Image Quality Service (Best and Normal)

This diagnostic helps you to check the performance of the printhead, and whether it suffers from clogging,

lack of ink in any color, or other problems.

This diagnostic is quite similar to the Diagnostic Print available in the user level, except that the image quality

level (best, normal) can be chosen.

Use a level of Image Quality similar to the settings of the prints with Image Quality problems.

Use the “normal” level to troubleshoot problems in normal and fast mode, and the “best” one for prints in

best mode.

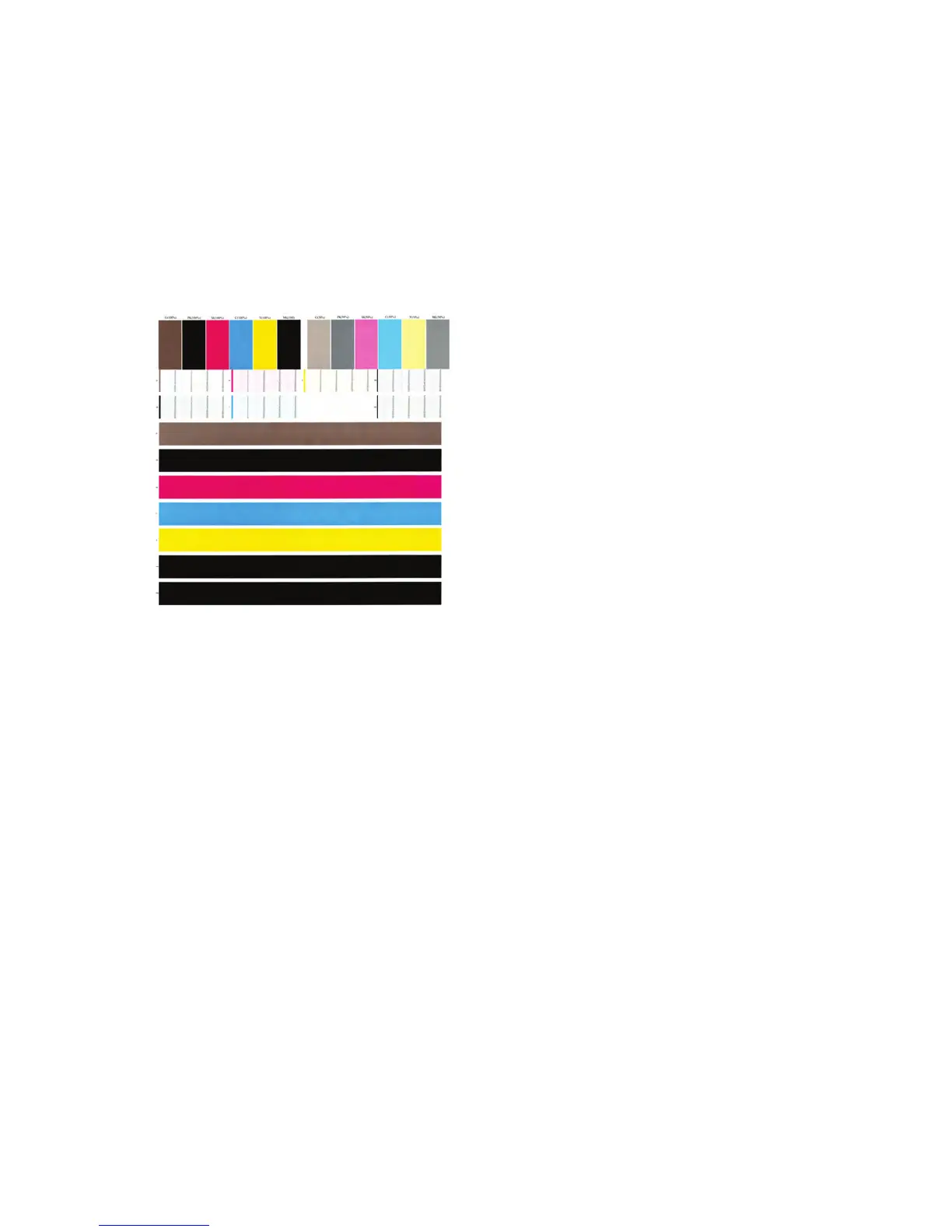

The print is divided into three parts:

●

Part 1 (top): consists of rectangles of pure colors at 100% and 50%; one for each ink. This part

represents the print quality that you will get from each color in the selected level of quality (best or

normal).

●

Part 2 (mid) : consists of small dashes; one for each printhead nozzle. This part complements the first,

and aims more specifically to detect how many faulty nozzles each printhead has.

Please look carefully at the print. The names of the colors are shown above the rectangles and to the left of

the patterns of dashes.

