15

Operations

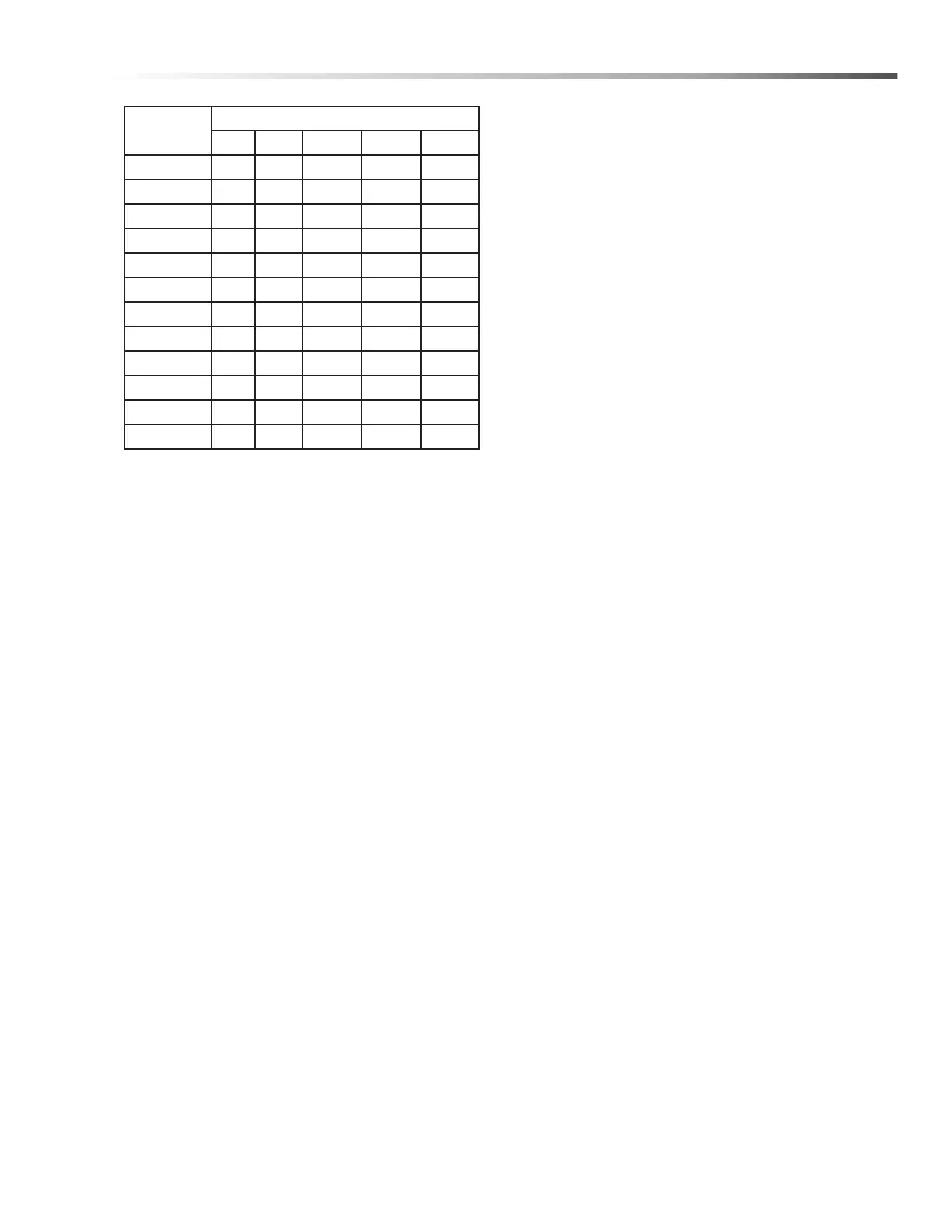

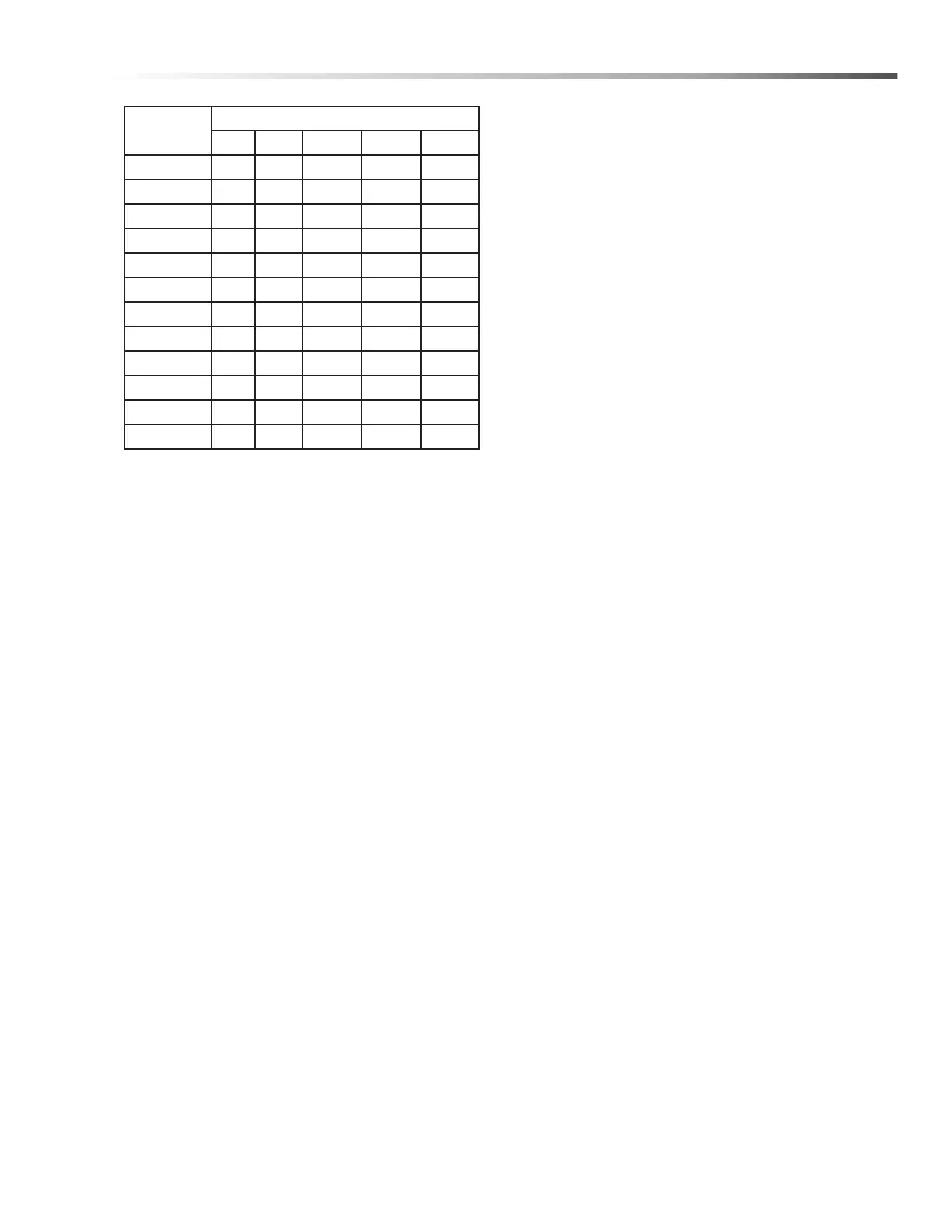

Maximum capacity of pipe in cubic feet/hr of

natural gas (Multiply values by 1000 to get nominal

BTU/hr capacity.

LP-Gas (Liquid petroleum gas or propane)

LP-gas is gas compressed into liquid form for easy

transportation and storage. It is also known as propane

or bottle gas. (Propane tanks are not supplied with this

equipment.)

LP-gas is flammable, is always contained under

pressure and the liquid can freeze skin. Therefore, in

the interest of safety, it is important to understand the

basic facts about LP-gas and LP-gas containers.

Federal DOT (Department of Transportation) regula-

tions require periodic inspections and re-qualifications

of cylinders. DO NOT USE damaged or rusted

containers.

DO NOT store LP-gas containers indoors or in

enclosed areas. Do not expose LP-gas container to

heat. Always store with service valve closed and

plugged as required.

CAUTION: Use LP-gas containers in proper

position.

ATTENTION: Utiliser des contenants de gaz de

pétrole liquéfié en position appropriée.

Most LP-gas pressure washer heaters are designed to

operate on LP-gas vapor only. Therefore, all LP-gas

containers designed for vapor service must be trans-

ported, installed and used in the proper position. Do not

transport, install or use a vertical cylinder in a horizontal

or upside down position. Proper care must be taken to

position a horizontal container in the correct position for

vapor withdrawal. Liquid LP-gas could enter the system

designed for vapor only, possibly creating a hazardous

condition.

Always use a POL plug installed on a POL valve or a

dust cap on an ACME/Type 1 valve when transporting

or storing disconnected containers (full or empty).

Check for leaks after connecting. Apply approved leak

detector solution to connection, turn off all burners and

pilots and open service valve. Leaks will be detected by

the growth of bubbles. If bubbles grow, tighten or repair

