CX Series

ISSUE 4 PK 88136

2. Turn cam wheel to be adjusted to desired

position. Each notch on the wheel represents a

change in operation point of 0,116 mm (.0045

in.). Moving the cam wheel in the direction away

from the base housing advances the operate

point. Pretravel decreases and overtravel

thereby increases. When positioning cams, be

sure the cam follower is allowed to utilize the full

rise of the cam. This is required to provide

adequate overtravel and release travel of the

basic switches.

IMPORTANT: Do not use the set screw in the

cam follower to adjust travel characteristics.

3. Release cam wheel.

4. Release cam follower.

To Adjust Rotary Types:

1. Lift cam follower.

2. Move cam wheel axially to disengage teeth on

wheel from teeth on shaft disc.

3. Turn cam wheel to desired position. Turning in

direction of shaft rotation advances operate

point. Pretravel decreases and overtravel

thereby increases. Each notch on the cam

wheel represents an operating point change of

7°20'. The symbols on the cam wheel simplify

changing rotation from clockwise to

counterclockwise to center neutral, or vise versa.

If the switch operates on clockwise and

counterclockwise rotation, the pointer on the cam

follower lines up with symbol

or symbol on

the cam wheel. When symbol

lines up,

pretravel of 15° max. is obtained. When symbol

lines up, 80° max., pretravel is obtained.

Operation is in the direction of the inclined

surface of the symbol when

or lines up with

the pointer on the cam follower.

4. When cam wheel has been rotated to desired

location, release cam wheel to engage with

mating shaft disc.

5. Release cam follower

CX Wiring Methods

Honeywell recommends that conduit be installed

per NEC articles 501-4 and 501-5.

REPLACEMENT PARTS

Replacement switch assemblies consist of the

components subject to mechanical or electrical

wear. They include basic switches, cam wheels,

cam followers, and springs. The assemblies are

factory adjusted to have the same operating

characteristics as new complete switches.

How to Order

Catalog listings for complete switches can be

converted to replacement switch assembly catalog

listings as follows:

Momentary action rotary or plunger actuated

switches with shaft or plunger restoring force: To

order a replacement assembly, change the first digit

in the catalog listing for a complete switch to 9 for

rotary switches or to 10 for plunger switches.

For example, the replacement switch assembly

for a 12CX5 rotary switch = 92CX5. The

replacement switch assembly for a 36CX2 plunger

switch = 106CX2.

Maintained action rotary switches without shaft

restoring force: To order a replacement assembly,

change the first digit to a 9 and drop the first digit

following the letters CX.

Example: 12CX12=92CX2

Printed circuit board (includes potentiometer)

for 4-20 mA current output CX switches: 15PA261-

CX.

