LP-314 Rev. 012 Rel. 003 Date 9.27.19

6

Households with small children, disabled, or elderly persons may

require a 120

o

F or lower temperature setting to prevent severe

personal injury or death due to scalding.

G. Water Temperature Adjustment

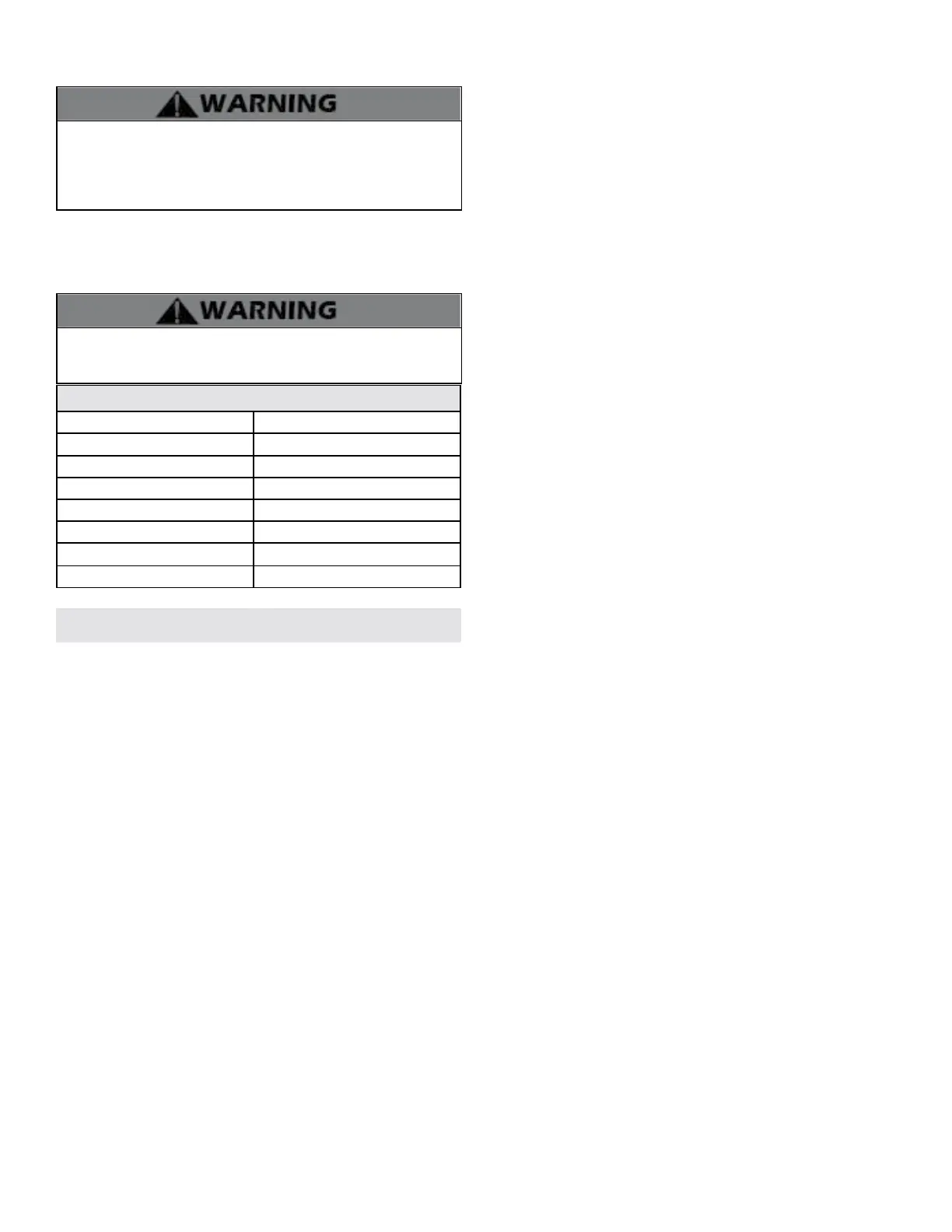

If the appliance is going to have a set temperature above 120

o

F, you

must use an ASSE 1017 rated mixing valve to avoid severe burns or

death from scalding temperatures.

F. High Elevation Installations

Natural gas at high elevation might contain less heating value than

typical 1,000 BTU/cu ft and therefore can cause improper air / gas

mix leading to improper combustion. For natural gas installations

above 3,000 ft, call your gas provider to determine the heating value

of the supplied natural gas.

