18

Check the following before asking for repair. For follow-up service and any inquiry you may have while using

the product, please contact our Customer Center, or homepage at http://www.globalhurom.com Check the

manufacturer’s number or the number under the barcode when requesting for follow-up service or parts.

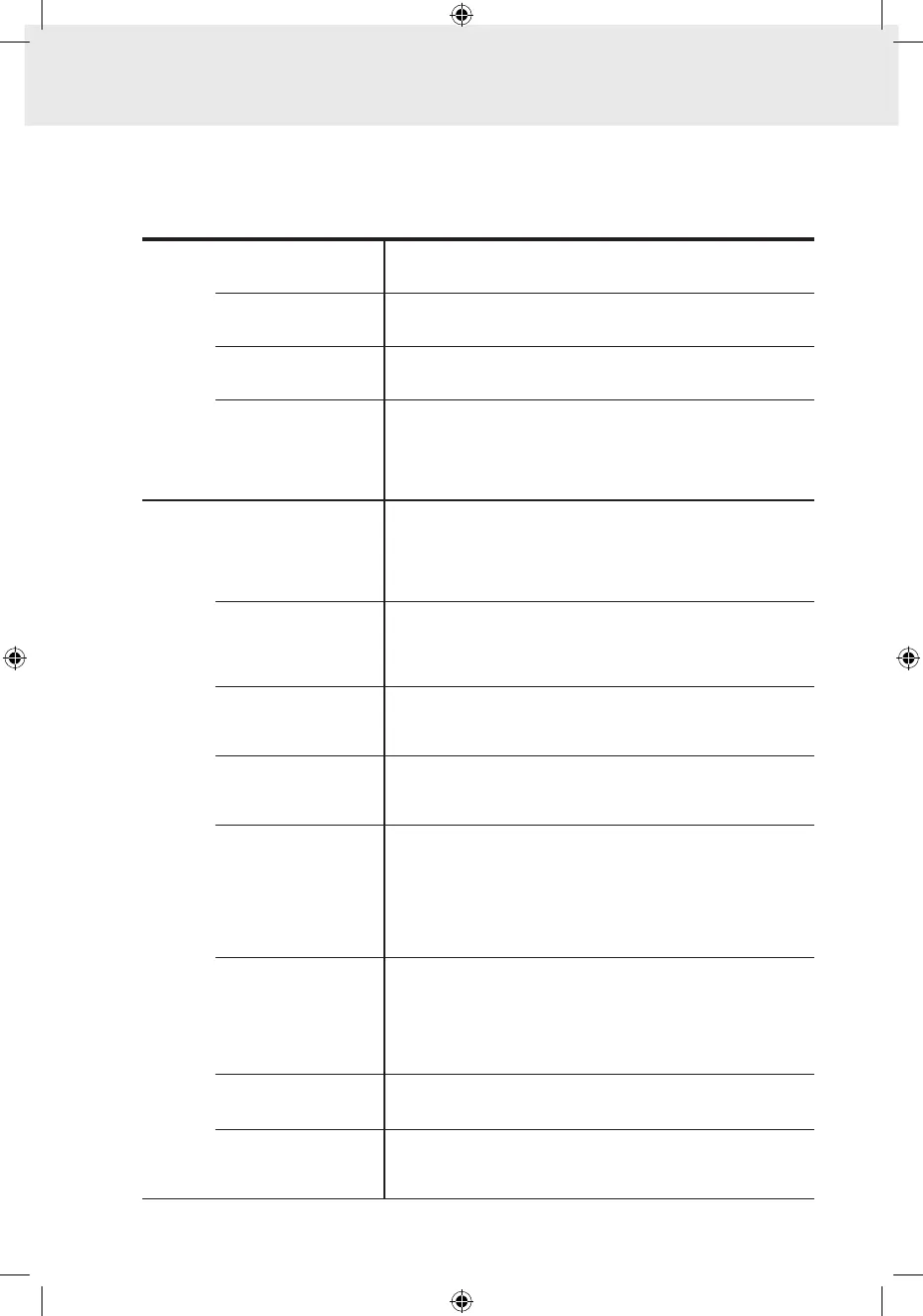

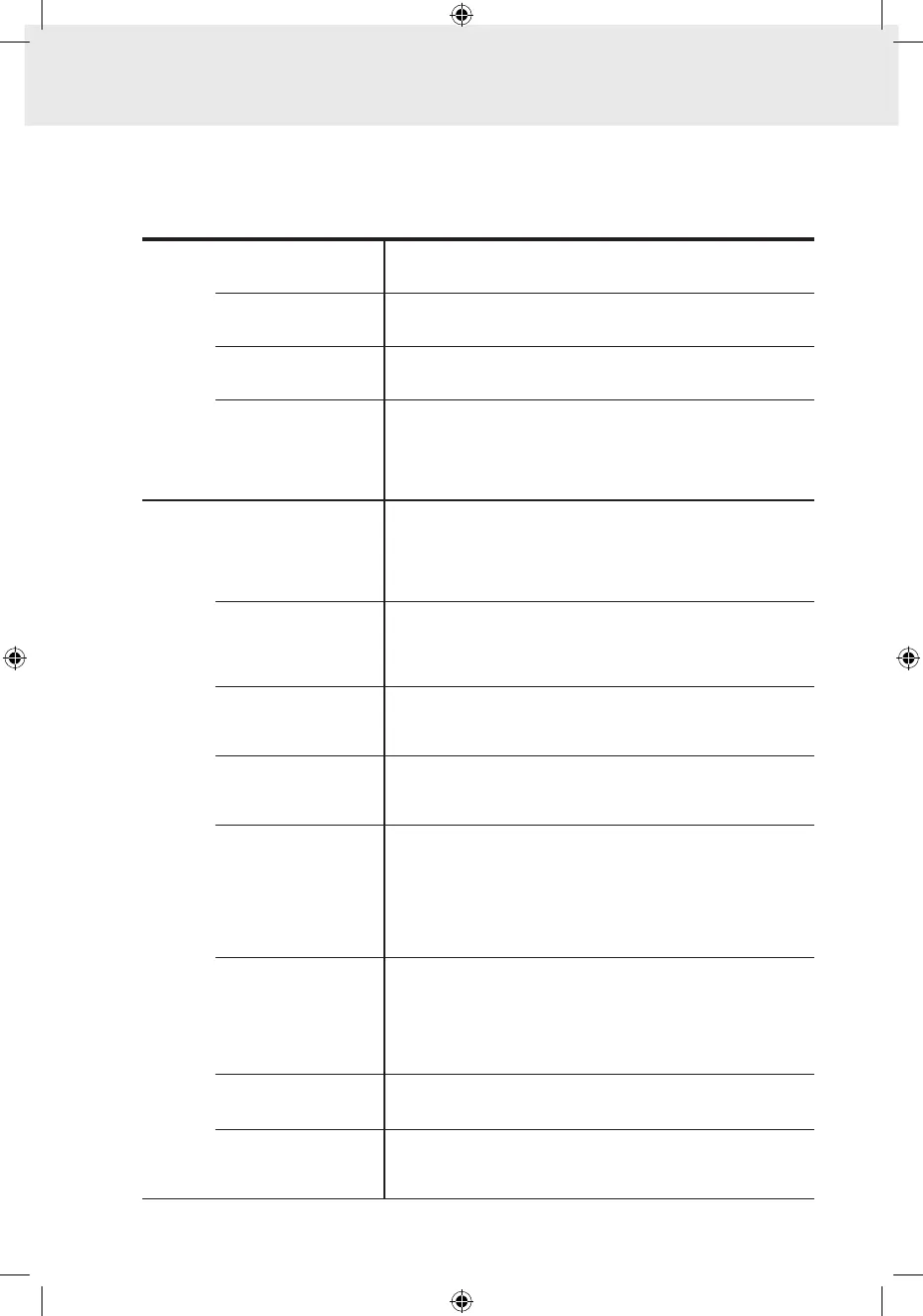

12. Before Requesting for Repair

Common

It does not operate only

with the product body.

Check if the chamber set of the juicer or the container of the blender and

the product body are properly assembled. Make sure to turn the power off

when assembling or disassembling the product.

Assemble it so that it is

aligned with the safety

sensor.

Check if it is assembled in accordance with the guide mark. Make sure to

turn the power off when assembling or disassembling the product.

There are cracks or

scratch marks on the

product.

In the process of making the molding, curve-shaped marks are created in

addition to the straight-lined mold marks. They are normal parts and do not

affect the operation at all.

It does not work.

Check if the power cord is properly inserted. The machine may not

work after a long period of use. It will operate normally after the heat of

the product body (motor) cools down. Check if the product is properly

assembled. If the product is assembled incorrectly, it will not work. Check

if the product is assembled according to the steps specified in the assembly

guide. Refer to the assembly guide page.

The juicer stops operating

during juicing.

Juice may leak through the pulp outlet immediately after inserting

ingredients. Have an excessive amount of ingredients or extremely thick

ingredients been inserted? Refer to Page 11 of the manual to activate a

reverse rotation. For safety, a timer, which automatically stops after about 5

minutes from the start of operation, is set. Press the [START/STOP] button

again briefly to start operation.

Juice leaks through the

pulp outlet immediately

after

the ingredients are

inserted.

Depending on the inserted ingredients, small amounts of juice may

leak through the pulp outlet. This is not a product defect but, rather, a

phenomenon caused by the characteristics of the ingredients. The leakage