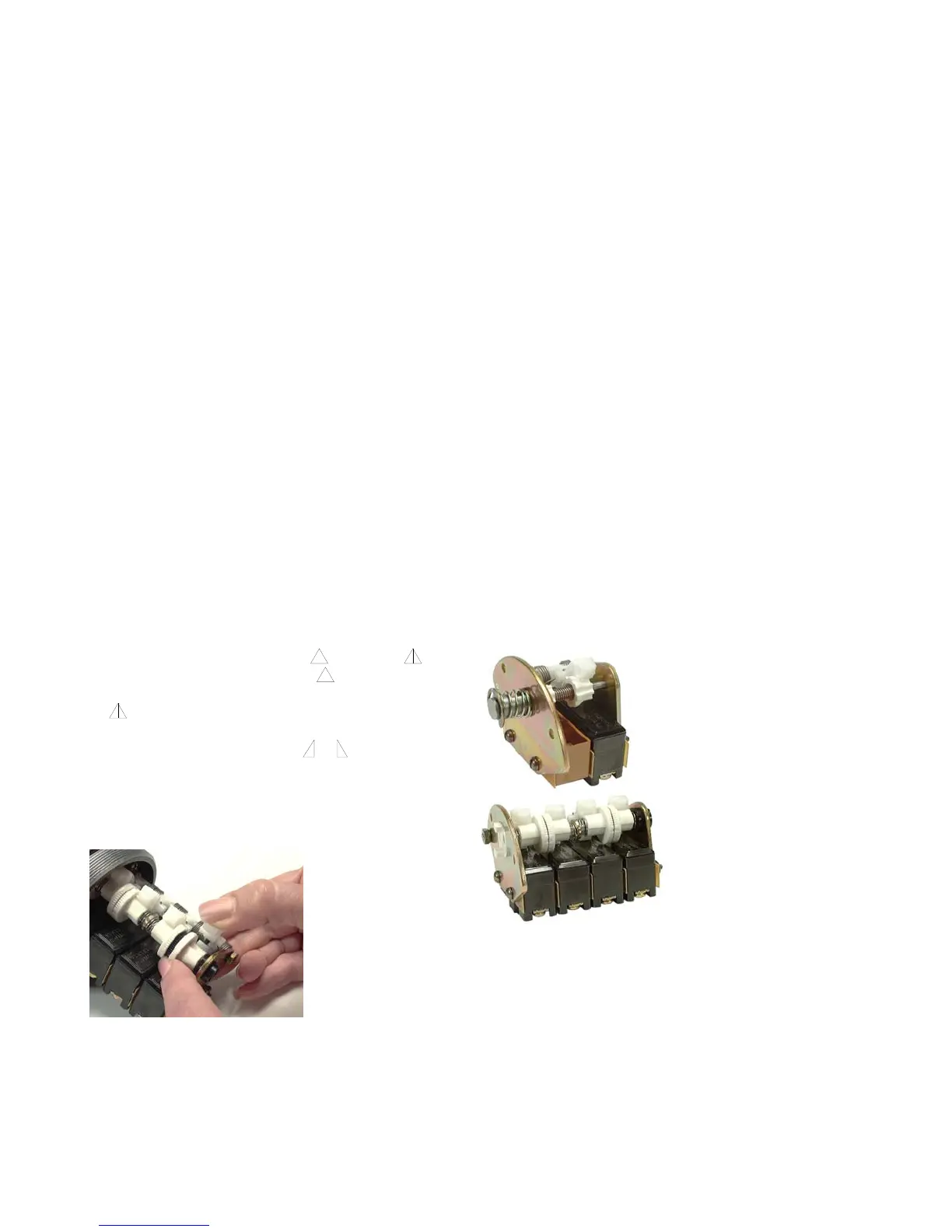

Plunger Switch

Assembly

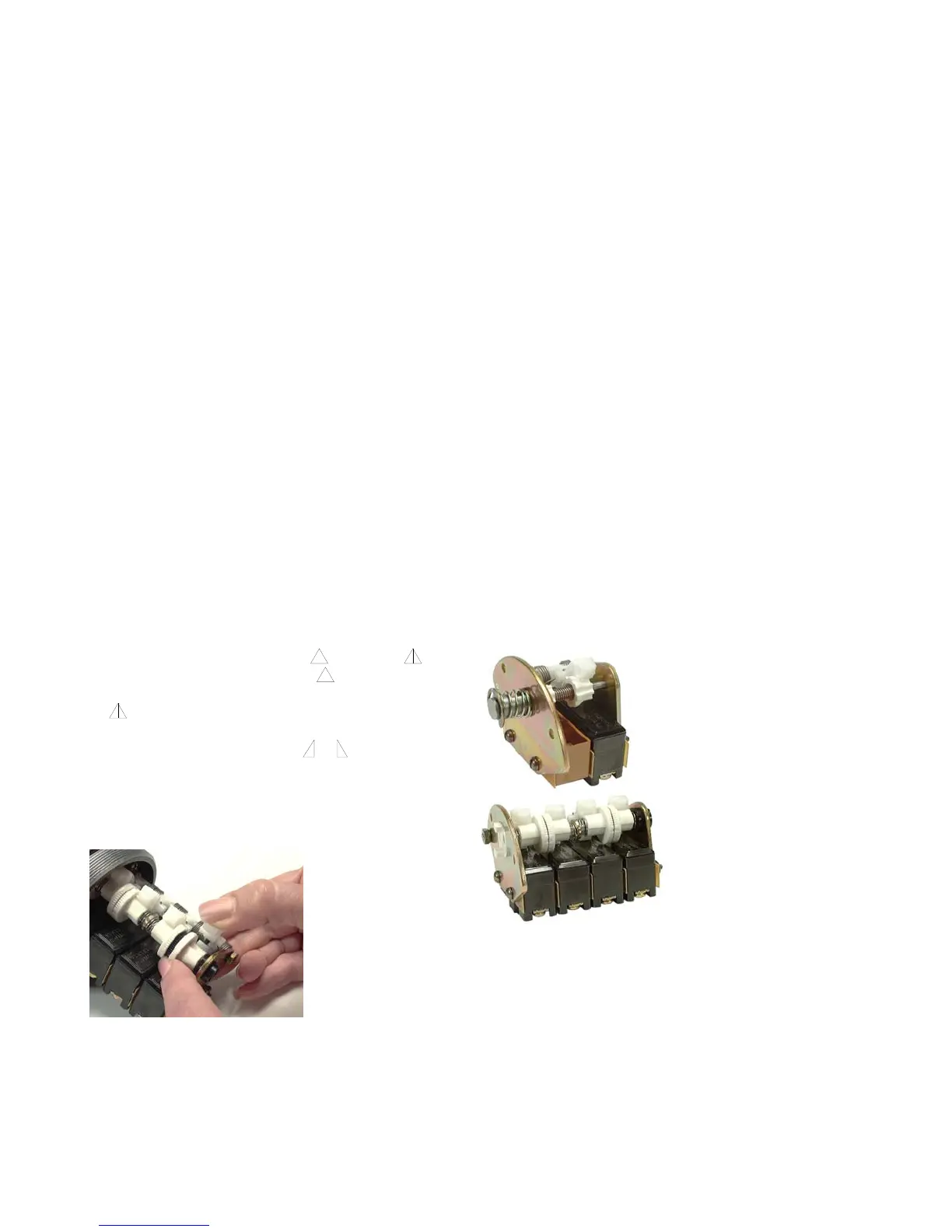

Rotary Switch

Assembly

2 Honeywell • Sensing and Control

Loading...

Loading...