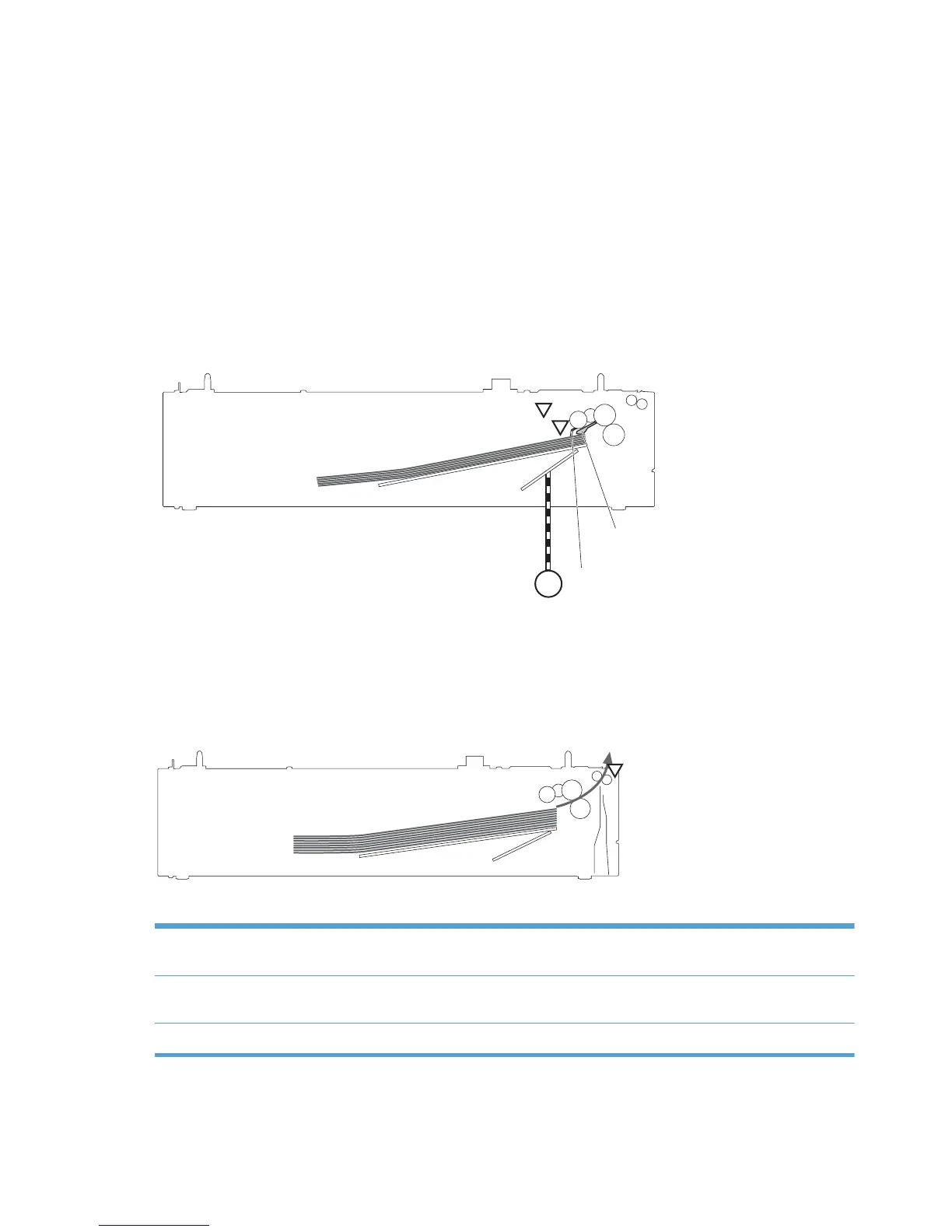

The operational sequence of the cassette lift-up is as follows:

1. The PF lifter motor rotates to raise the lifter.

2. When the PF paper-stack surface sensor detects the surface of the paper stack, the PF lifter motor

stops.

3. The lifter motor rotates again when the PF paper-stack surface detects that the paper surface is

lowered during a print operation.

The paper feeder controller PCA determines a PF lifter motor failure and notifies the formatter through

the DC controller when the PF paper-stack surface sensor does not detect the stack surface within a

specified period after the PF lifter motor starts rotating.

