S9240F1004 MODULATING HOT SURFACE IGNITION INTEGRATED FURNACE CONTROL

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2007 Honeywell International Inc.

69-2088—01 M.S. 11-07

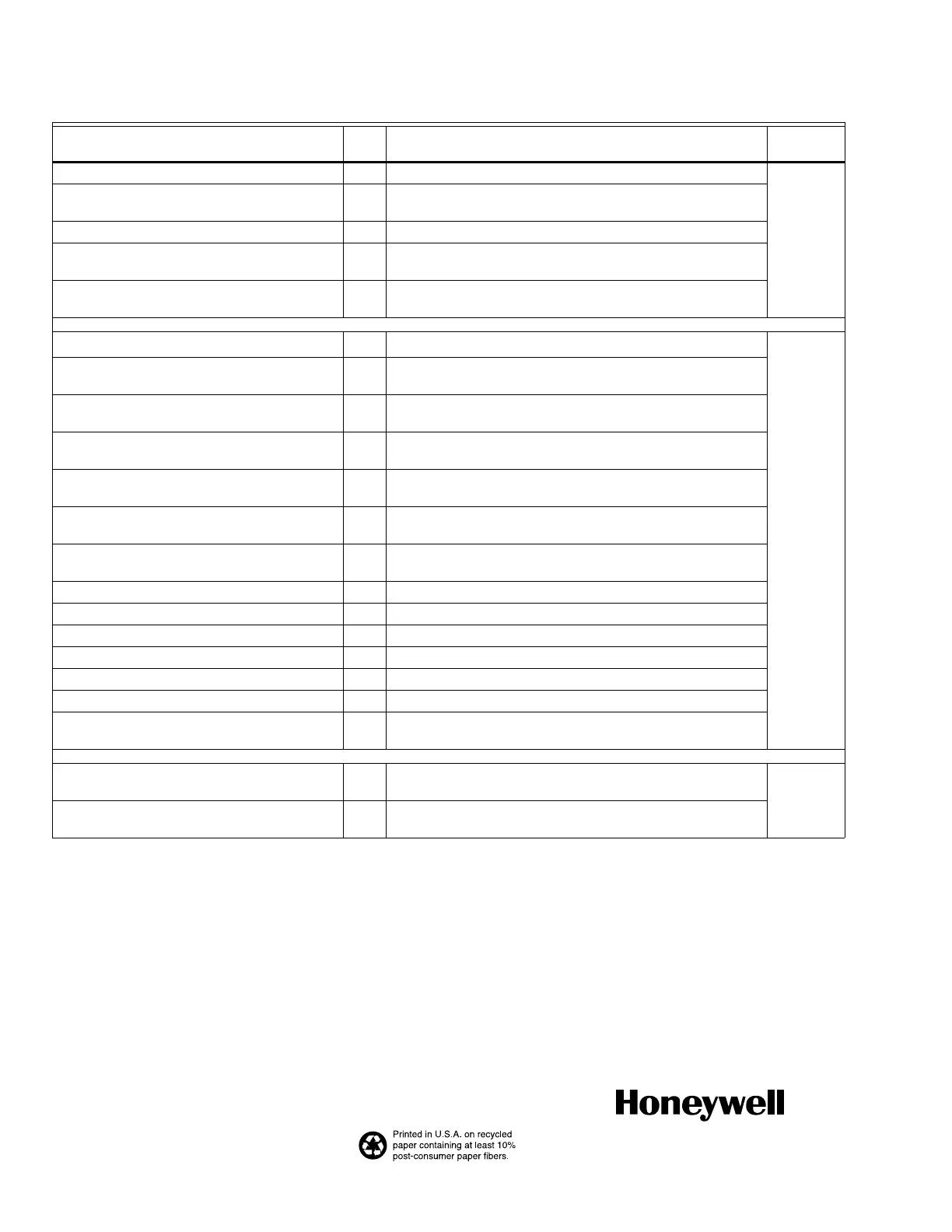

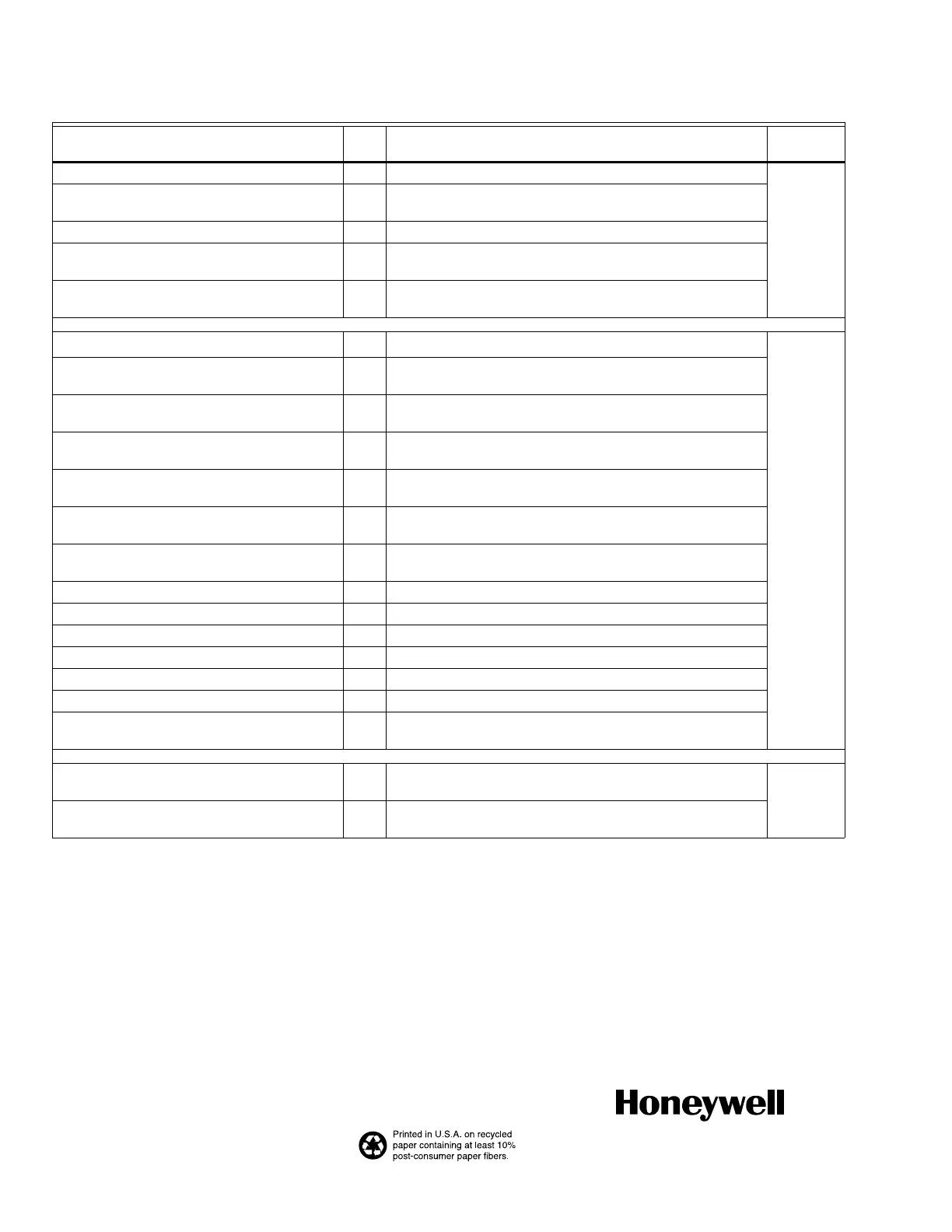

Low pressure switch failed (stuck) Closed 224 Resume normal operation after fault removed.

Wait for

Recovery

High pressure switch failed (stuck) Open 225 Increase inducer RPM every few seconds. If upper limit

reached, start pressure switch calibration.

High pressure switch failed (stuck) Closed 226 Wait for it to open, then start calibration.

Low pressure switch opened in run or Trial for

Ignition

227 Increment recycle/retry. Go to Soft Lockout if > maximum

Limit switch circuit open 250 Wait for Limit switch circuit to close. If closed in 3 minutes,

resume operation, else enter Soft Lockout after close.

Valve relay contact failure

125

a

Soft Lockout after fault recovers.

Soft

Lockout

Inducer/pressure switch calibration failure 228 Retry after 5 minutes. If failed allowed times, go to Soft

Lockout. Error counter cleared when exiting lockout.

Flame out of sequence while flame still

present

241 Wait for flame loss, then go to Soft Lockout. Error counter

cleared when exiting lockout.

Retry > maximum – last one due to no flame 270 Retry. If failed allowed times, go to Soft Lockout. Error

counter cleared when exiting lockout.

Retry > maximum – last one due to low

pressure switch open

271 Retry. If failed allowed times, go to Soft Lockout. Error

counter cleared when exiting lockout.