Before printing this image, perform a Force Drop Detection action (available on the Advance Diagnostic Print

Menu), in order to update the status of faulty nozzles, and print the printhead nozzle health more accurately.

First look at the upper part of the print (part 1). Each colored rectangle should be a uniform color without any

horizontal lines.

Then look at the bottom part of the print (part 2). For each individual colored pattern, check that most of the

dashes are present.

If you see horizontal lines in part 1, and also missing dashes in part 2 (same color), you should clean the

printhead, selecting the relevant color group. If the rectangles look solid, do not worry about just a few

missing dashes in part 2; these are acceptable as the printer can compensate for a few clogged nozzles.

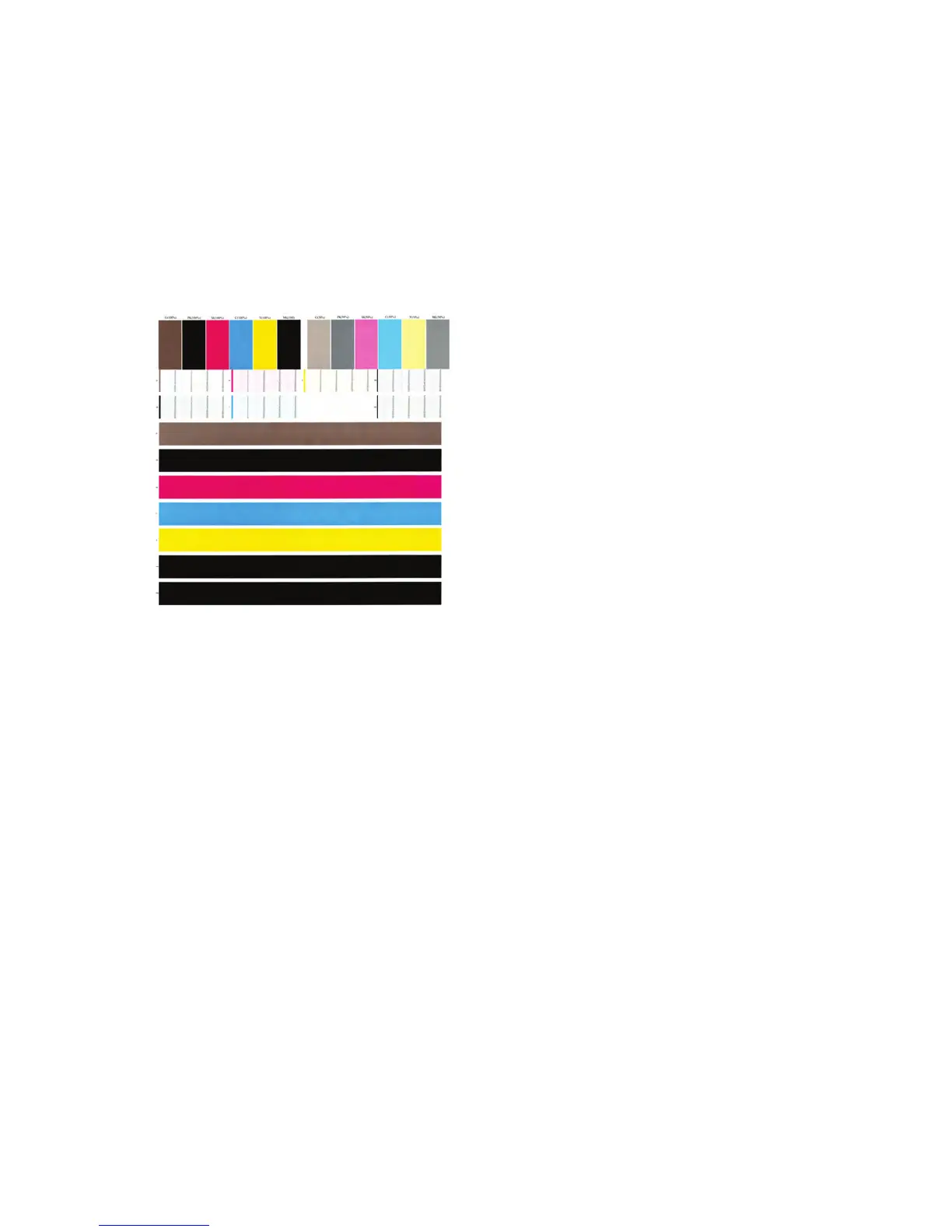

●

Part 3 (bottom): consists on several bars from side to side of the print, one for each ink. The aim of this

part is to detect a high number of consecutive faulty nozzles during continuous printing (for example

caused by air ingestion or lack of ink in the printhead).

186 Chapter 4 Diagnostics, Service Utilities and Calibrations ENWW

Loading...

Loading...