Do you have a question about the Husqvarna Viking H Class 200S and is the answer not in the manual?

Safety warnings to prevent electric shock.

Safety warnings to prevent burns, fire, shock, or injury.

Precautions regarding moving parts during operation and maintenance.

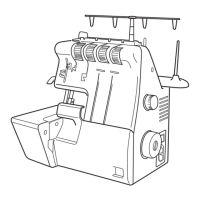

Comprehensive guide to threading the machine's lower looper, upper looper, and needles.

Guide to convert the machine for two-thread overlock stitching.

Adjusting thread tensions for two-thread overlock stitches.

Adjusting thread tensions for four-thread overlock stitches.

How to adjust the cutting width for overedge seams.

How positive differential feed prevents fabric stretching.

How negative differential feed prevents fabric puckering.

Adjusting presser foot pressure for different fabric types.

Instructions for replacing a blunt moving cutter.

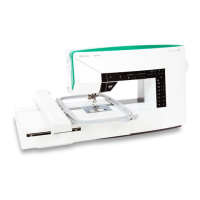

| Max Stitch Width | 5 mm |

|---|---|

| Max Stitch Length | 4 mm |

| Weight | 6.5 kg |

| Bobbin Type | Drop-in |

| Buttonhole Styles | 1 |

| Needle Threader | Automatic |

| Display | LCD |

| Buttonhole Type | 1-Step |

| Power Supply | 110-120V |

| Stitches | Decorative |

| Stitch Width | 5 mm |

| Stitch Length | 4 mm |

| Type | Electronic Sewing Machine |