Approximate Time / Temperature Relationships in Scalds

120

o

F More than 5 minutes

125

o

F 1 1/2 to 2 minutes

130

o

F About 30 seconds

135

o

F About 10 seconds

140

o

F Less than 5 seconds

145

o

F Less than 3 seconds

150

o

F About 1 1/2 seconds

155

o

F About 1 second

Table 1 - Approximate Time / Temperature Relationships in Scalds

B. How the Appliance Operates

The Versa Hydro with Total System Control provides high eciency

central heating and domestic hot water from one appliance. Total

System Control manages system needs, ensuring maximum comfort

and ecient operation. Some features of the appliance are:

Stainless Steel Water Storage Tank

The storage tank is constructed of 316L stainless steel to provide

maximum corrosion resistance. Water blown foam insulation and a

plastic jacket provide superior insulation, allowing no more than ½

degree heat loss per hour.

High Eciency Heat Exchanger

The 90/10 copper nickel heat exchanger provides highly ecient

energy transfer. Hot gases from the primary circuit heat the combustion

walls. The walls transfer heat directly into the domestic water. The

secondary circuit then transfers the last bit of energy to the bottom

of the tank, where hot gases are converted to water vapor, giving the

appliance a combustion eciency of 98% and thermal eciency of up

to 96%.

Components included with the appliance:

• Intake PVC Tee with Screens

• Exhaust PVC Coupling with Screens

• Temperature and Pressure Relief Valve

• Installation Manual and Warranty

• User’s Information Manual

• Solar Addendum (S Models Only)

• Outdoor Sensor (Part # 7250P-319)

• Mixing Valve (7100P-315)

A. What’s in the Box

Part 2 - Before You Start

Remove all sides of the shipping crate of the appliance.

Modulating Combustion System

The modulating combustion system regulates ring rate based on

heat demand. Total System Control monitors tank operation, system

parameters, and controls the ring rate of the burner, providing only

the energy required to satisfy both domestic hot water and central

heating needs.

Total System Control

Total System Control automatically manages the central heating

and domestic hot water systems through the use of sensors.

These sensors monitor inputs (such as outdoor temperature, tank

temperature, and heating module outlet temperature) providing

data that allows accurate control of the entire system. You may

choose to use the control’s factory default settings or reprogram

system parameters to provide design exibility.

Hydronic Heating Module

The hydronic heating module connects to the storage tank through

two dip tubes. The rst dip tube draws heated water from the top

of the storage tank and circulates it through a brazed plate heat

exchanger to transfer the water’s stored energy to the hydronic

side of the plate. Once the energy is transferred, the water returns

through the second dip tube to a lower section of the storage tank

to continue circulating. A stainless steel circulator pump modulates

output, varying ow through the brazed plate heat exchanger

to meet domestic hot water and central heating demand. An

outlet sensor provides feedback to the control to assure accurate

temperature control.

Venting System

This appliance must be exhausted to the outdoors. Use only the

approved venting materials outlined in the Venting section of this

manual. Vent size can vary from 2” to 3” depending on the appliance

input rate. Special attention should be taken when selecting vent

location. Vents can run horizontally or vertically, depending on

system design, and should be supported as shown in the Venting

section of this manual.

Burner

The burner is constructed of high grade stainless steel and uses pre-

mixed air and gas to provide a wide range of ring rates.

Condensate Drain Connection

This is a condensing high eciency appliance with a condensate

removal system. Condensate is nothing more than water vapor

derived from combustion products, similar to that of an automobile

when it is initially started. It is very important that the condensate

line slopes away from the appliance and down to a suitable inside

drain.

If the appliance condensate outlet is lower than the drain, use a

condensate removal pump (Part # 554200, available from HTP). In

addition, local authorities may require a condensate neutralizer to

neutralize the condensate. Condensate neutralizers are made up

of lime crystals, marble, or phosphate chips. Neutralizers can be

installed in the eld by the installer and purchased from HTP (7450P-

212).

It is also very important not to expose the condensate line to freezing

temperatures or any type of blockage. Plastic tubing must be the only

material used for the condensate line. Steel, brass, copper, or other

materials will be subject to corrosion or deterioration. A second vent

may be necessary to prevent condensate line vacuum lock on a long

horizontal run. Also, an increase in pipe size may be necessary to

allow condensate to drain properly. Support of the condensate line

may be necessary to avoid blockage of the condensate ow.

Spark Ignition

The burner ame is ignited by applying high voltage to the system

spark electrode. This causes a spark from electrode to ground.

Outdoor Sensor

Monitors outdoor temperature and adjusts the set point to provide

greater eciency.

Loading...

Loading...