SERIES-3000 VU52, VU53, VU54; VU442, VU443, VU444; VU842, VU843, VU844 FAN COIL VALVES AND ACTUATORS

© 2021 Resideo Technologies, Inc. All rights reserved.

The Honeywell Home trademark is used under license from Honeywell International, Inc. This product is manufactured by Resideo Technologies, Inc. and its affiliates.

www.resideo.com

Resideo Technologies, Inc.

1985 Douglas Drive North, Golden Valley, MN 55422

1-800-468-1502

95C-10885—01 M.S. Rev. 08-21 | Printed in United States

Manual Operation

The 2-way normally closed and 3-way motorized valve

actuators can be opened manually, without power, by

lifting the manual opening lever over the stop and

pushing slowly and firmly to the MAN. OPEN position. The

stop permits the valve to be locked in the open position.

The valve returns to automatic position when it is

energized.

Normally Closed Models

With the manual opener set to AUTO and the actuator

energized, the A port is opened as shown in the powered

diagrams in Fig. 9 and 10. When the actuator is de-

energized, a spring-return mechanism drives the valve to

the port A closed position as shown in the unpowered

diagrams in Fig. 9 and 10. The valve can also be opened

with no electrical power by moving the manual opening

lever over the stop and pushing slowly and firmly to the

MAN. OPEN position. The stop permits the valve to be

locked in an open position. The valve returns to the

automatic position.

3-way valves may be installed as Normally Closed or

Normally Open by exchanging the orientation of the A and

B ports.

Normally Open 2-way Models

With the manual opener set to AUTO and the actuator

energized, the A port is closed as shown in the powered

diagrams in Fig. 9. When the actuator is de-energized, a

spring-return mechanism drives the valve off the port A as

shown in the “N.O. DE-ENERGIZED” position in Fig. 9 and

10. The manual opener is only used for installing or

removing the actuator from the body.

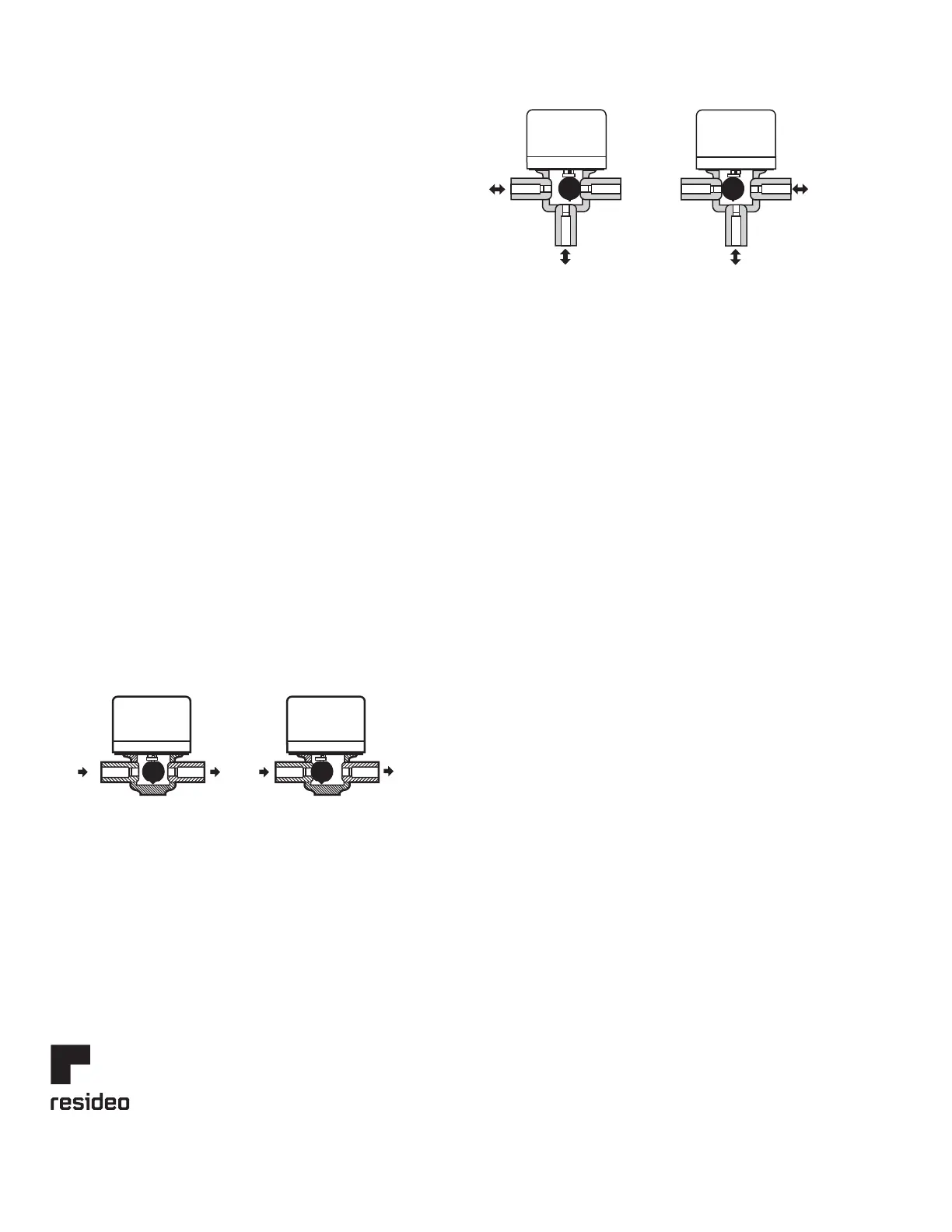

Fig. 9. VU842/442, VU843/443 Actuator operation for

2-way valve.