Recycle > maximum – last one due to low

pressure switch open

272 Retry. If failed allowed times, go to Soft Lockout. Error

counter cleared when exiting lockout.

Recycle > maximum – last one due to flame

lost in run mode

273 Retry. If failed allowed times, go to Soft Lockout. Error

counter cleared when exiting lockout.

Limit switch open > 3 minutes 274 Soft Lockout. Error counter cleared when exiting lockout.

Flame out of sequence and flame is gone 275 Soft Lockout. Error counter cleared when exiting lockout.

Failed ignitor or trigger circuit 290 Soft Lockout. Error counter cleared when exiting lockout.

Available CFM below minimum firing rate 291 Soft Lockout. Error counter cleared when exiting lockout.

Circulator unable to start 292 Soft Lockout. Error counter cleared when exiting lockout.

Circulator RPM out of range (failed wheel) 293 Soft Lockout. Error counter cleared when exiting lockout.

Inducer over current 294 Soft Lockout. Send command to reset-motor. Error counter

cleared when exiting lockout.

Rollout open or previously opened 200 Wait for rollout switch to close, then enter Hard Lockout. All

error counters cleared after reset.

Hard

Lockout

Furnace size select missing or mis-match with

installed circulator motor

202 Hard Lockout. All error counters cleared after reset.

a

Recycle furnace power and perform operational check. If error repeats, there may be a permanent failure on the control board.

Table 12. LED Status Codes. (Continued)

Error/Fault Condition Code

Error Handling

(in addition to displaying error code) Result

Loading...

Loading...