User Manual | Temperature Controller Display HIB123 Part-No.: 3756766 Doc.-Version: I

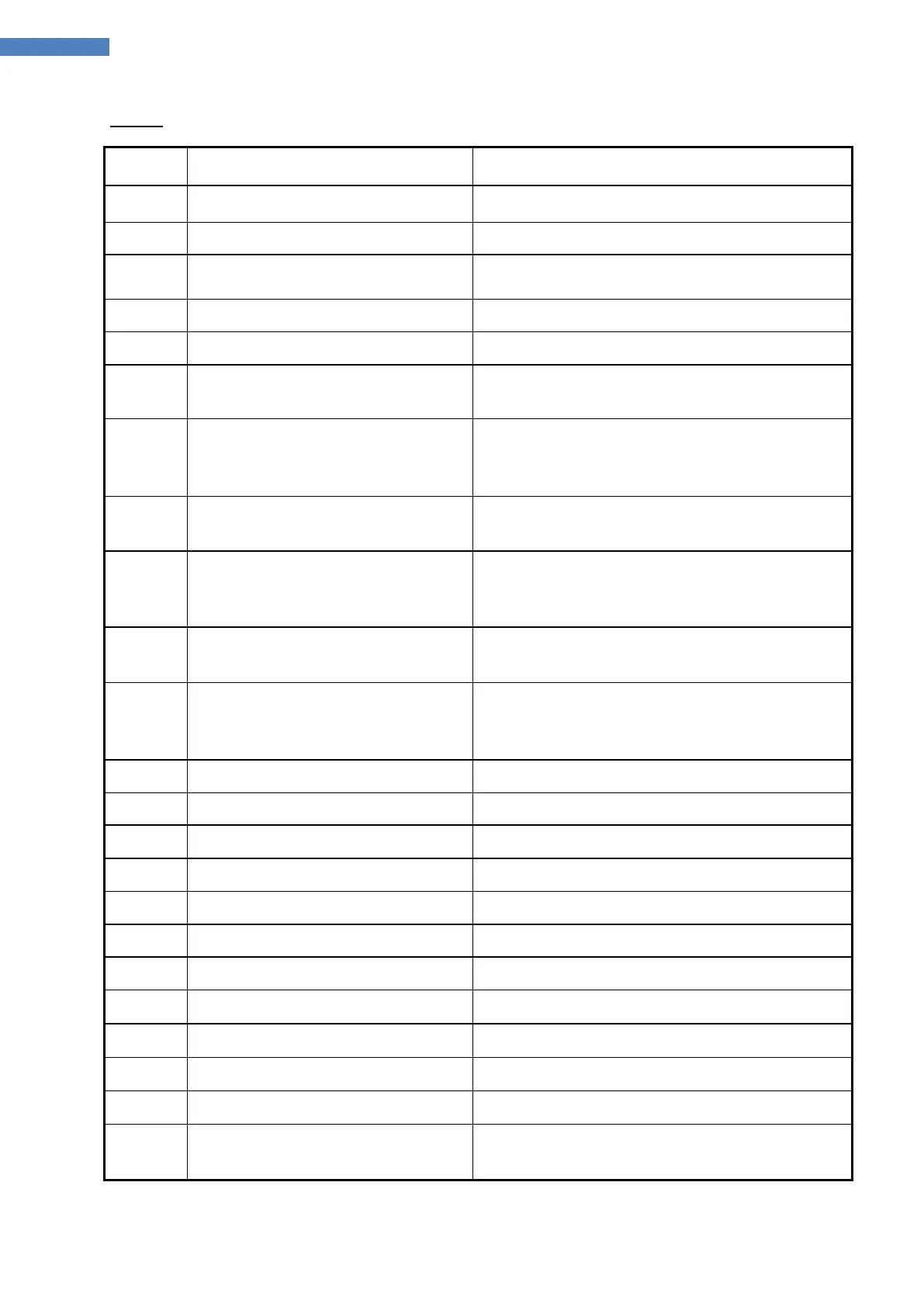

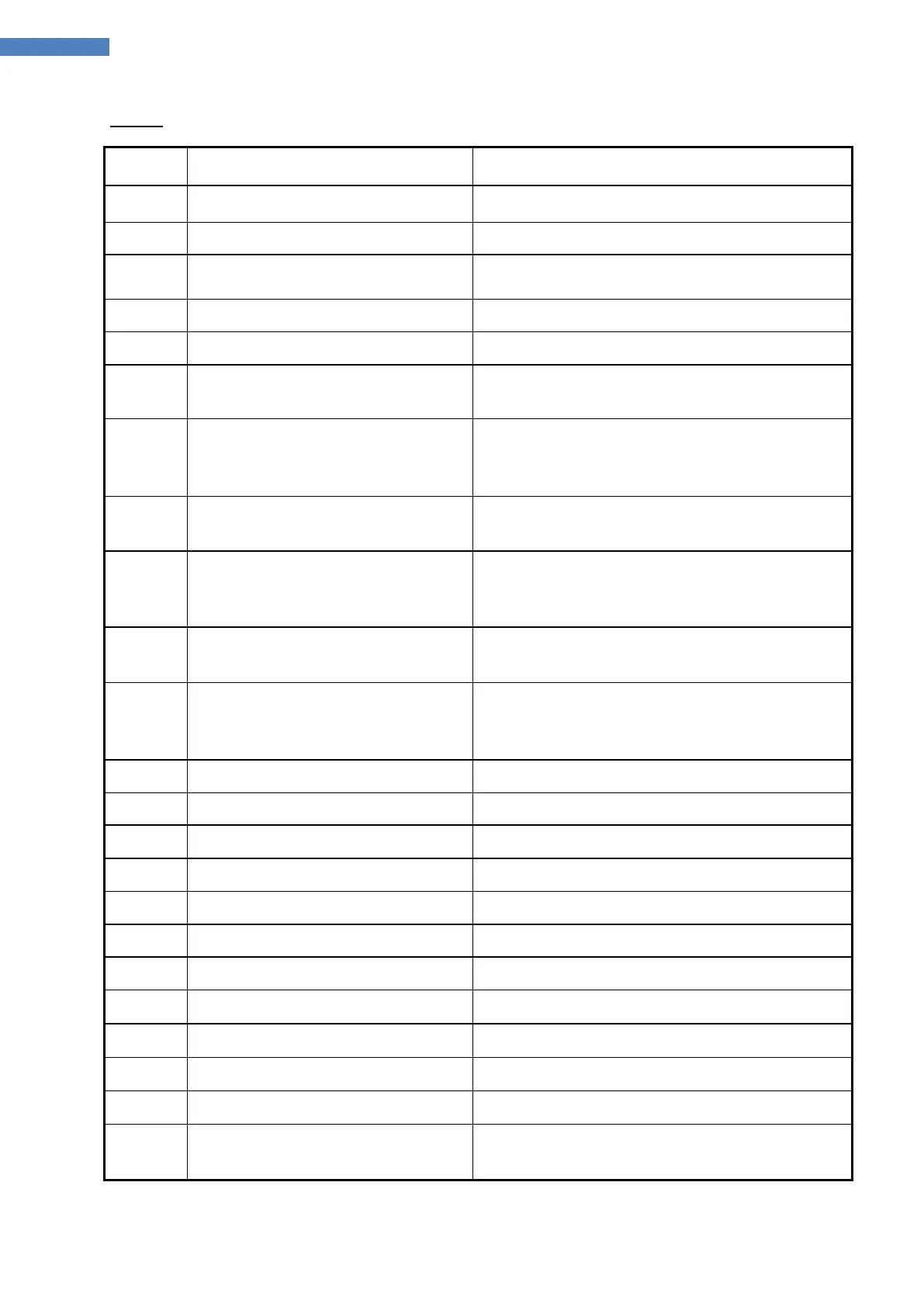

Alarms

check coolant circuit

causes: defective pump/valves/hoses, defective flow sensor, soiled filter (if present)

Motor circuit breaker has triggered

open switch cabinet and reset motor circuit breaker

causes: live components or input voltage defective

check coolant circuit

refill the coolant up to the MAX-mark (tank)

causes: leakage, evaporation, defective level switch

Misc. error 1 (definition: see circuit diagram input

E03)

depending on the function

Misc. error 2 (definition: see circuit diagram input

E04)

depending on the function

KK 1 | Low temperature alarm

temperature less than absolute limit parameter A1

protection shutdown (defined by manufacturer)

causes: defective electrical connection to compressor, defective compressor or HGB-

valve

KK 1 | High temperature alarm

temperature greater than absolute limit parameter A2

protection shutdown (defined by manufacturer)

causes:

compressor system: defective electrical connection to compressor, defective compressor

or HGB-valve, refrigerant shortage, defective fan or throughput too low (air-cooled)

Water cooled: low flow rate of external water circuit

KK 2 | Low temperature alarm

temperature less than absolute limit parameter A41

protection shutdown (defined by manufacturer)

causes: defective electrical connection to compressor, defective compressor or HGB-

valve

KK 2 | High temperature alarm

temperature greater than absolute limit parameter A42

protection shutdown (defined by manufacturer)

causes:

compressor system: defective electrical connection to compressor, defective compressor

or HGB-valve, refrigerant shortage, defective fan or throughput too low (air-cooled)

Water cooled: low flow rate of external water circuit

