24

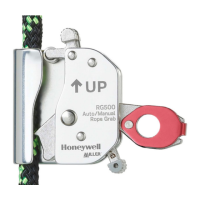

5.4 Inspection checklist (see Fig. 9)

Body (1.0)

• Body must be free from paint/mortar/concrete/dirt etc.

• Markings according to 5.1 are clearly legible

• Direction arrow (1.2) is easily recognizable

• Safety pin (1.3) is not bent and sits firmly

• Running surface (1.4) is clean

• Sliding parts (1.5) have to be in place

• Sliding parts (1.5) are not worn out

Shock absorber + Safety catch (2.0)

• Shock absorber + safety catch moves freely without any recognizable friction

• Shock absorber is not deformed (2.1) - max 57 mm

• Arrow heads of the fall indicator marking (2.2) close to the shock absorber eye are

aligned with each other

Wheels (3.0)

• All wheels are in place, 8 units

• Radial slackness: max 0,5mm

• Wheels rotate freely (concentrically)

• Wheels must not be damaged

• Wheels sit firmly on the axles

• Minimum outer diameter of the wheels (3.1) is at least 9 mm

Compression spring (4.0)

• Check by functional testing

• Is free from rust, dirt, concrete, paint etc.

• Spring is not deformed

• Spring is not broken

Swivel shackle (5.0)

• Swivel shackle moves freely

• Swivel shackle is not broken

• Swivel shackle has no cracks or other damage

• Thickness of the shackle (5.1) is at least 5,5 mm

• Riveting have to be secured

• External dimension of shackle pin eyelet (5.2) does not exceed 40 mm

Carabiner (6.0)

• Carabiner is not bent or broken!

• Carabiner has no cracks or other damage

• Carabiner gate (6.1) is not damaged

• Carabiner gate (6.1) should open easily

• Carabiner gate (6.1) closes and locks automatically after releasing by hand

• Locking pin (6.2) is in place

• Safety screw (6.3) must not be loose and sits firmly

EN

Loading...

Loading...