Figure 1-63 1x500-sheet paper feeder cassette lift operation

M2

SR2

SR3

Lifter

Lifting plate

PF lifter motor

PF media stack surface flag

PF cassette media presence sensor flag

PF media stack surface sensor

PF cassette media-out sensor

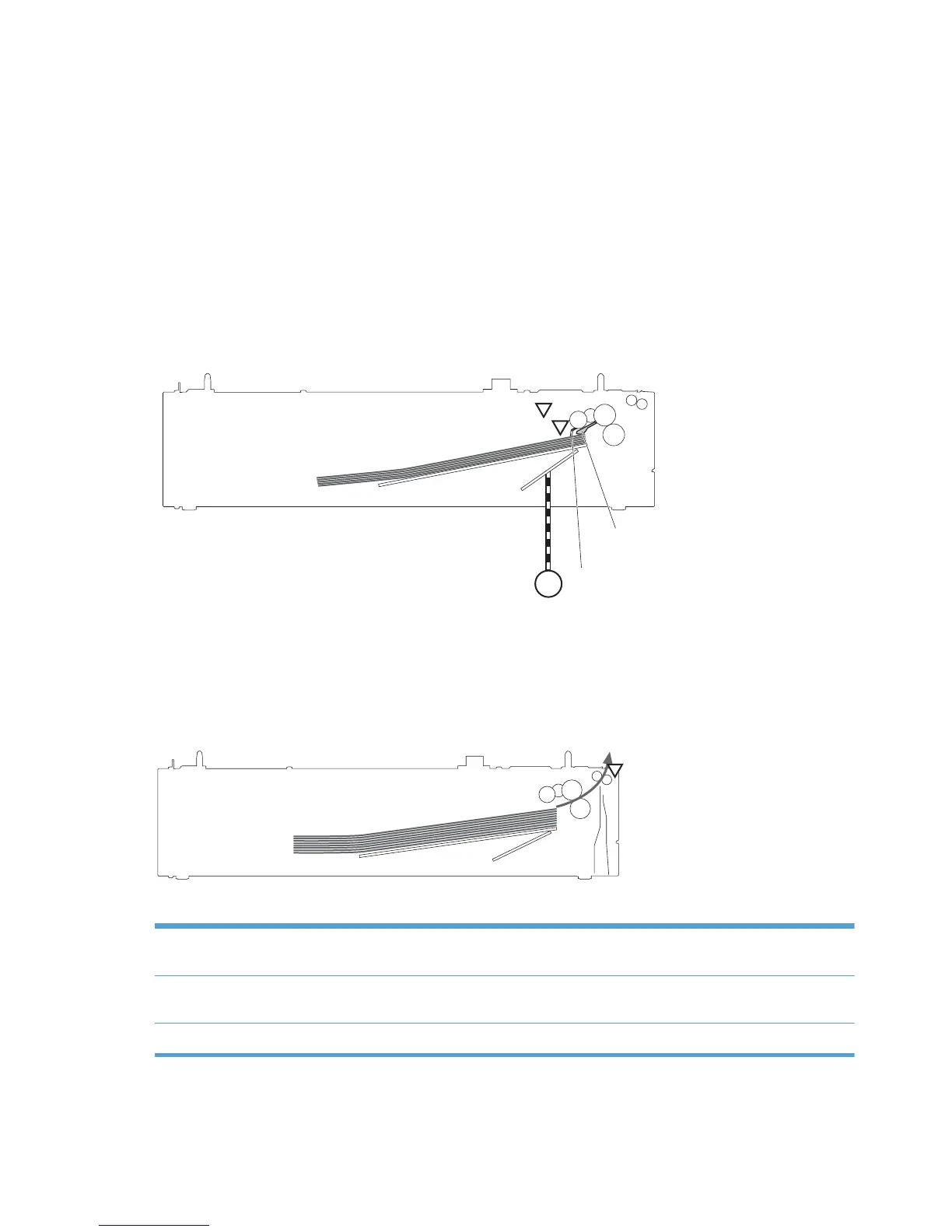

1x500-sheet paper feeder jam detection

The paper feeder uses the PF paper-feed sensor (SR1) to detect the presence of print-media and to

check whether print-media is being fed correctly or has jammed.

Figure 1-64 1x500-sheet paper feeder jam detection

SR1

Paper feeder 1

The paper feeder detects the following jams:

PF pickup delay jam The PF paper-feed sensor does not detect the leading edge of paper within a specified period,

including a retry, after the PF pickup solenoid is turned on.

PF residual paper jam The PF paper-feed sensor detects a presence of paper when the printer is turned on, when the

door is closed, or when the automatic delivery is performed.

PF door open jam A door open is detected during a paper-feed operation.

86 Chapter 1 Theory of operation ENWW

Loading...

Loading...