26

- Kinked or restricted fuel line

- Faulty fuel pump

- Throttle body pressure regulator

improperly adjusted

- Low fuel level in tank

- Restrictive screen in tank

wiring harness. Check Battery voltage.

- Repair kinks and remove obstructions from

fuel line.

- See Item A

- See Adjusting Fuel Pressure section

- Add fuel to tank

- Clean fuel tank and increase screen size

L

High Fuel Pressure - Kinked or restricted fuel return line

- Return line diameter too small

- Throttle body pressure regulator

improperly adjusted

- Repair kinks and remove obstructions

from fuel line

- Replace fuel return line with larger

diameter fuel line.

- See Adjusting Fuel Pressure section

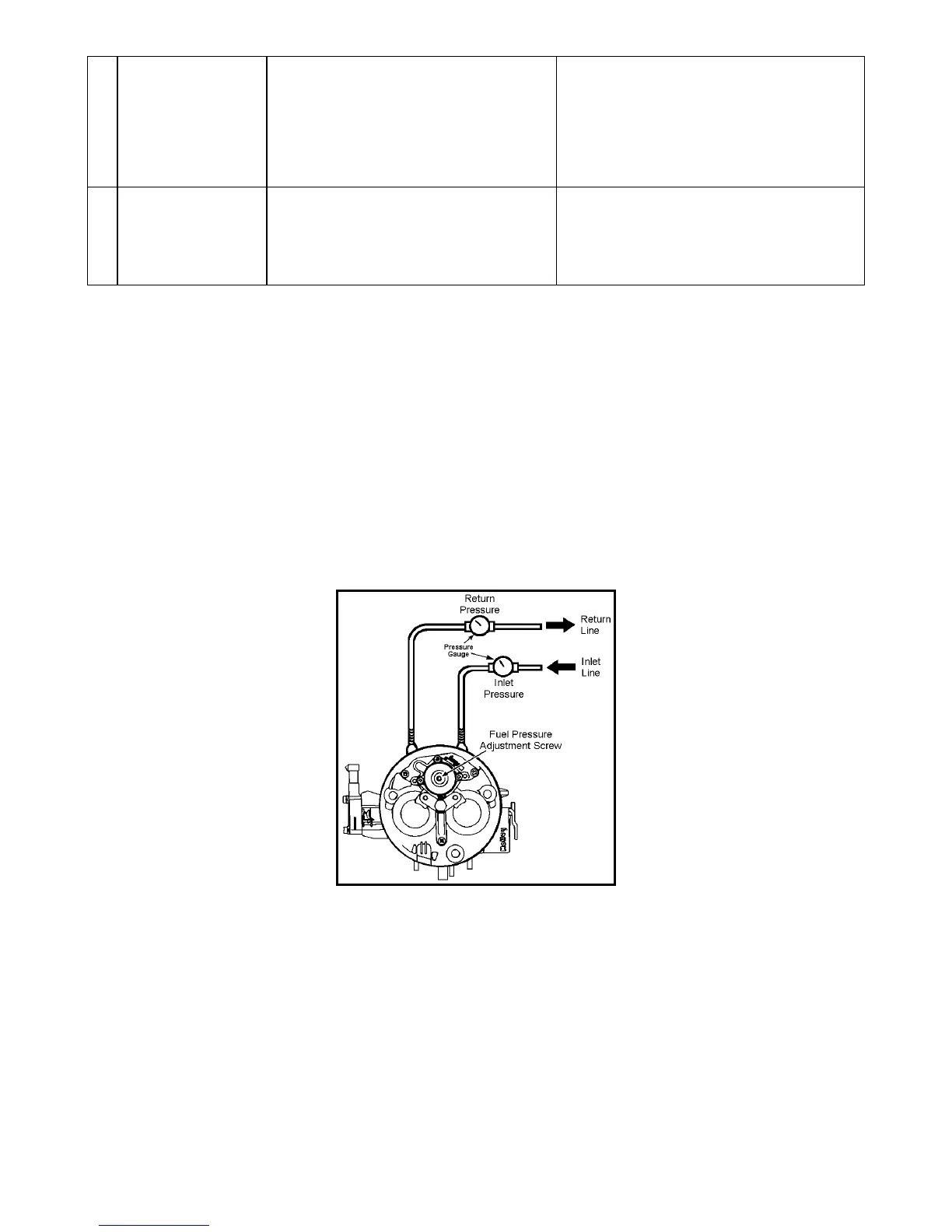

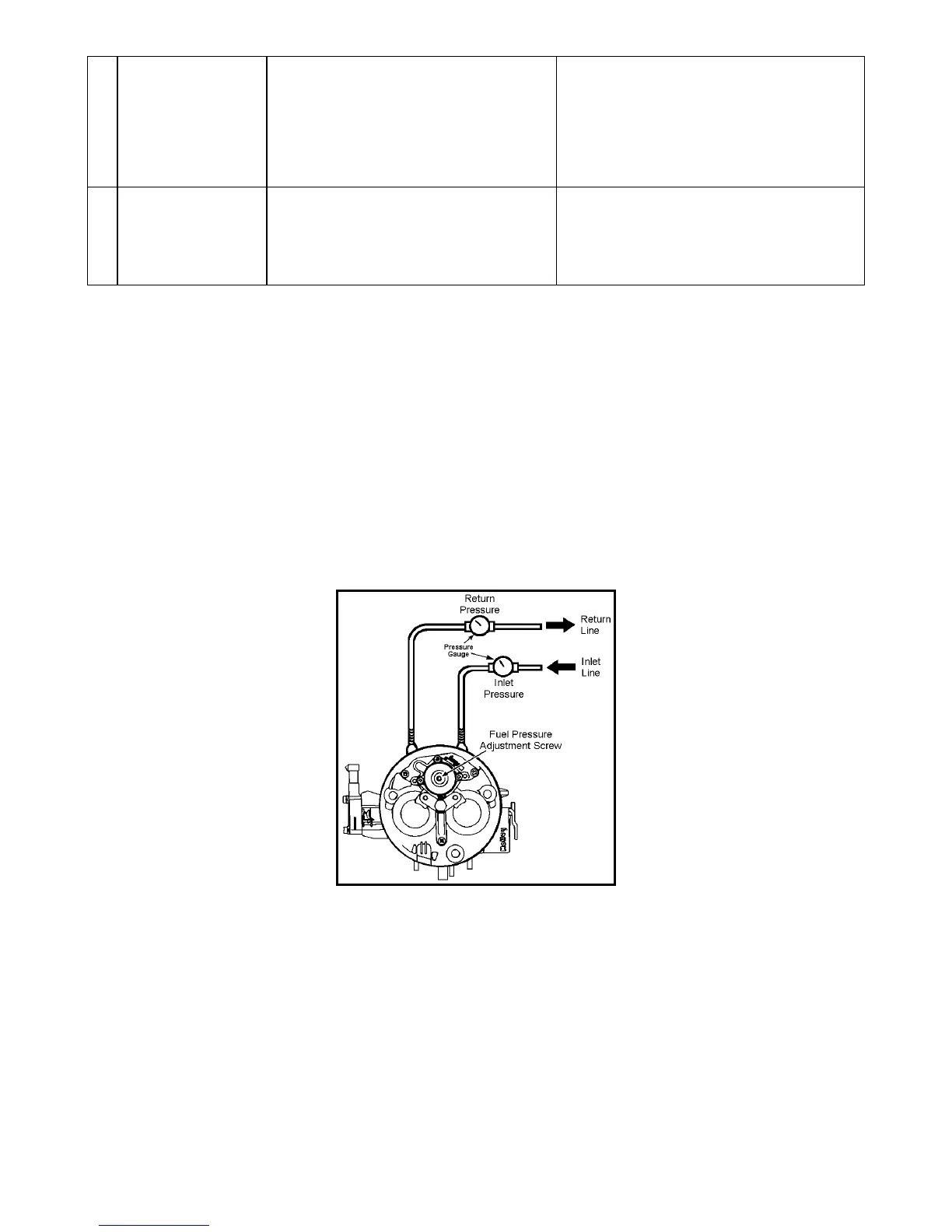

20.1 Adjusting the Fuel Pressure

The pressure regulator located at the rear of the throttle body is factory set at 15 PSI. A slight adjustment may be necessary to

allow for proper system operation.

1. Install a pressure gauge into the fuel supply line. This gauge must be removed after the fuel pressure has been properly

adjusted.

2. Start the engine and verify that the fuel lines do not leak. If any leaks are found, turn off the engine and repair the leaks

before continuing.

3. Insert a 5/32” Allen wrench into the pressure regulator screw on the top of the throttle body.

4. Turn the screw into the throttle body to increase the fuel supply pressure or out of the throttle body to decrease the fuel

supply pressure.

Figure 16

20.2 Testing the Coolant Temperature Sensor

The coolant temperature sensor used with the PRO-JECTION 2D system is a single wire sensor. The ECU supplies a fixed

voltage to the sensor. The resistance within the sensor varies with temperature and this variation in resistance is used by the

ECU to determine the engine’s coolant temperature.

Loading...

Loading...