●

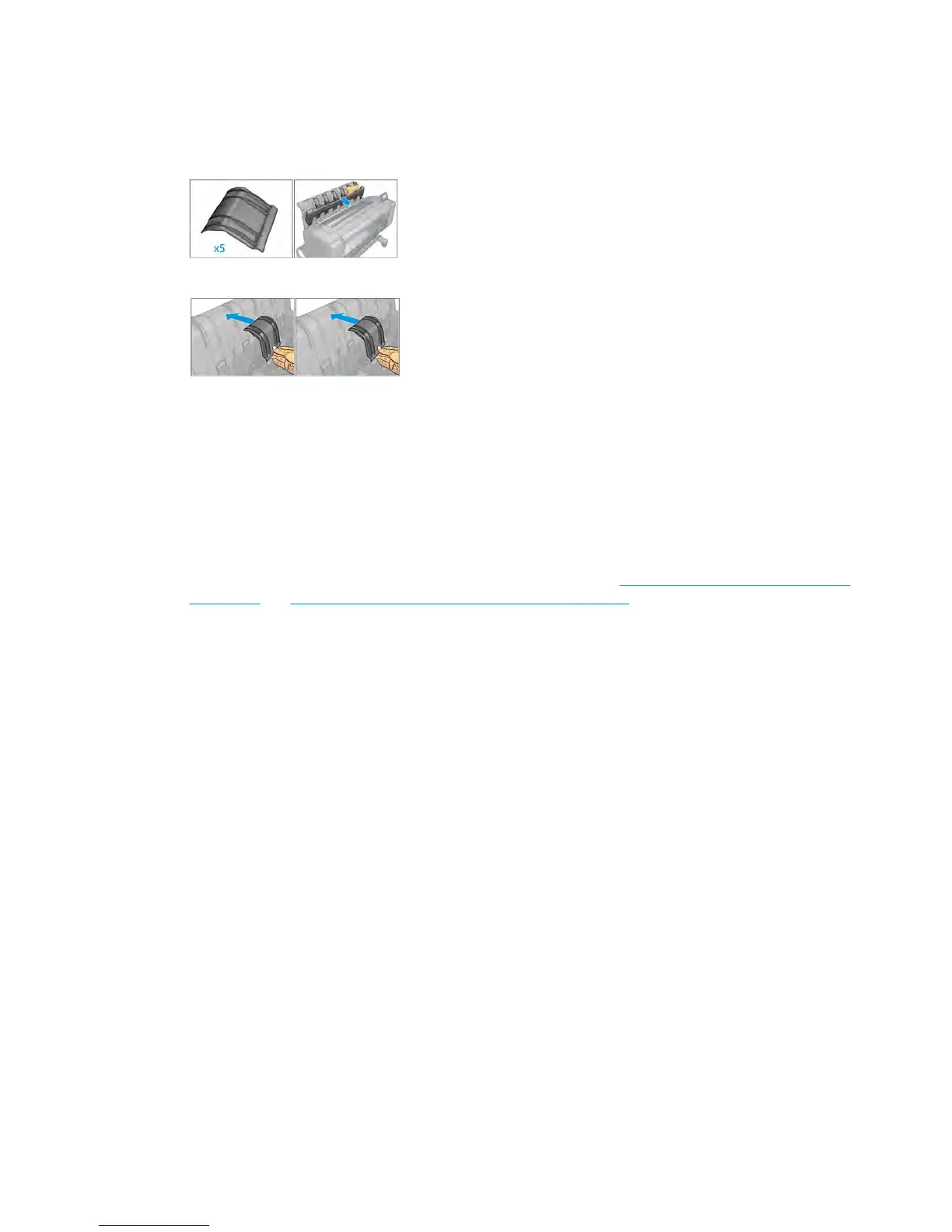

Use the CR357-67089 “Stacker tray filler” (CSR)

To improve the performance of the stacker when printing high density graphic content customers can

use the “Stacker tray filler” that guides stacker paper exit.

