16

Operations

The purpose of venting a gas pressure washer is to

completely remove all products of combustion and to

vent gases to the outside air without condensation in

the vent or spillage at the draft hood (except in cases of

downdraft or poor stack conditions). To assure correct

venting, use a strong, gas-tight insulated pipe with a

cross section equal to that of the flue collar or draft

hood outlet and of sufficient vertical height.

During vent installation, avoid sharp turns, long hori-

zontal runs and improper pitches. Maintain proper

support of vent connectors and joints, observe clear-

ances from all combustibles and top the vent outlet with

an approved cap.

Type "B", due to its temperature rating, can only be

used with natural draft pressure washers. A "B" vent is

designed for exhaust temperatures not to exceed

470°F (245°C).

All venting installations must conform to local codes. In

the absence of local codes, refer to "National Fuel Gas

Code" NFPA 54 and be constructed of materials

approved by the Uniform Building Code.

Vents penetrating ceilings or walls should be double-

wall approved appliance vents and should be one to

two inches from combustibles. Vents passing through

enclosed spaces and vents exposed to the weather

should also be the double-wall type. Sometimes vents

have to be built of such great length that they come

apart at their joints under their own weight. These

should be screwed together at the joints with sheet

metal screws, usually three per joint. If the inspector

indicates that the vent is too close to combustibles, it

may be necessary to chisel away some of the combus-

tible or route the vent pipe around the combustible. The

cross-sectional area of any flue shall not be less that

the cross-sectional area of the flue vent connection

outlet of machine.

Ventilation

Water Source:

The water source for the machine should be supplied

by a 5/8" I.D. garden hose with a city water pressure of

not less than 30 PSI. If the water supply is inadequate,

or if the garden hose is kinked, the machine will run

very rough and the burner will not fire.

Water Connection:

Connect the high pressure hose by pulling the coupler

collar back and then inserting it onto the discharge

nipple. Secure it by pushing the collar forward.

Attach the wand into the spray gun using teflon tape on

the pipe threads to avoid leaks.

Inspection and Testing Gas Piping:

The building structure should not be weakened by

installing the gas piping. The piping should not be

supported by other piping, but should be firmly

supported with gas hooks, straps, bands or hangers.

Butt or lap welded pipe should not be run through or in

an air duct or clothes chute.

Before turning gas under pressure into piping, all

openings from which gas can escape should be closed.

Immediately after turning on gas, the system should be

checked for leaks. This can be done by watching the

1/2 cubic foot test dial for 5 minutes for any movement

or by soaping each pipe connection and watching for

bubbles. If a leak is found, make the necessary repairs

and repeat the above test.

Defective pipes or fittings should be replaced and not

repaired. Never use a flame or fire in any form to locate

gas leaks — use a soap solution.

After the piping and meter have been checked

completely, purge the system of air. DO NOT bleed the

air inside an enclosed room.

During pressure testing of the system at test pressures

in excess of 1/2 PSIG, the pressure washer and its indi-

vidual shut-off valve must be disconnected from gas

supply piping system or damage to the gas valve will

occur.

Hotsy 900/1400 Operator’s Manual 9.803-325.0 - C

Illustration showing air openings necessary

to supply air for combustion when installed

in an enclosed room.

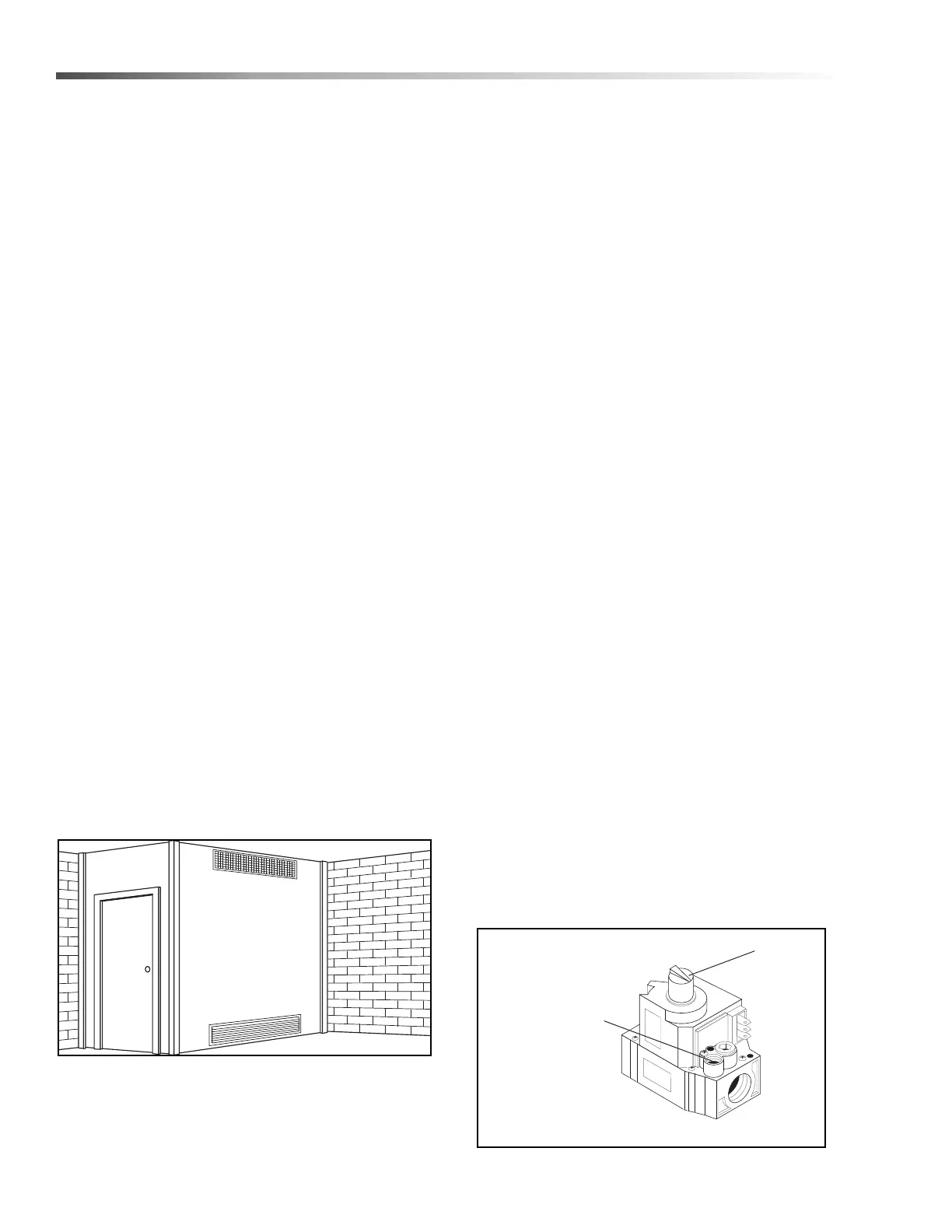

On/Off

Switch

Manifold

Pressure Adjustment

Screw Under Cap

Loading...

Loading...