the connection as needed. Repeat leak test until

problem is corrected.

Check all tank and the line connections periodically to

be sure they are tight. When testing for leaks, use

approved leak detector solution — not matches.

Improved Regulation: The second stage regulator

receives a relatively uniform pressure from the first

stage regulator. This helps the second stage regulator

to maintain appliance pressure at a nearly constant 11"

W.C.

Filling the LP-Gas Container

Only qualified persons should fill your LP-gas

containers.

Les contenants de gaz de pétrole liquéfié doivent

être remplis uniquement par des personnes

qualifiées.

CAUTION: Overfilling is hazardous!

ATTENTION: Le remplissage excessif est

dangereux!

DO NOT allow your LP-gas container to be overfilled.

Stop filling when liquid appears at the fixed level gauge.

Bleed off excess propane in a safe area. Most LP-gas

containers are equipped with a fixed liquid level gauge

which contacts the liquid level at 80% of container

capacity, allowing 20% for expansion. LP-gas

containers not equipped with a fixed liquid level gauge

can only be filled by weight.

In cold climates, in order to keep vaporization of LP-gas

at the highest level, keep the fuel levels above 50%.

Combustion and Ventilation Air

Properly sized vents are vital for the safe and efficient

operation of a pressure washer installed in a confined

space. When combustion and ventilation air are

supplied from inside the building, each opening must

have an area of one square inch for every 1,000 BTUH

input. When combustion air is supplied from the

outside, each opening must have an area of one

square inch for every 2,000 BTUH for horizontal ducts

and one square inch for every 4,000 BTUH for vertical

ducts (refer to NFPA 54).

Hotsy 900/1400 Operator’s Manual 9.803-325.0 - C

Length of

Pipe (ft.)

Iron Pipe Size

3/4" 1" 1 -1/4" 1- 1/2" 2"

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

150 84 160 325 500 950

200 72 135 280 430 800

Loading...

Loading...