T775L SERIES 2000 ELECTRONIC STAND-ALONE STAGING CONTROLLER

11 62-0257—11

Setpoint High Limit

You can set an irreversible setpoint high limit maximum

value for any single displayed setpoint value.

Adjust the setpoint (at any output) to the desired

maximum setpoint. Then, simultaneously press the

HOME, , and buttons and continue to press all three

buttons for five seconds to set the setpoint high limit

maximum to this value.

NOTE: You must press all three buttons at exactly the

same time for this action to occur.

IMPORTANT

1. This action sets the maximum setpoint value of

all outputs to the setpoint high limit maximum.

2. Setting the high limit setpoint maximum is irre-

versible. If you perform the action inadvertently

and this setpoint adversely affects the control of

your system, you must replace the controller.

Staged Operation

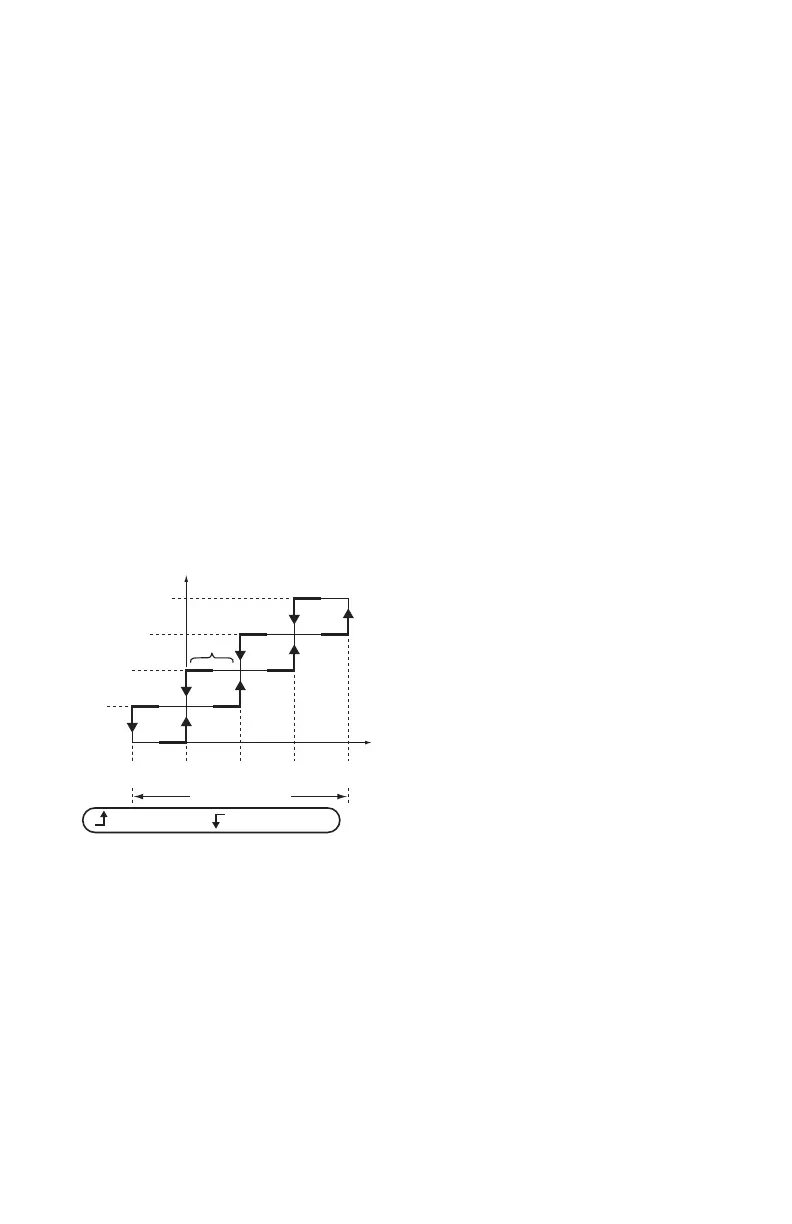

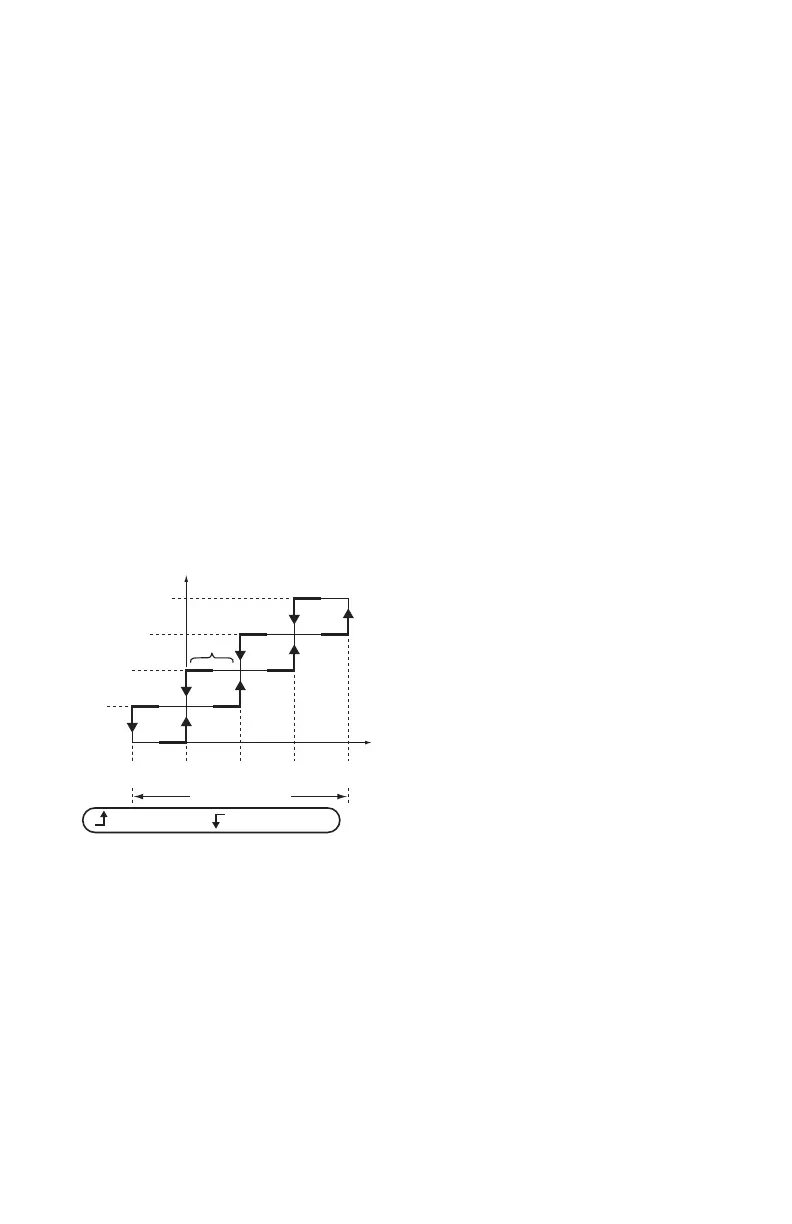

Staging occurs as illustrated in Fig. 18 for a Heat setpoint

of 200°F and a throttling range of 20°F when the Integral

value is zero (0). When the Integral is not zero, then the

actual temperatures at which stages energize and de-

energize will vary from this example; see “1.3.4.2.

INTEGRAL” on page 18.

NOTE: A non-zero integral causes the control to move

toward the setpoint value.

Fig. 18. Staging Behavior

(when effective Setpoint = 200°F).

Programming the T775L

Controller

In addition to the two staged loops, up to two additional

relays can be available for independent on-off control.

Examples of Loop and Relay configurations are:

• Number of relays = 8. Loop 1 uses relays 1-3, and

Loop 2 uses relays 4-6. The remaining two relays (7

and 8) are available for use.

• Number of relays = 11. Loop 1 uses relays 1-5, and

Loop 2 uses relays 6-10. The remaining relay (11) is

available for use.

• Number of relays = 12. Loop 1 uses relays 1-4, and

Loop 2 uses relays 5-8. Relays 9 and 10 are available

for use, but in this case, relays 11 and 12 are not

usable.

• Number of relays = 8. Loop 1 uses relays 1-6, and

Loop 2 uses relays 7-8. There are no additional relays

available for use.

IMPORTANT

If you change the number of relays, the control-

ler resets the number of relays per loop to zero

(0) for all loops. You must use Setup mode to