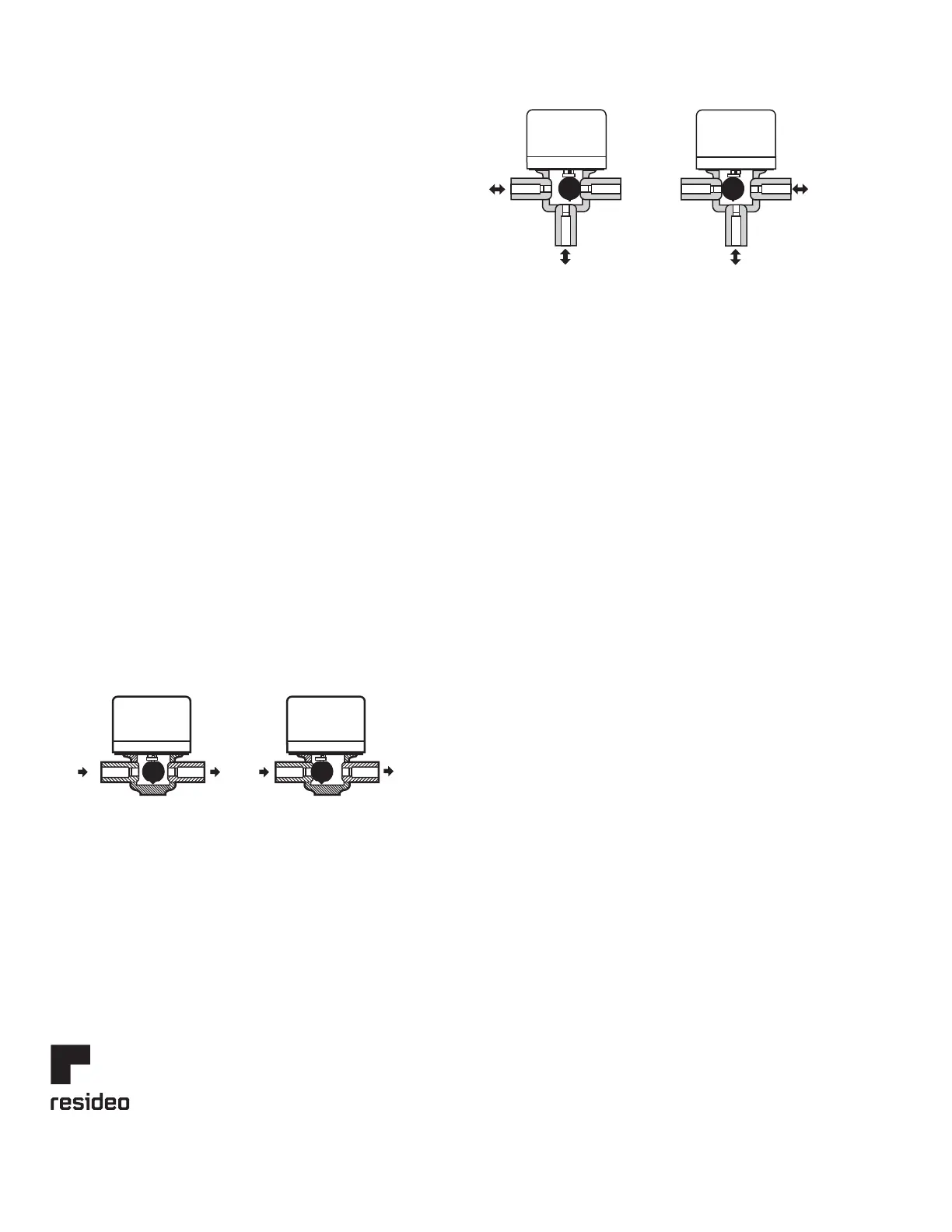

Fig. 10. VU844/444 Actuator operation for 3-way valve.

CHECKOUT

Set to heating mode

1. Raise the setpoint on the zone thermostat above the

room temperature to initiate a call for heat.

2. Observe all control devices—the valve should open.

3. Lower the setpoint on the zone thermostat below the

room temperature.

4. Observe the control devices. The valve should close.

Set to cooling mode

1. Lower the setpoint on the zone thermostat below the

room temperature to initiate a call for cooling.

2. Observe all control devices—the valve should open.

3. Raise the setpoint on the zone thermostat above the

room temperature.

4. Observe the control devices. The valve should close.

SERVICE

This valve should be serviced by a trained, experienced

service technician.

1. If the valve is leaking, drain the system and check to

see if the O-ring needs replacing.

2. If the gear train is damaged, replace the entire actu-

ator. See the Installation section. If the motor is

burned out, replace the motor.

NOTE: The fan coil valves are designed and tested for

silent operation in properly designed and

installed systems; however, water noises can

occur as a result of excessive water velocity or

piping noises can occur in high temperature

(higher than 212°F (100°C)) systems with insuffi-

cient water pressure. Valves are designed to be

cycled regularly. Product life may be shortened if

energized continuously for extended periods of

time.

B

OUT

OPEN POSITION

N.O. ACTUATOR DE-ENERGIZED

OR N.C. ACTUATOR POWERED

A

IN

B

OUT

CLOSED POSITION

N.O. ACTUATOR POWERED OR

N.C. ACTUATOR DE-ENERGIZED

A

IN

M5951

A

B

OUT/IN

FLOW-THROUGH SERVICE PORT

IN (MIXING)

OUT (DIVERING)

A

B

A

B

OUT/IN

IN (MIXING)

OUT (DIVERING)

A

B

FLOW-THROUGH BYPASS PORT

(UNPOWERED)

Fig. 12A

Fig. 12B

(POWERED)

M32084

Loading...

Loading...