Booklet maker feed-and-delivery operation

Basic operation

Stacker unit basic operation

The stacker unit processes simple stacking, job offset, and stapling. The stacker controller PCA

controls all operations involved in these modes, according to the commands from the product. Jobs

from the product can also be routed for booklet making.

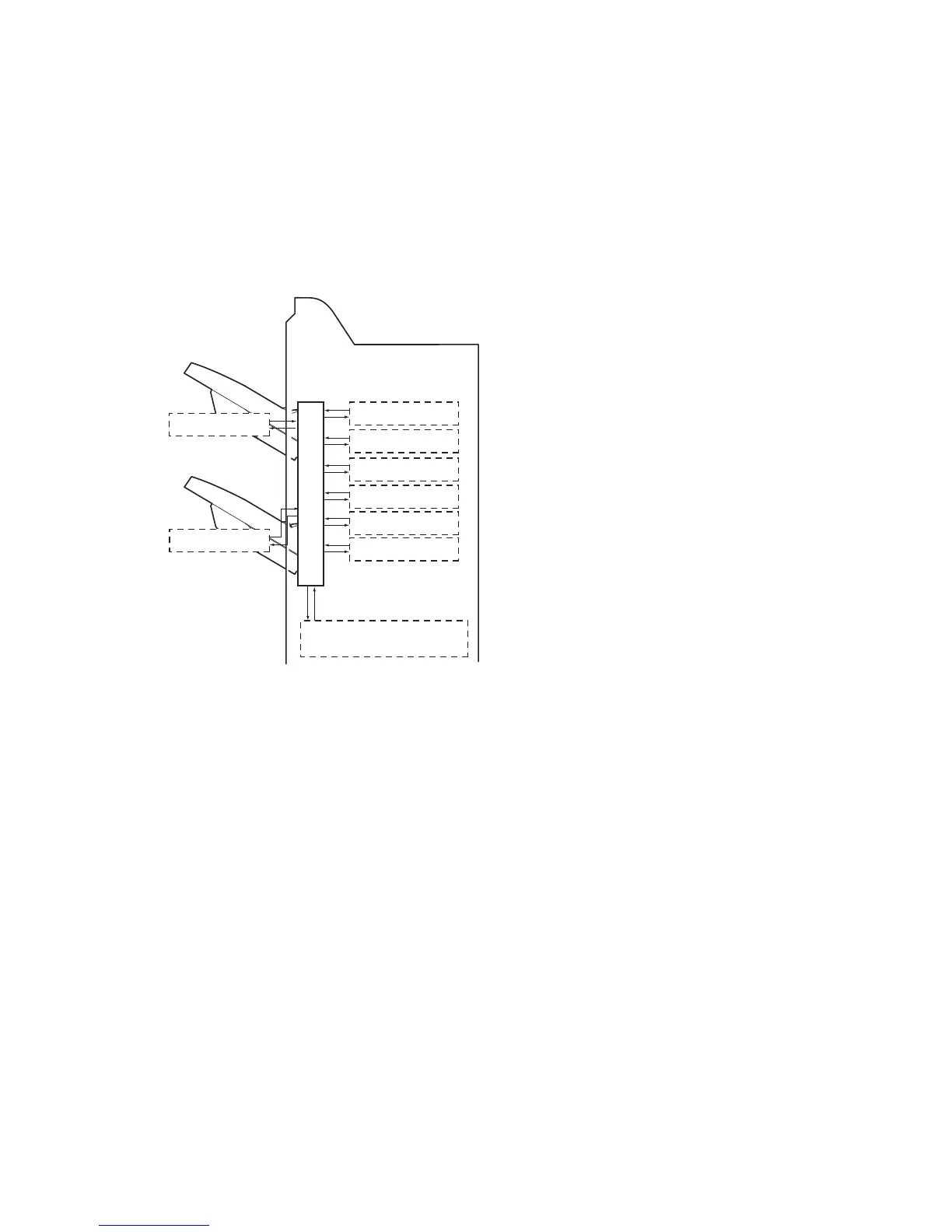

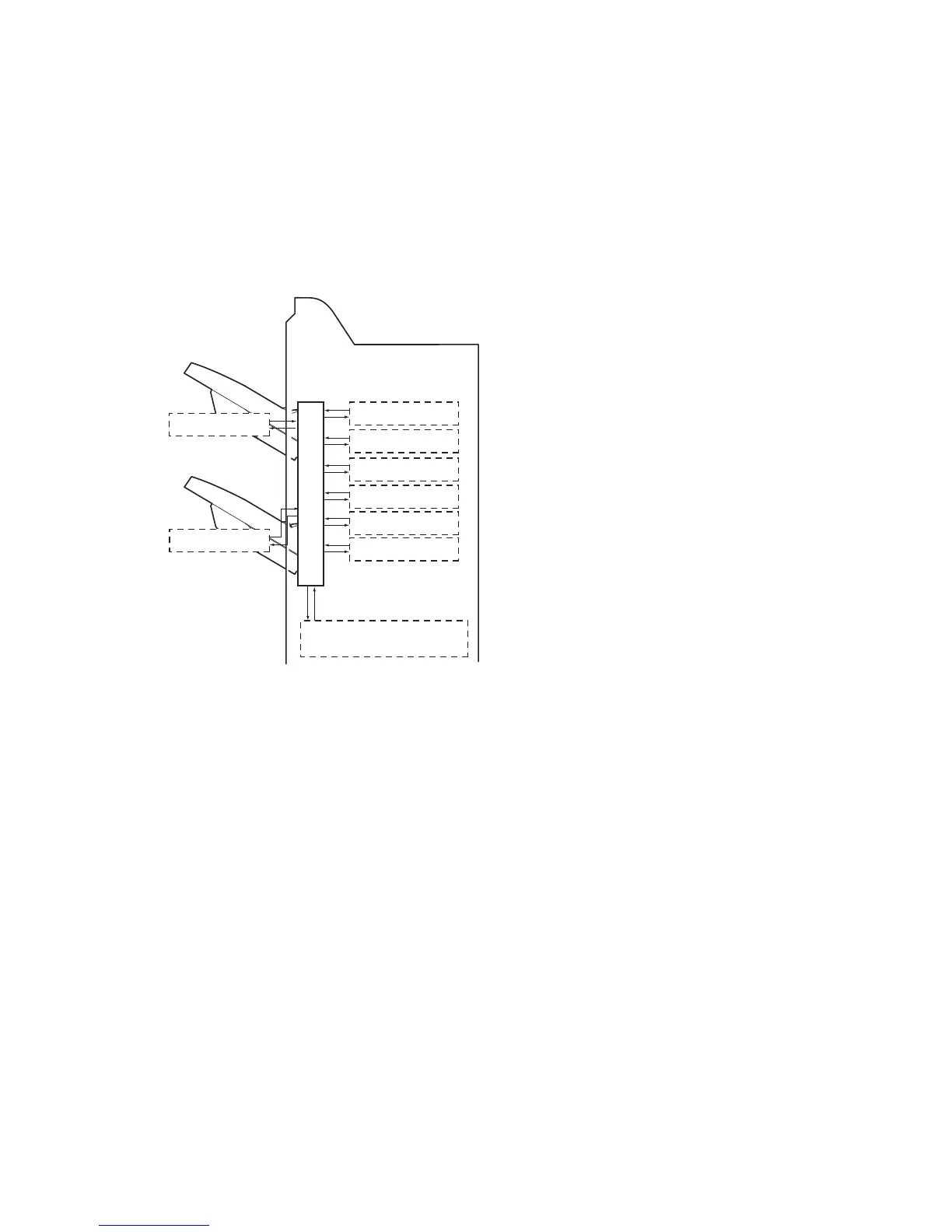

Figure 1-119 Stacker unit basics

Swing guide drive system

Alignment drive system

Stapler drive system

Delivery drive system

Feeder drive system

Shutter drive system

Output bin

drive system

Booklet making control system

(saddle stitcher controller PCB)

Control system

Output bin

drive system

Stacker unit electrical security

A 16-bit microprocessor (CPU) is installed on the stacker controller PCA to control the stacker

operation sequence and CAN signal communication with the video controller PCA. The stacker

controller PCA drives solenoids, motors, and so forth in response to the commands received from the

video controller through the CAN singnal communication line. In addition, the stacker controller PCA

reports information about various sensors and switches to the video controller through the CAN signal

communication line. Major functions of the IC chips installed on the stacker controller PCA are as

follows:

●

IC13 (CPU): Controls the operation sequence

●

IC10 (EEP-ROM): Backs up adjustment values

●

IC6 (Communication IC): Communicates with the host machine

●

IC12 (communication IC): Communicates with the saddle stitcher unit

ENWW Booklet maker and booklet maker with hole punch 165

Loading...

Loading...