reconfigure all loops and additional relays. See

page 11.

To program the controller, perform the setup configuration

(see “1. Setup”) and then select one of the following

procedures depending on whether the Reset function is to

be used:

• Program the Outputs for No Reset — see

“2. Programming Output (Loops and Additional

Relays) with No Reset” on page 22.

• Program the Outputs for Reset — see “” on page 25.

When programming is complete, you may continue with

“4. Scheduling” on page 31.

1. SETUP

Setup provides the ability to change the factory default

settings for the temperature sensors and outputs, to

enable/disable reset control, and to enable/disable

scheduling.

IMPORTANT

If you change the number of relays, the control-

ler resets the number of relays per loop to zero

(0) for all loops. You must use Setup mode to

reconfigure all loops and additional relays.

NOTE: The T775L controller interface is intuitive. You

may want to use this procedure simply as a ref-

erence to locate the particular option or parame-

ter of interest.

NOTES:

1. If you press the HOME button or there is no

keypad activity for four minutes, you exit

Setup mode and return to the home screen.

2. If you press the MENU button, you exit Setup

mode and go to the Program menu.

Once in Setup mode, you use the —

• Left arrow button() to scroll backward through the

Setup menus

• Right arrow button () to select the highlighted menu

item and display its content

• Up and Down arrow buttons ( and ) to scroll up

and down through a list of items or to increase or

decrease the value of a displayed setup parameter

Setup Procedure

The Setup process uses a hierarchical menu structure

that is easy to use. You press the and arrow buttons

to move forward and backward through the menus.

NOTE: The menus can display only those relays that

are defined in Setup (see “1.3.1. Number of

RELAYS” on page 14). For example, if you con-

figure only two relays, then only two relays dis-

play on the appropriate menus.

M24297

THROTTLING RANGE

STAGE 2 ON

STAGE 3 ON

STAGE 1 ON

-25%

STAGES

HYST.

75%

205°F 185°F

0%

200°F

25%

195°F

STAGE 4 ON

50%

190°F

STAGE 1

STAGE 2

STAGE 3

STAGE 4

STAGE ENERGIZES STAGE DE-ENERGIZES

Loading...

Loading...