420010970100 - LP-699 Rev. 000 Rel. 001 Date 6.11.20

5

Products to Avoid

Areas Likely to Have

Contaminants

Spray cans containing

uorocarbons

Dry cleaning / laundry areas

and establishments

Permanent wave solutions Swimming pools

Chlorinated waxes / cleaners Metal fabrication plants

Chlorine-based swimming pool

chemicals

Beauty shops

Calcium chloride used for

thawing

Refrigeration repair shops

Sodium chloride used for water

softening

Photo processing plants

Refrigerant leaks Auto body shops

Paint or varnish removers Plastic manufacturing plants

Hydrochloric or Muriatic acid

Furniture renishing areas and

establishments

Cements and glues New building construction

Antistatic fabric softeners used

in clothes dryers

Remodeling areas

Chlorine-type bleaches, laundry

detergents, and cleaning

solvents

Garages and workshops

Adhesives used to fasten

building products

Table 1 - Products and Areas Likely to Have Contaminants

NOTE: DAMAGE TO THE Boiler CAUSED BY EXPOSURE TO

CORROSIVE VAPORS IS NOT COVERED BY WARRANTY. (Refer to

the limited warranty for complete terms and conditions.)

E. General Cautionary Statements

The boiler is protected from malfunctioning by means of internal

checks performed by the electronic microprocessor PCB, which

stops the boiler from operating if necessary. In the event of the

boiler being shut o in this manner, a code appears on the display

which refers to the type of shut-o and the reason behind it.

