SERIES-3000 VU52, VU53, VU54; VU442, VU443, VU444; VU842, VU843, VU844 FAN COIL VALVES AND ACTUATORS

95C-10885—01 4

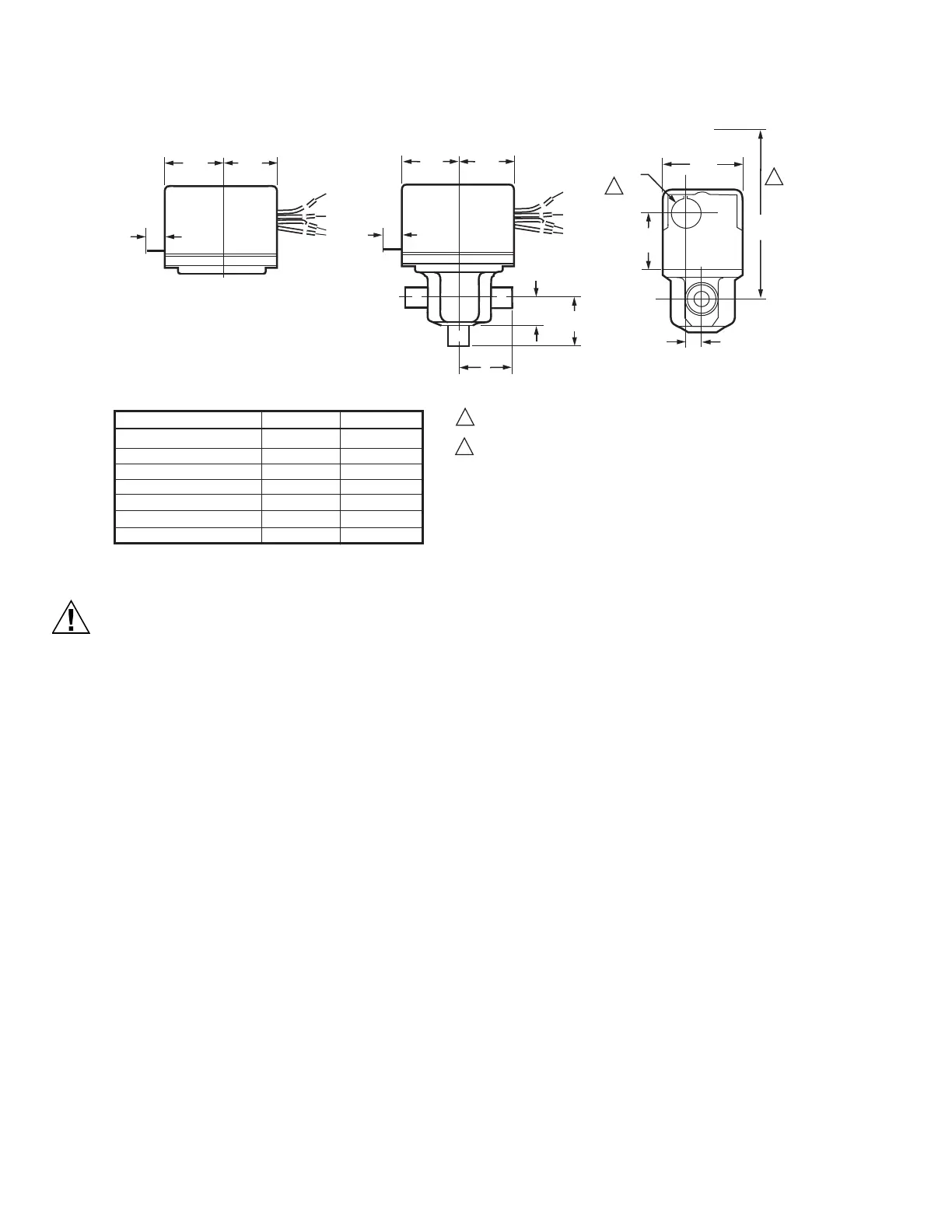

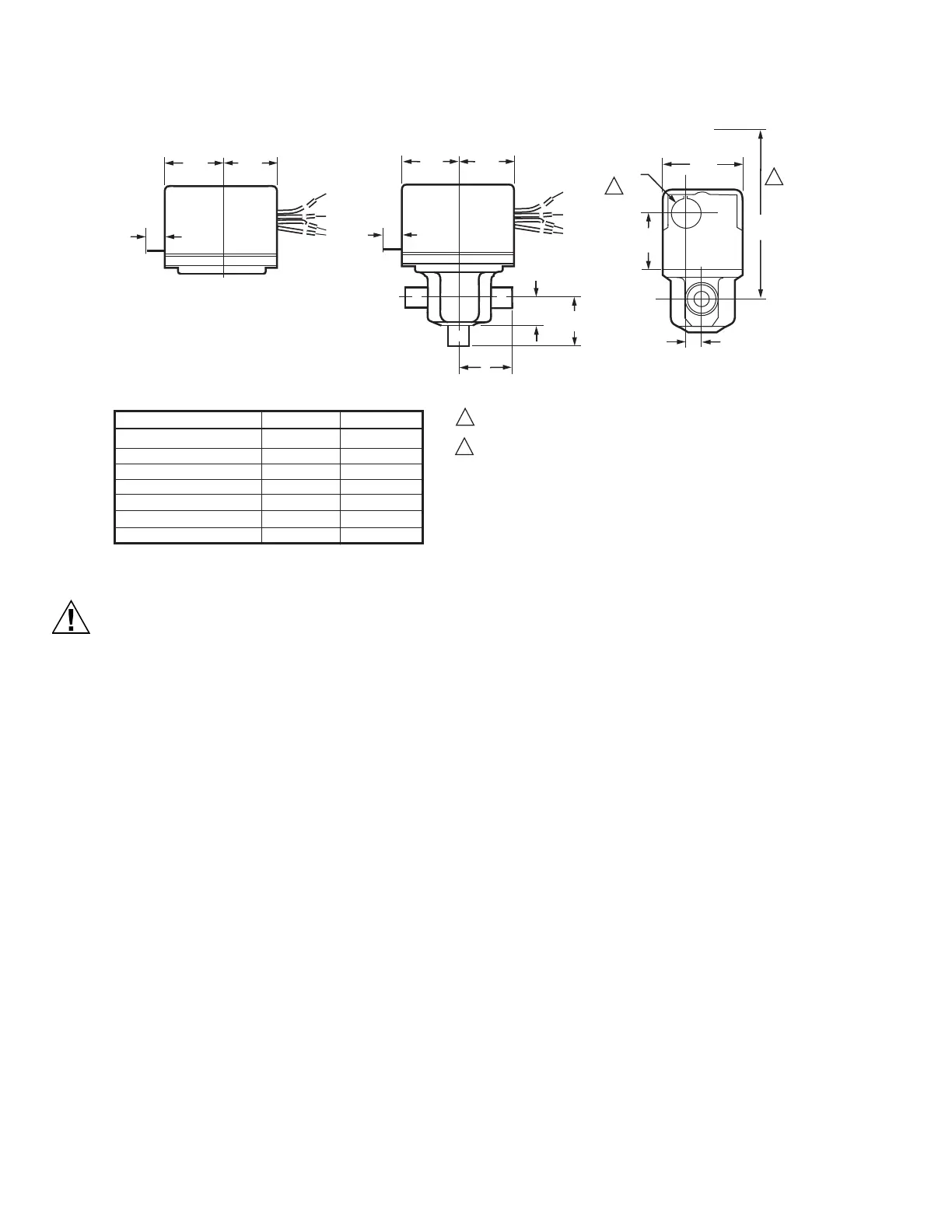

Fig. 1. Mounting Dimensions in in. (mm).

Equipment Damage Hazard

• Foreign particles like sand (quartz), rust, and

metal chips can damage the ball plugs.

• For trouble-free operation of the product, good

installation practice must include initial system

flushing, and chemical water treatment. Clean

the lines upstream of particles larger than 1/16

inch diameter (welding slag, pipe scale, sand

and other suspended particulate). Remove all Y-

strainer filters before flushing.

• Anti-freeze solutions that can be used, with

minimum 50% water dilution, are diethylene

glycol, ethylene glycol, and propylene glycol.

• Do not use boiler additives, solder flux and

wetted materials which are petroleum based or

contain mineral oil, hydrocarbons, or ethylene

glycol acetate. These chemicals can cause O-

rings and ball plug to swell and affect product

performance.

• If installing these valves in an addition to, or

retrofitting an existing building, do not assume

that the fluid in the existing piping meets these

criteria.

• When installing threaded fittings and pipes, if

tape is unavailable use minimum possible

amount of pipe dope. Excessive dope may be

forced into valve seat and interfere with valve

operation when pipe is assembled to body.

IMPORTANT

Hold valve by wrench flats ONLY when tightening

pipe fittings. Do NOT hold the valve body with the

pipe wrench: product damage may result.

1. Proceed with installation once the system specifics

