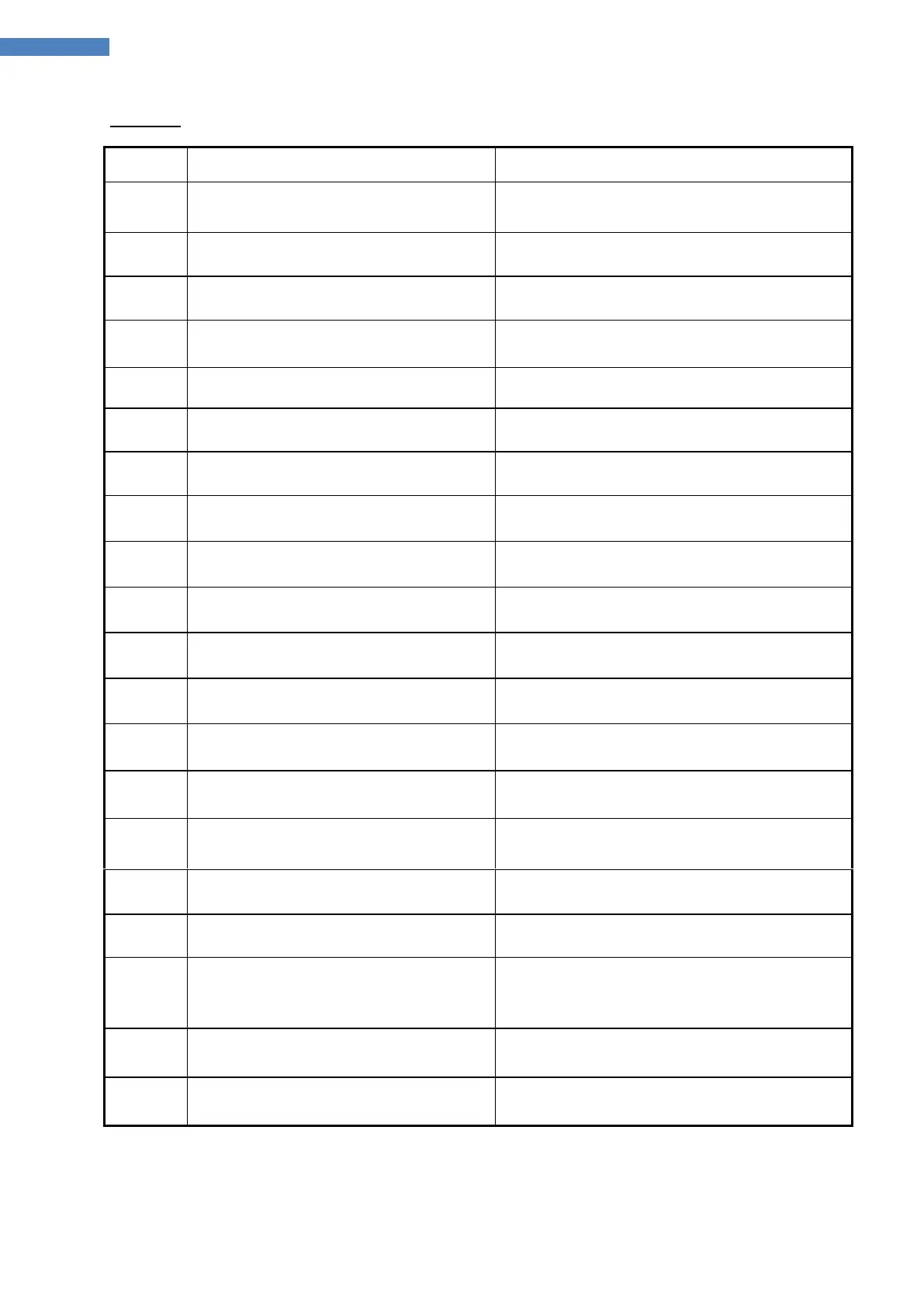

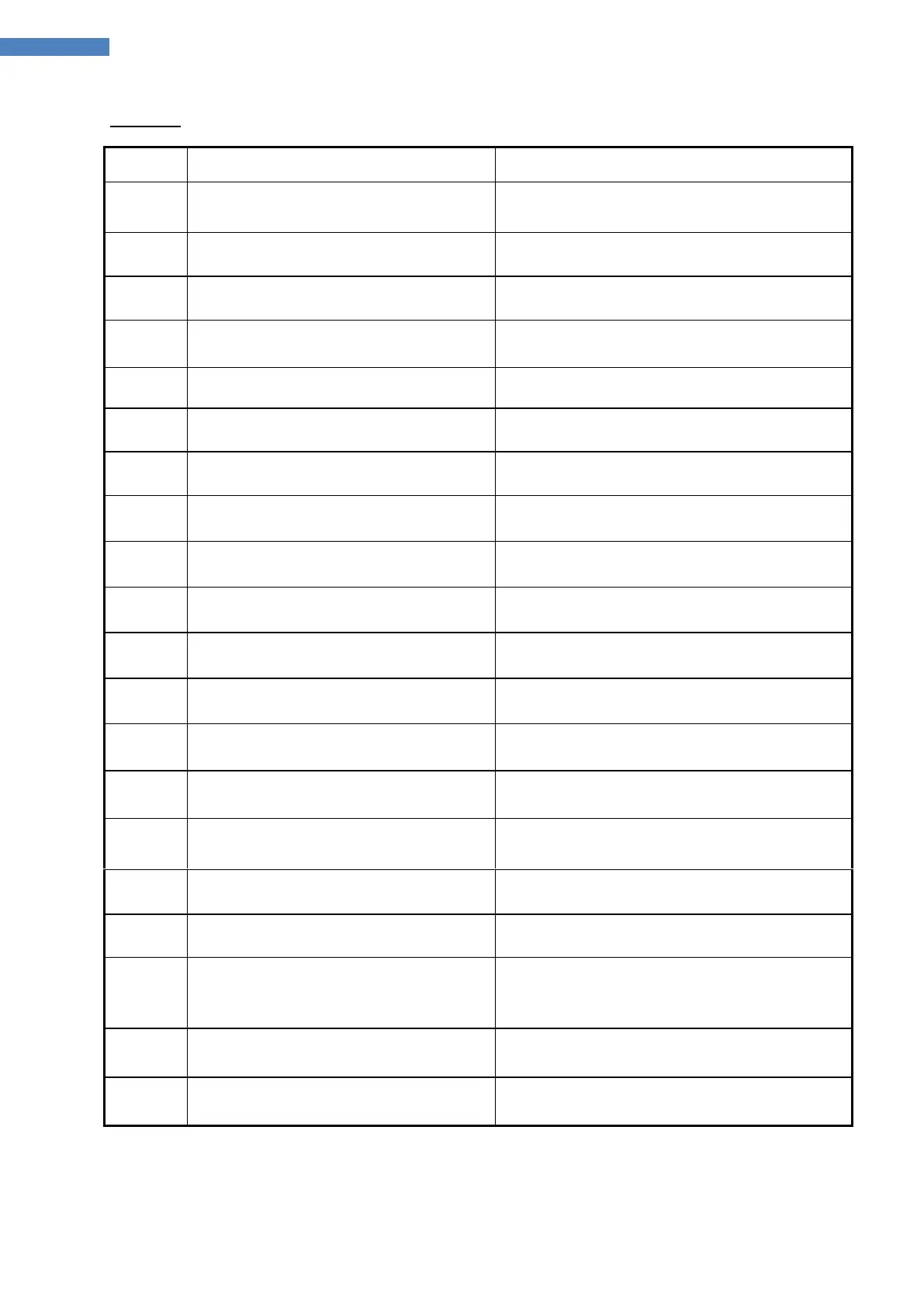

User Manual | Temperature Controller Display HIB123 Part-No.: 3756766 Doc.-Version: I

Warnings

refill the coolant up to the MAX-mark (tank)

causes: leakage, evaporation, defective level switch

clean or change air filter

causes: defective (differential) pressure switch

insert air filter

causes: defective monitoring switch

check coolant circuit

causes: defective pump/valves/hoses, defective flow sensor, soiled filter (if present)

Misc. warning 1 (definition: see circuit diagram input

E03)

depending on the function

Misc. warning 2 (definition: see circuit diagram input

E04)

depending on the function

KK 1 | Low temperature warning

temperature is less than parameter A3

(see parameter group USR)

KK 1 | High temperature warning

temperature is greater than parameter A4

(see parameter group USR)

KK 2 | Low temperature warning

temperature is less than parameter A43

(see parameter group USR)

KK 2 | High temperature warning

temperature is greater than parameter A44

(see parameter group USR)

KK 3 | Low temperature warning

temperature is less than parameter A53

(see parameter group USR)

KK 3 | High temperature warning

temperature is greater than parameter A54

(see parameter group USR)

change DI cartridge

causes: no use of DI water, defective valve for conductance control

Automatic venting process

(Time delayed, automatic restart of the plant)

* signaling via alarm interlock

Valve setting not in air vent position

No action required: automatic restart after max. 300 seconds

Low temperature warning

* signalling via alarm interlock / MFO-Interlock

temperature is less than parameter A28

High temperature warning

* signalling via alarm interlock / MFO-Interlock

temperature is greater than parameter A29

Refrigeration Circuit | low pressure warning

*signalling via alarm interlock / MFO-Interlock

contact service hotline

causes: loss of refrigerant, defective refrigerant component

Refrigeration Circuit | high pressure warning

* signalling via alarm interlock / MFO-Interlock

Air cooled: Clean air filter and check air supply

Water cooled: Clean strainer

Contact service hotline if necessary

causes: defective fan, no flow in external water circuit, open housing

Refrigeration Circuit | Motor circuit breaker has

triggered

* signalling via alarm interlock / MFO-Interlock

open switch cabinet and reset motor circuit breaker

cause: defective live component

Defective conductance sensor

measured value out of range

check electrical connection

change conductance sensor

*Notes on U33, U34, U35, U40, U41, U42 on the previous page.

Loading...

Loading...