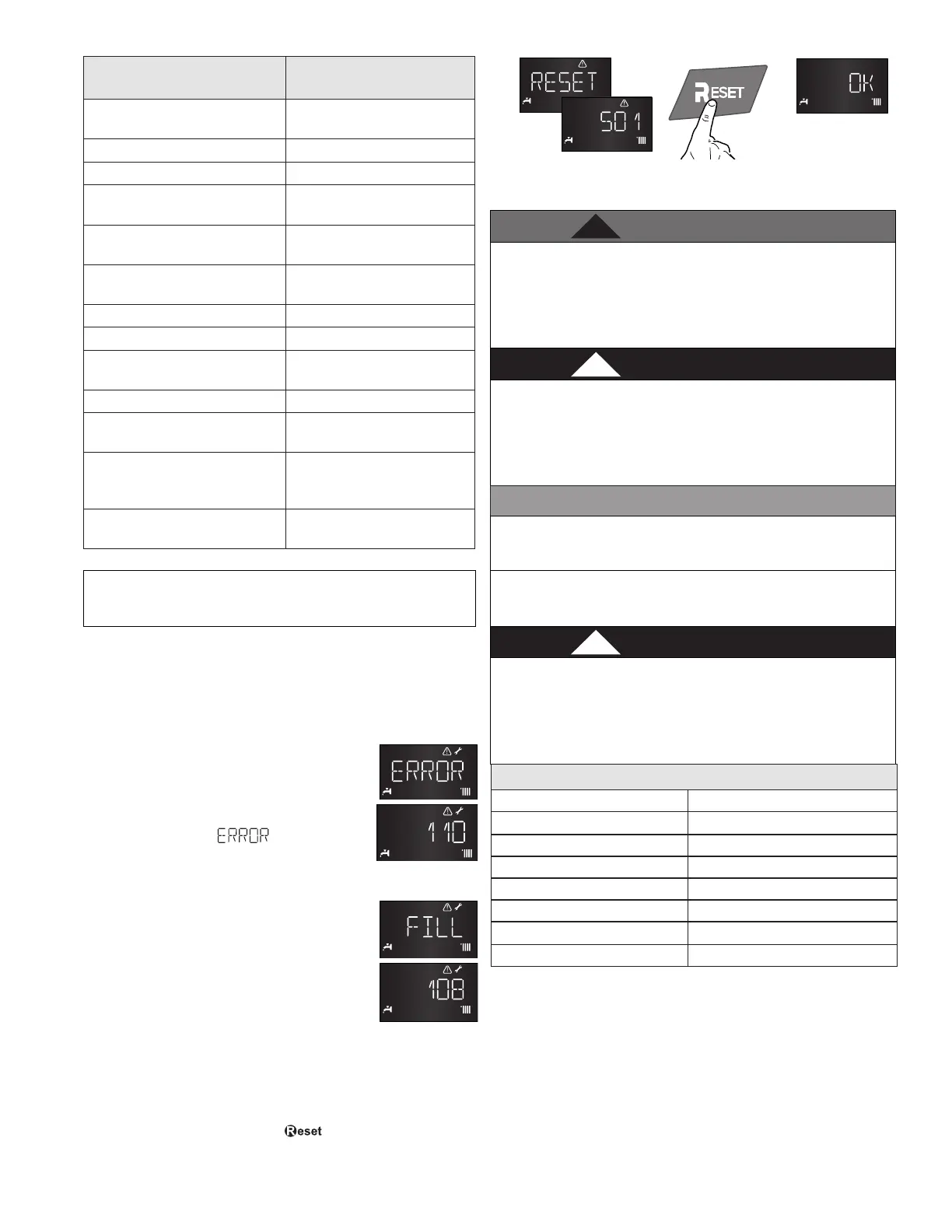

1. Blocking Error

A blocking error means the boiler will restart

automatically as soon as the problem which

caused the error clears or is removed; the error

is indicated by the « » symbol which

appears on the display followed by the error

code.

For example, if the boiler indicates a 110 error

code, the error will clear automatically when the

CH temperature decreases. The boiler will restart

and operate normally.

Figure 1 - Blocking

Error Example

NOTE: Contact a qualied service technician if the

error continues to occur.

In the event of Error 108 - Shut-o due to

insucient water pressure inside the heating

circuit - turn the boiler o. Turn the external

electric power to the OFF position. Shut o the

main gas valve and contact a qualied service

technician to check for any leaks of water.

Figure 2 - Shut-

O Error for Low

Water Pressure

2. Lockout Error

A lockout error means the boiler does not return to operation after

the error condition goes away. The button must be pressed on

the control panel to restore boiler operation.

Figure 3 - Lockout Error Example

If the error condition occurs often contact a qualied service technician.

Important

Contact a qualied service technician for assistance if a Lockout Error

occurs frequently. Repeated Lockout Error conditions could indicate

a serious error with the boiler or installation. Failure to contact a

qualied service technician to troubleshoot the error could result in

substantial property damage, serious personal injury, or death.

If the boiler signals the error again after a reset, turn o the boiler.

Move the external electric switch to the OFF position. Close the gas

valve and contact a qualied service technician.

DO NOT attempt to repair or service this boiler. Contact a qualied

service technician if the boiler needs repair or maintenance. Ask your

gas supplier for a list of qualied service providers.

Ensure each zone valve connected to the boiler is open while

the boiler is operating. Doing so ensures proper heating system

operation.

DO NOT wipe the boiler or control panel with a wet cloth. Doing

so may result in an electric shock, substantial property damage,

premature boiler failure, severe personal injury, or death.

