30 TRANSMISSION—OVERDRIVE

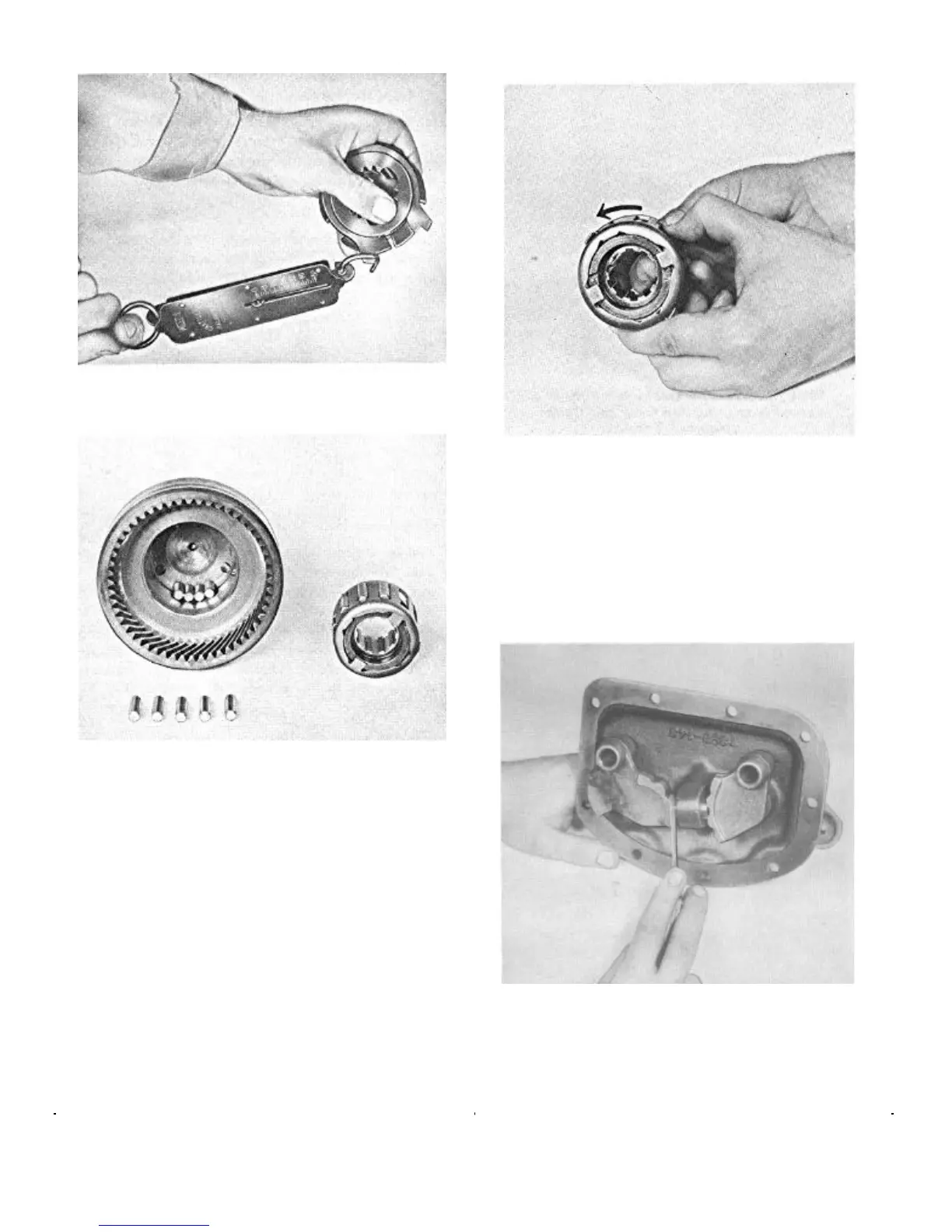

FIGURE 18—Inspection of Overdrive Parts is

Important. The Free Wheeling Rollers Will

Slip if these Parts Are Worn

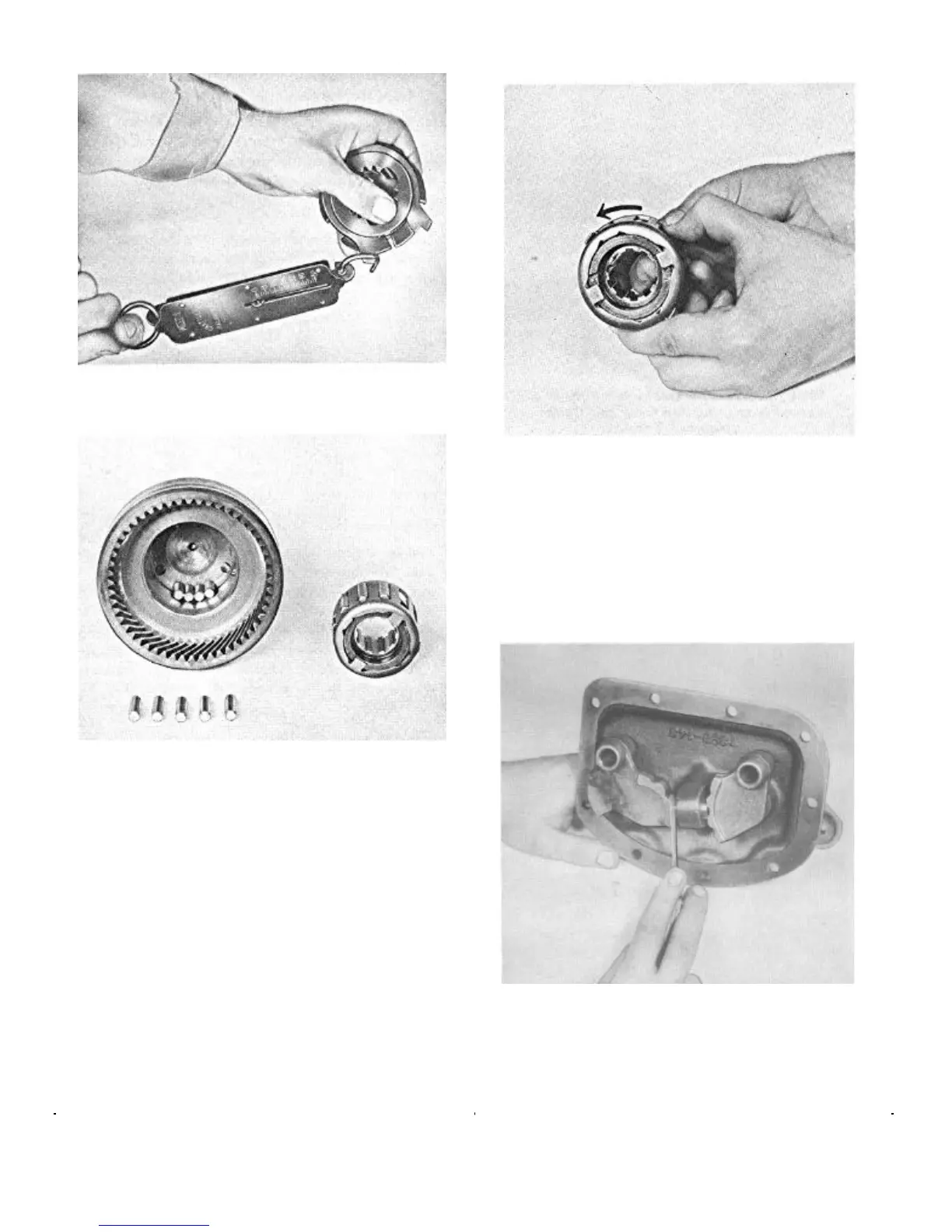

Test the action of the two cam retaining springs. These

springs are designed to twist the cam in a clockwise direc-

tion, thus holding the rollers up on the cam. If this spring

action is slow or retarded, it will result in a loud thump

whenever the free wheeling unit engages on acceleration.

To test it, grasp the cam roller retainer and turn it counter-

clockwise. Then release it suddenly. If the retainer springs

quickly back in a clockwise direction, the springs are all

right. If the action is sluggish, replace the springs (Fig. 19).

Transmission Cover and Shift Fork Assembly

To remove the transmission cover and shift fork assembly,

simply remove the nine attaching cap screws and slide the

assembly including the shift forks away from the transmis-

sion case. Remove the gasket and discard.

FIGURE 19—When You Twist the Cam Roller

Retainer Counter-clockwise, the Two Springs

Should Snap it Back Quickly

Interlock Sleeve End Clearance

Place one shift shaft in gear and with the other in the neu-

tral position measure the clearance between the interlock

sleeve and cam of the shift shaft at the in-gear side (Fig.

20).

FIGURE 20—Measuring Interlock Sleeve

End Clearance

This clearance should be maintained at .002" to .008".

Four different length sleeves are serviced in .005" varia-

tions.

Disassembly of the cover and shift fork assembly

FIGURE 17—Measuring Balk Ring Tension

with Spring Scale-3-1/2# to 5-1/2# Pull

Loading...

Loading...