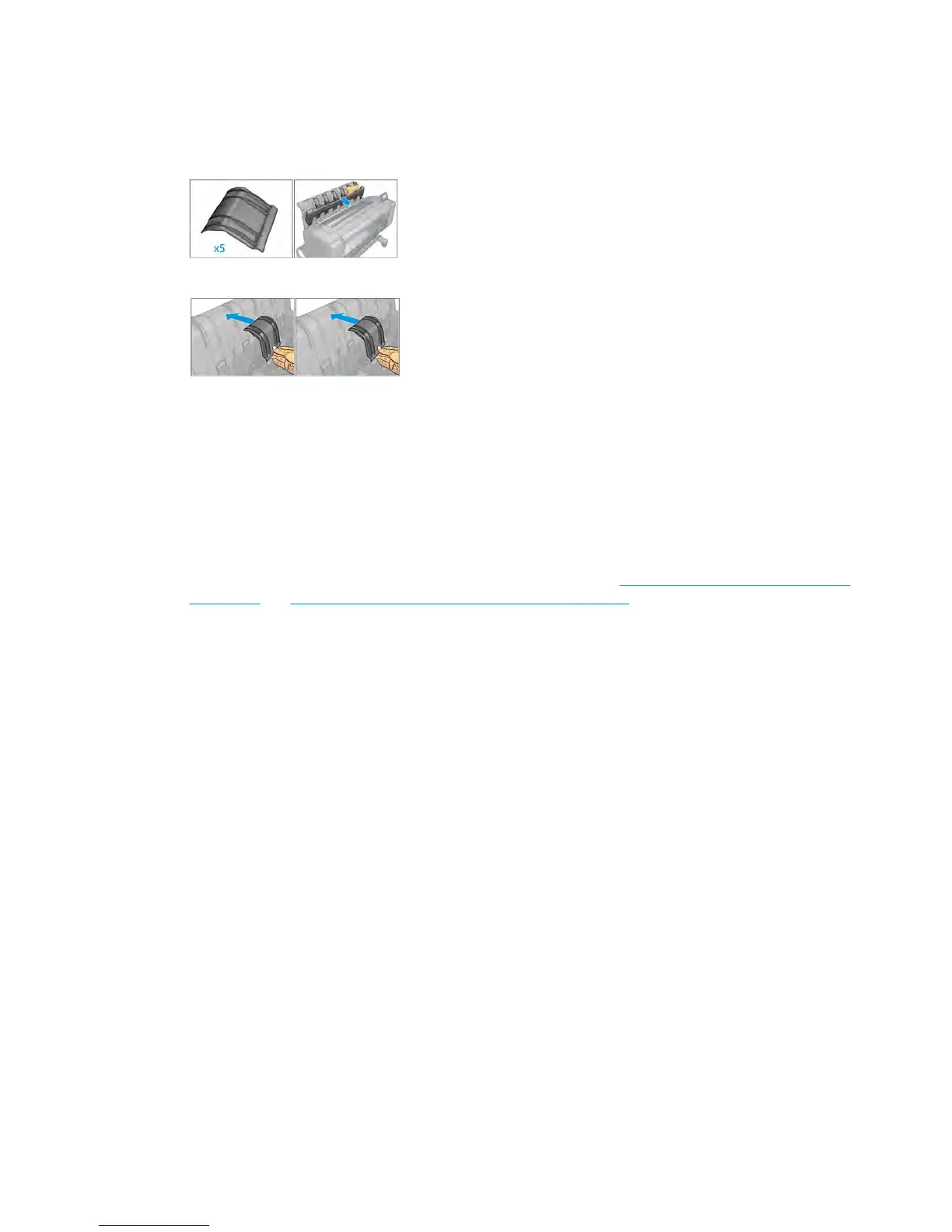

Place the parts of the Stacker tray filler as illustrated below:

Several stacker paper jams

Call agent:

1. Ask customer for Media type used and plot content.

2. Ask customer to check there is free space between top of the stacker and the wall.

3. Ask customer to check if one or several wheels of the arms cover is stuck in the paper path.

4. Exclude the cause to be any of the previously described issues. See Thin paper is jamming in the stacker

on page 52 and High density plots jamming in the stacker on page 53.

A root cause can be one or several wheels of the arm cover stuck in the paper path.

Ask the customer to perform the following actions:

5. Check that no cable routing is blocking the paper path.

6. Remove all paper from the stacker.

7. Detach the stacker arms cover from the printer.

8. Visually check that there are no missing wheel supports in the stacker cover (there are 25 wheel

supports).

9. Shake the stacker cover a couple of times so all the wheel supports can move freely.

10. Ensure that all wheel supports in the cover can rotate freely (by pushing them, and checking that they

return to their position). If any of them are stuck, try to move slightly to free them.

11. If any of the wheel supports are stuck or are missing, send a new stacker arms cover to the customer.

12. If all the wheel supports are free and there are none missing, then arrange an on-site visit with a new

stacker and stacker cover arms.

Service engineer:

Items required:

Take a stacker

Take stacker cover arms

54 Chapter 2 Troubleshooting ENWW

Loading...

Loading...