USER MANUAL - OPAL-22 AUDIO INTERFACE

PAGE 6PAGE 5

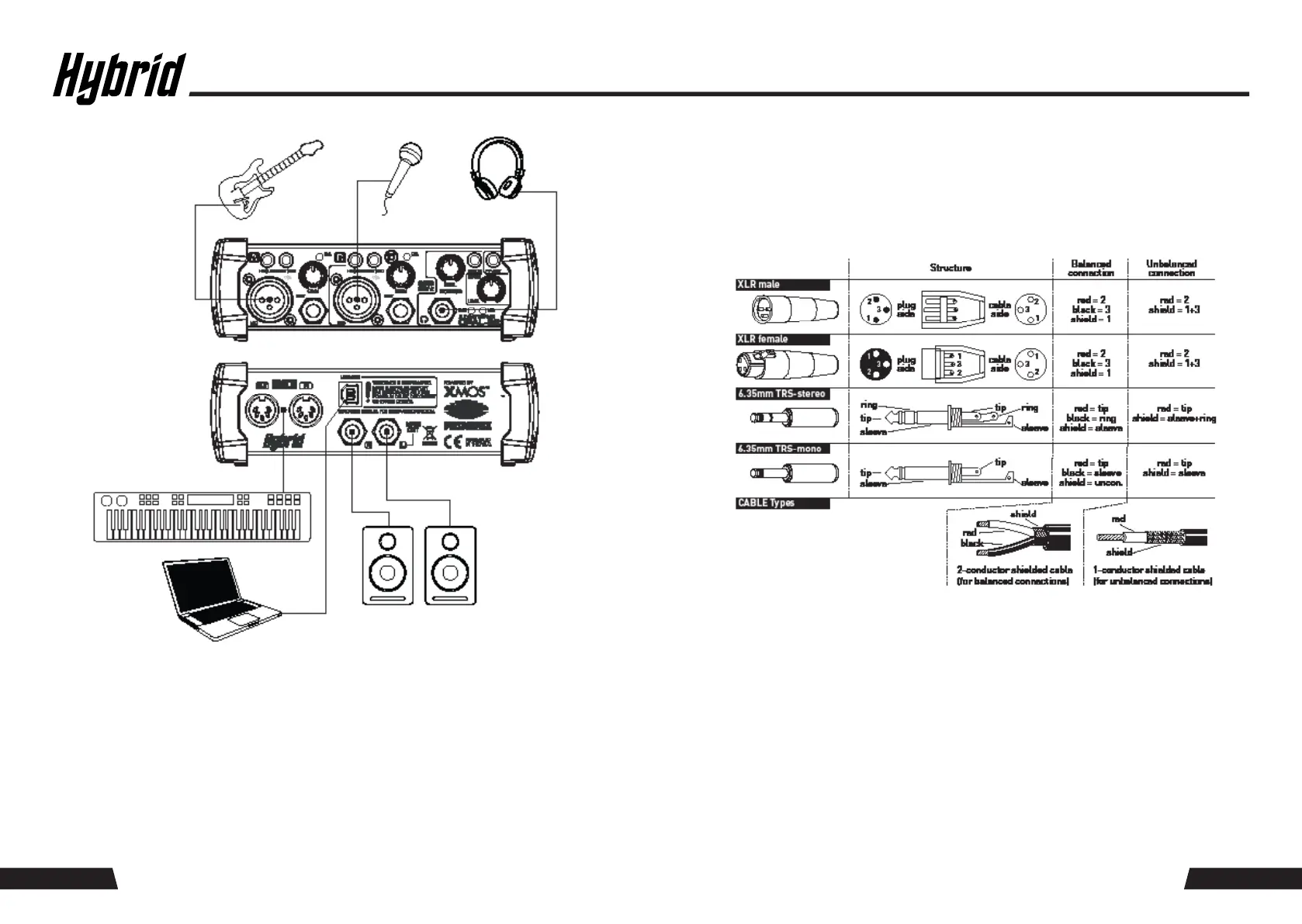

This setup illustrates the most typical configuration for recording with DAW software on your PC,

recording a guitar through Input A and vocals through Input B into a DAW software on the PC, while

monitoring the playback from the DAW via headphones or loudspeakers.

Mic input impedance ......................................... 2.70 kOhm

Mic input gain ...................... -0.5 to -44 dBu FS @ 600 Ohm

Mic input frequency response ... +0/-0.2 dB (20Hz to 20kHz)

Mic dynamic range (@ max gain) ........ 75 dB (A-weighted)

Mic input THD&N (1kHz@max gain) ............ -73dB=0.022%

Instr. Hi/LoZ input impedance ............. 220 kOhm/10 kOhm

Instr. input LoZ gain ........................... +12.6 /-30.8 dBu FS

Instr. input HiZ gain .............................. -1.8 /-45.3 dBu FS

Instr. input frequency response ... +0/-0.3 dB (20Hz-20kHz)

Instr. input dyn. range (@ max gain) .... 73 dB (A-weighted)

