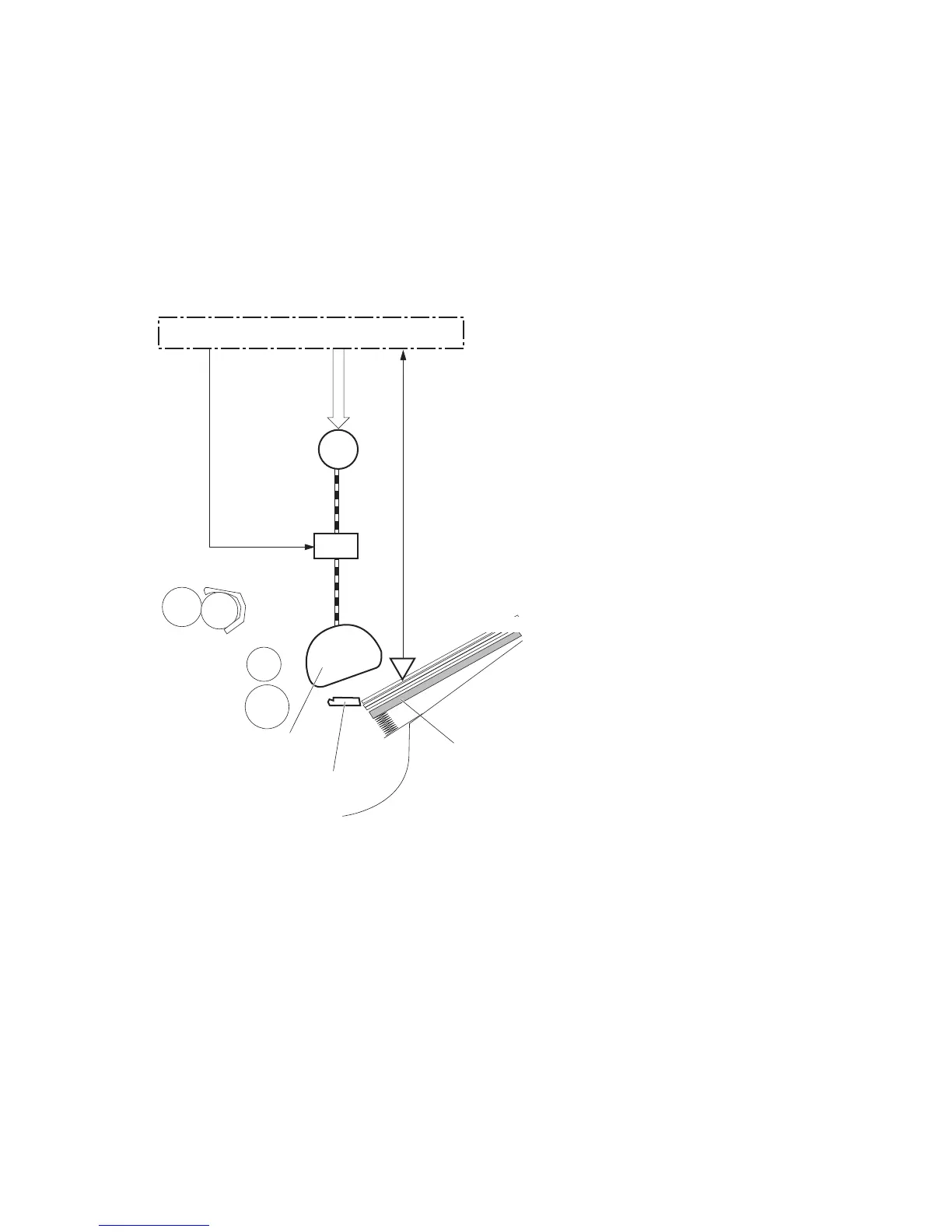

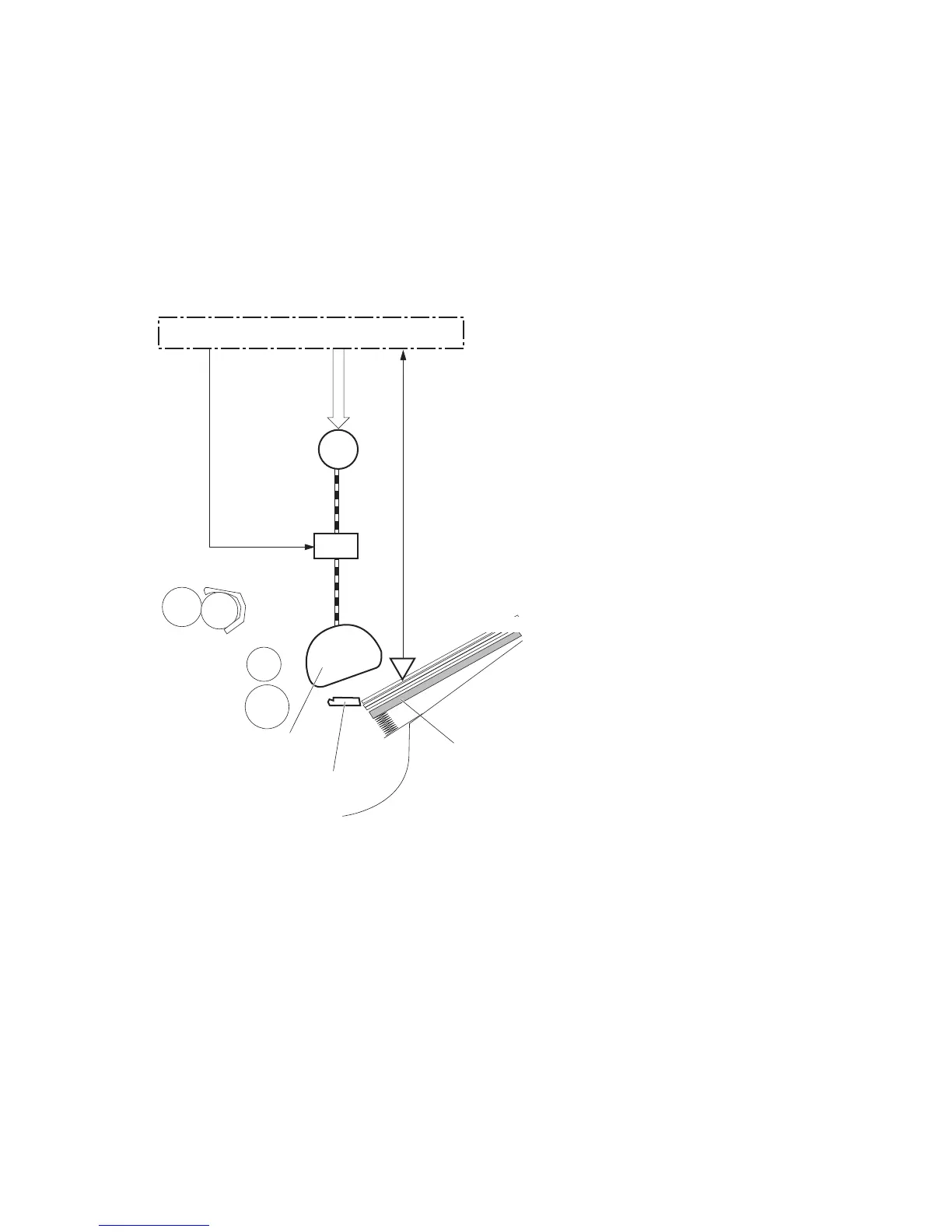

1. The pickup motor reverses when a print command is received from the formatter.

2. When the DC controller turns on the MP tray pickup solenoid, the MP tray pickup roller rotates and the

lifting plate lifts.

3. As the lifting plate rises, the paper is picked up.

4. The multipurpose tray separation pad removes any multiple-fed sheets, and one sheet is fed into the

product.

The MP-tray media-presence sensor (SR8) detects whether paper is present in the MP tray.

Figure 1-39 Multipurpose tray pickup mechanism

Lifting plate

MP tray pickup roller

MP tray separation pad

SL2

SR8

M13

Pickup motor

MP tray pickup solenoid

MP tray media presence sensor

DC controller

Paper feed

After the pickup operation, the paper feeds through the product and into the fuser.

1. The paper picked up from the cassette is fed to the registration unit as the pickup motor rotates. The

paper picked up from the multipurpose tray is fed to the registration unit as the pickup motor rotates.

The duplex model has the duplex feed clutch. The driving force of the pickup motor is transmitted to the

duplex re-pickup roller by turning on the clutch.

2. The registration shutter corrects the skew-feed.

3. When the TOP sensor detects the leading edge of paper, the DC controller stops the paper so that the

media sensor detects the type of paper.

4. The DC controller controls the rotational speed of the pickup motor to align the paper with the leading

edge of the toner image on the ITB.

52 Chapter 1 Theory of operation ENWW

Loading...

Loading...