Do you have a question about the Honeywell M9484 and is the answer not in the manual?

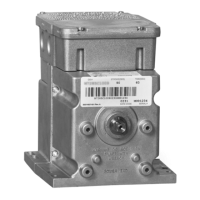

Introduces M9484/M9494 motors for burner control systems.

Highlights oil-immersed gearbox, NEMA 3 wiring, adjustable stroke, die-cast housing.

Explains model nomenclature and standard features like stroke adjustment.

Details voltage, current, power consumption, timing, and torque specs.

Covers load capacity, ambient temperature limits, and crankshaft specs.

Provides contact details for local sales offices and customer service.

Lists optional accessories like explosion-proof housing and linkages.

Details timing for 90°/160° strokes and breakaway torque.

General steps for installing the Modutrol IV motor.

Critical warnings for safe installation and operation.

Advises on suitable locations, avoiding corrosive/explosive atmospheres.

Details motor mounting, including crankshaft orientation.

Explains the purpose and mounting of the 220738A adapter bracket.

Guidance on connecting motor to damper linkages.

Specifies linkages needing adapter bracket for valve applications.

Covers wiring safety, transformer needs, and terminal connections.

Shows internal wiring schematics for the motor.

Identifies motor terminals and adjustment points like stroke potentiometers.

Explains wiring colors and connections for internal auxiliary switches.

Step-by-step guide for setting motor stroke (90° to 160°).

Illustrates the setup for adjusting motor stroke.

Illustrates the setup for adjusting auxiliary switch cams.

Explains motor operation with Series 90 controllers.

Detailed steps for setting auxiliary switches for desired differentials.

Shows wiring for Series 90 controllers.

Illustrates wiring for 4-20 mA control outputs.

Procedures to verify correct installation and operation.

Guides for replacing actuators with new motors.

Loading...

Loading...