Instr. input THD&N (1kHz@max gain) .... -70 db = 0.032%

Line Output max. level/impedance ....... 12.9 dBu / 110 Ohm

Headphone Output power/impedance ........ 20 mW in 16/32 Ω

Sampling rates ......................... 44.1 kHz / 48 kHz / 96 kHz

Dynamic range ADC (24 Bit) ...................................... 102dB

Dynamic range DAC (24 Bit) ................................... 104dB

Dimensions............................ W157.5 x H49.0 x D131.5mm

Weight .................................................................... 0.45kg

USAGE EXAMPLE CONNECTIONS

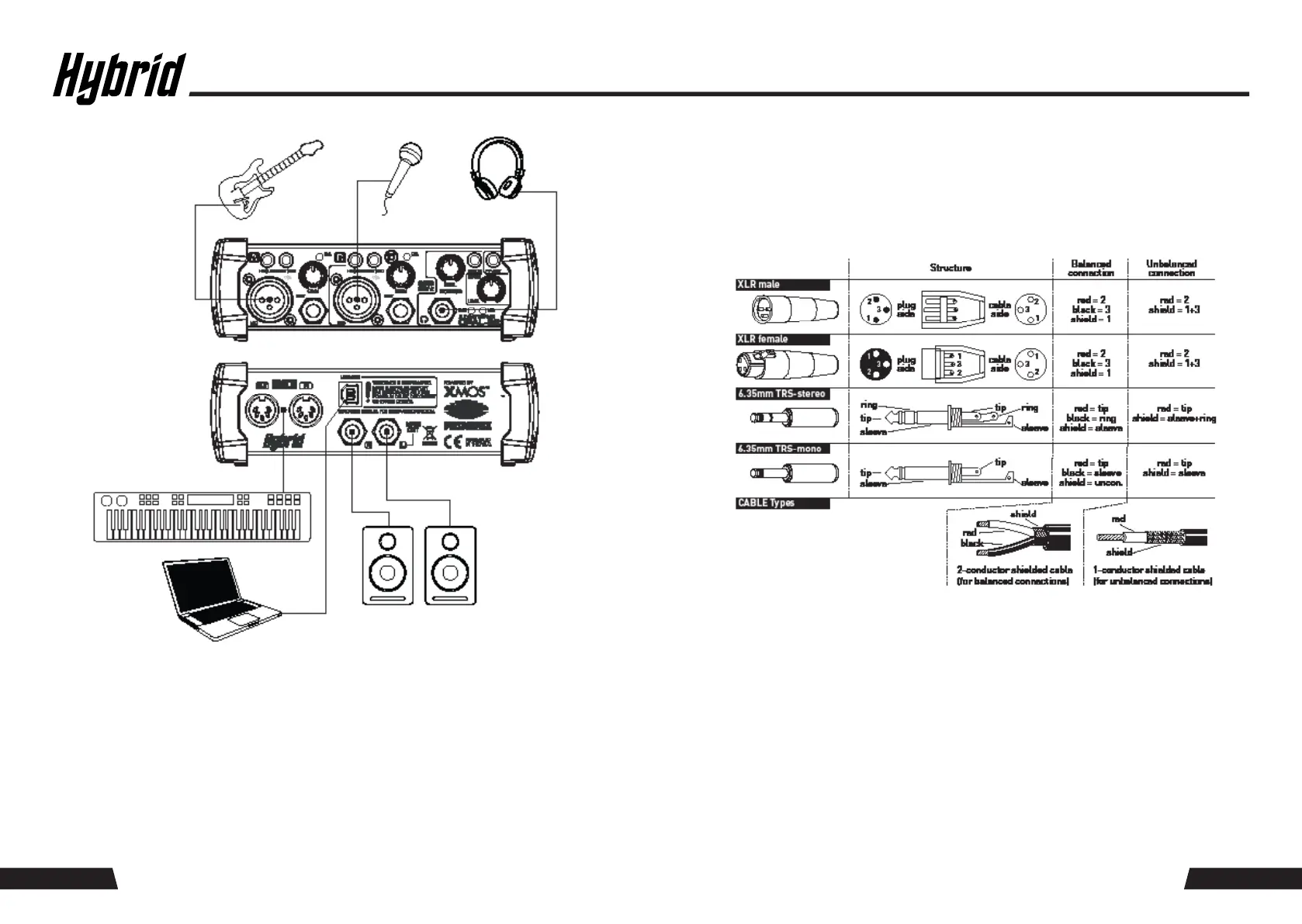

The OPAL-22 use the below connector types, for which the pin assignment must comply with

the following specification. Always make sure to use good connectors and cables to ensure

proper operation. Balanced connections are to be preferred over unbalanced connections

where applicable and feasible. Avoid unbalanced connections exceeding 2m of cable length.

MAINTENANCE AND WARRANTY

While we have chosen the best components to make this product as rugged and reliable

as possible, some parts in audio products (potentiometers, faders, switches) are subject to

wear which is a matter of operation cycles, and not of time.

In many cases, malfunction of electro-mechanical parts occurs due to dust contamination,

which may require cleaning of such parts. As the inside of such parts is not accessible,

a common practice is to use cleaning fluids in the shape of sprays. Please be reminded

that many of such fluids contain chemicals which may wash away the dust but at the same

time corrode or damage contact surface and may cause cosmetic damage to other parts.

We hence explicitly exclude any claims for exchange of damaged part due to mechanical

or chemical impact.

1 YEAR GUARANTEE

Loading...

Loading...