(expansion/contraction of the system and its

medium as well as operating pressures) are within

tolerances.

2. Eliminate air from system.

3. Three-way valves may be installed for mixing or

diverting control.

4. Two-way valves are marked to show flow direction.

IMPORTANT

Flow arrows must point in the direction of the flow

for proper operation and to prevent water hammer.

How to Find Valve Pressure Drop

Valve pressure drop is determined by the formula:

ΔΡ = (gpm/C

v

)

2

x ρ

where ρ is the density of the glycol solution, and typically

ranges between 0.95 and 1.05.

The pressure drop in psi, or feet of water can be

determined from Fig. 2 as follows:

1. Calculate the flow rate to cool and dehumidify.

2. Determine the C

v

rating of the valve.

3. Select the graph corresponding to the C

v

rating of

the valve.

4. Determine the pressure drop across the valve using

the following procedures for calculating pressure

drop:

VU ACTUATOR

3/8

(10)

1-3/4

(44)

1-3/4

(44)

OPENING FOR 1/2 IN. CONDUIT ON OPPOSITE SITE OF

MANUAL LEVER FOR ALL MODELS.

HEIGHT NEEDED TO REMOVE ACTUATOR OR COVER.

VU53 VALVE WITH ACTUATOR

2-3/8

(60)

7/8 DIA.

(22)

1-1/2

(38)

3-3/4

(133)

15/32 (12)

VALVE BODY SIZE

A

B

3/8

(10)

1-3/4

(44)

1-3/4

(44)

7/8 (23)

2-WAY

B

3-WAY

A

A

2 1/8 (54)

(Inverted Flare)

VU52, VU53 AND VU54 VALVE DIMENSIONS WITH ACTUATOR

1

2

1

2

M32076

B

AB

A

1/2 IN. SWEAT 1-5/6 (33) 1-5/16 (33)

3/4 IN. SWEAT 1-3/8 (35) 1-11/16 (43)

1 IN. SWEAT 1-11/16 (43) 1-11/16 (43)

1/2 IN. F-NPT 1-3/8 (35) 1-5/16 (33)

3/4 IN. F-NPT 1-11/16 (43) 1-7/16 (37)

1 IN. F-NPT 1-11/16 (43) 1-7/16 (37)

1/2 IN. INVERTED FLARE 1-3/8 (25) 1-5/16 (33)

Loading...

Loading...