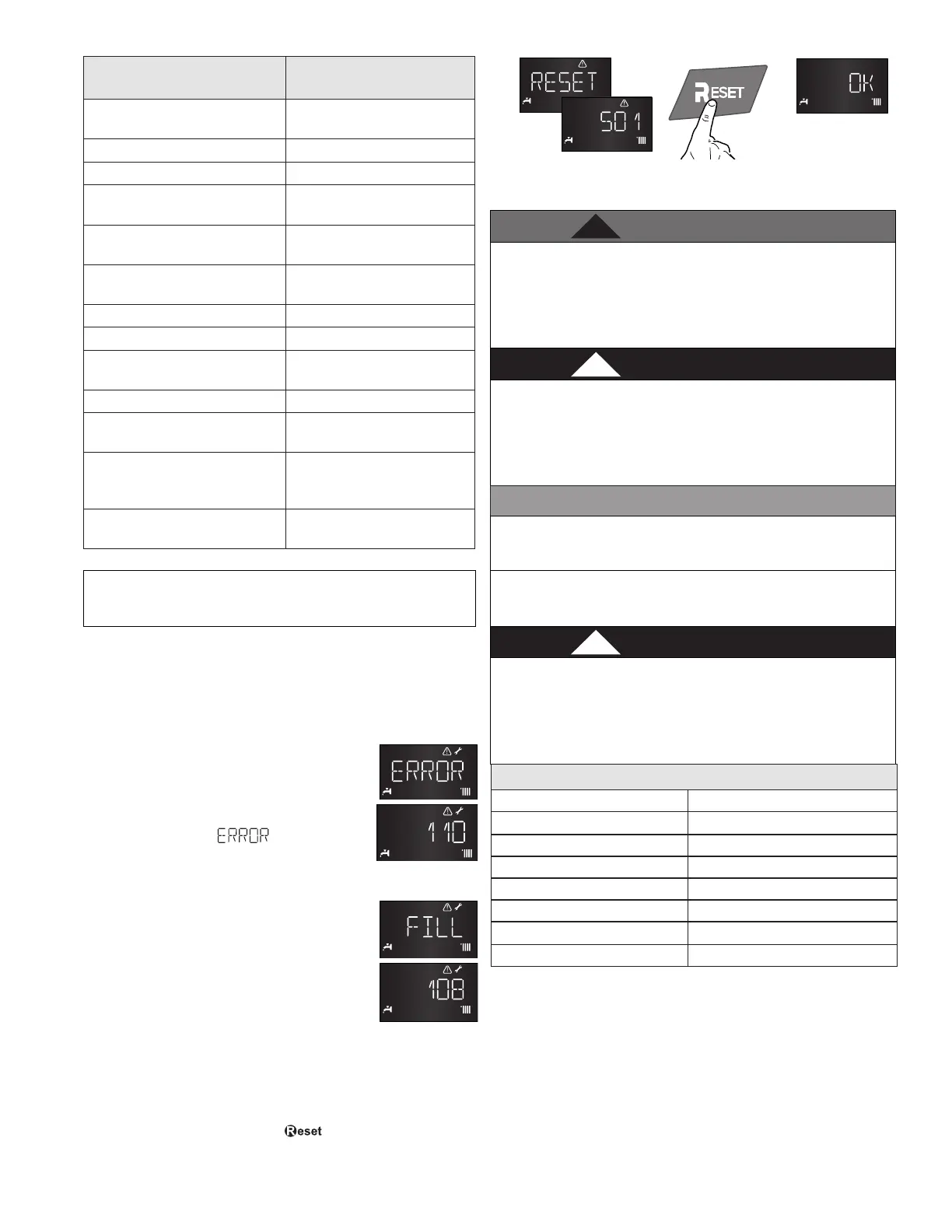

There are two types of shut-o:

Always be careful when opening a hot water faucet or draining water

from the boiler. Water temperature over 125

o

F can instantly cause

severe burns or death from scalds. Children, disabled, and elderly

are at the highest risk of being scalded. See Installation Manual

before setting temperature at boiler. Feel water before bathing or

showering!

Approximate Time / Temperature Relationships in Scalds

120

o

F More than 5 minutes

125

o

F 1 1/2 to 2 minutes

130

o

F About 30 seconds

135

o

F About 10 seconds

140

o

F Less than 5 seconds

145

o

F Less than 3 seconds

150

o

F About 1 1/2 seconds

155

o

F About 1 second

Table 2 - Time and Temperature Relationship in Scalds

Loading...

Loading...