will stop once the product starts running. If the leakage continues, contact

the Customer Service Center.

Juicer

Juice flows back into the

hopper.

Did you extract juice with the juice cap closed? When juicing with the juice

cap closed, the juice may flow backward into the hopper. If the contents are

not sufficiently discharged even after opening the juice cap again, open the

hopper cover and empty out the contents.

Juice leaks between the

hopper and the chamber,

or between the chamber

and the product body.

Is the hopper packing or chamber packing assembled correctly? The juice

will leak if the hopper packing or chamber packing has been assembled

upside-down or incompletely. Check if the packing is assembled properly.

The hopper does not open.

There may be excessive pulp remaining inside. Operate the product to

discharge the pulp inside or repeat the process of activating a reverse

rotation for about 10 seconds and then stopping 2 to 3 times. Then, the

hopper will open without any issue. Were any foreign substances or solid

matter (hard seeds such as persimmon seed) inserted? If any foreign

substances or solid matters are inserted, parts may be damaged more

seriously when attempting a reverse rotation so contact the Customer

Service Center and request after-sales service.

The chamber shakes

during juicing.

The product may wobble slightly due to the motions of the product body's

motor. Depending on the ingredients' characteristics (hard or tough),

motions are generated in various magnitudes. This is not a malfunction

but, rather, a normal phenomenon observed when the screw rotates.

Compared to soft ingredients with much water content, relatively harder

ingredients may seem to produce a greater vibration. (e.g., carrots,

potatoes, radishes, beets, kohlrabi, etc.)

The discharge cover is

closed but the pulp is

discharged.

Even if the lever is closed, pulp will be discharged naturally. Depending on

the ingredients used, there may be a difference in the amount and speed of

discharge.

An unusual noise is heard

while juicing.

It is a natural sound produced when ingredients are being crushed. If the

ingredients are hard or tough like apples, carrots, cabbage, celery, beets,

etc., the extraction noise may be louder than that heard when juicing softer

ingredients.

Loading...

Loading...