KK 3 | Low temperature alarm

temperature less than absolute limit parameter A51

protection shutdown (defined by manufacturer)

causes: defective electrical connection to compressor, defective compressor or HGB-

valve

KK 3 | High temperature alarm

temperature greater than absolute limit parameter A52

protection shutdown (defined by manufacturer)

causes:

compressor system: defective electrical connection to compressor, defective compressor

or HGB-valve, refrigerant shortage, defective fan or throughput too low (air-cooled)

Water cooled: low flow rate of external water circuit

Phase sequence error (wrong rotating field)

check connection of phases L1-L2-L3

cause: defective phase sequence relay

check function of fan

causes: over temperature, overload, under-/overvoltage

Temperature sensor F5 (KK 2) | short circuit

check electrical connection to sensor F5, replace sensor F5

Temperature sensor F5 (KK 2) | cable break

check electrical connection to sensor F5, replace sensor F5

Temperature sensor F6 (tank / KK 3) | short

circuit

check electrical connection to sensor F6, replace sensor F6

Temperature sensor F6 (tank / KK 3) | cable

break

check electrical connection to sensor F6, replace sensor F6

Temperature sensor F1 (KK 1) | short circuit

check electrical connection to sensor F1, replace sensor F1

Temperature sensor F1(KK 1) | cable break

check electrical connection to sensor F1, replace sensor F1

Temperature sensor F2 (ambient) | short circuit

check electrical connection to sensor F2, replace sensor F2

Temperature sensor F2 (ambient) | cable break

check electrical connection to sensor F2, replace sensor F2

Communication error with display

check electrical connection, change display or controller

restart chiller (hard power reset)

contact service hotline if necessary

causes: under-/overvoltage, data storage error, software bug, defective controller

Loading...

Loading...