

- Replace fuel injector

G

Engine Runs Lean - ECU adjustment knobs are set too low

- Low supply fuel pressure

- Incorrect TPS adjustment

- Faulty TPS

- Restricted Fuel Injector

- Vacuum Leak

- Water in fuel

- Faulty oxygen sensor

- Adjust knob settings. See Tuning section on

Page 22

- Install pressure gauges and adjust fuel

pressure. See Adjusting Fuel Pressure

section.

- Adjust TPS position. See Adjusting the TPS

section on Page 21

- Test TPS. See Testing the TPS section.

Replace TPS

- Remove fuel injector and clean injector

screen and throttle body. Replace injector

- Locate vacuum leak and repair

- Remove water from fuel with proper fuel

additive.

- Replace the oxygen sensor

H

Hard Starting (Cold

Engine)

- “CHOKE” knob adjustment set too low

- Non-functional coolant temperature

sensor

- Non-functional fast idle solenoid

- Fuel pump not flowing fuel

- Increase “CHOKE” setting

- Test temperature sensor. See Testing the

Temperature Sensor section. Replace

sensor if necessary.

- Check wire connection to solenoid

- Test solenoid. See Testing the Fast Idle

Solenoid section. Replace solenoid if

necessary.

- See Item A

I

Hard Starting (Warm

Engine)

- Engine is flooding

- Non-functional coolant temperature

sensor

- Fuel pump not flowing fuel

- Use “CLEAR FLOOD” mode. Inspect

injectors after shutting off engine for injector

leakage. Replace leaking injectors

- Test temperature sensor. See Testing the

Temperature Sensor section. Replace

sensor if necessary.

- See Item A

J

Fuse blows

repeatedly

- Improper fuse installed

- Fuel pump motor is locked

- Wire insulation is broken resulting in a

short to ground

- Faulty ECU

- Install 10 Amp Fuse

- Test Fuel Pump. See Item A

- Inspect wiring harness and repair wire

- Replace ECU

K

Low Fuel Pressure - Low Voltage at fuel pump - Check voltage to pump from ECU. Inspect

Loading...

Loading...